Fiber reinforced composite material perforation cutter based on electroplated diamond

A kind of electroplating diamond, fiber reinforced technology, applied in the direction of cutting tools, manufacturing tools, drilling tool accessories for lathes, etc., can solve the problems of delamination, tearing and burrs, reduce friction coefficient and increase service life , The effect of preventing the accumulation of chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

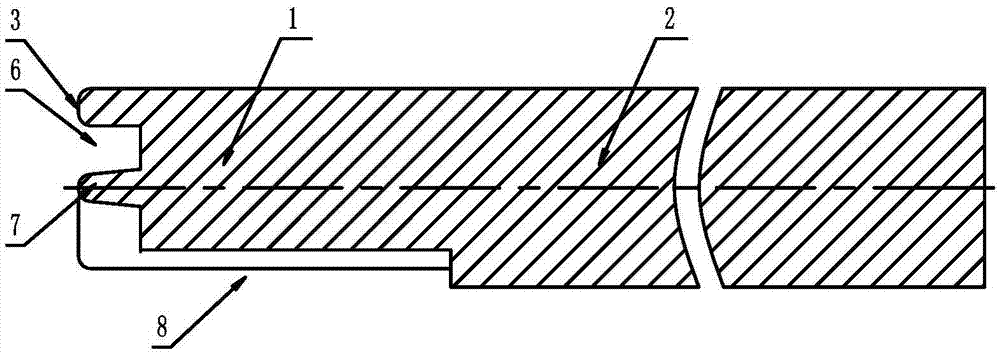

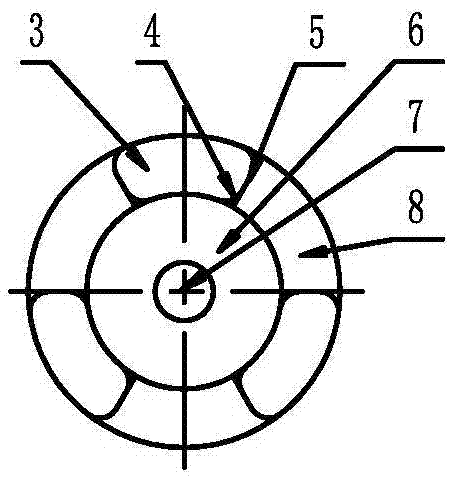

[0025] Embodiment 2: The overall structure is the same as that of Embodiment 1, and the main parameters are basically the same, the only difference is that the plane where the flank face 3 of the arc-shaped cutting part is located is coplanar with the plane where the front end of the frustum-shaped center drill 7 is located, The diameter of the front end of the truncated conical central drill 7 is 1 mm, and the conical angle of the truncated conical central drill 7 is 22°.

Embodiment 3

[0026] Embodiment 3: The overall structure is the same as that of Embodiment 1, and the main parameters are also basically the same. The only difference is that the plane where the front end of the conical center drill 7 is located is 0.5 mm protruding from the plane where the flank face 3 of the arc-shaped cutting part is located. , The diameter of the front end of the frustum-shaped center drill 7 is 1 mm, and the cone angle of the frustum-shaped center drill 7 is 27°.

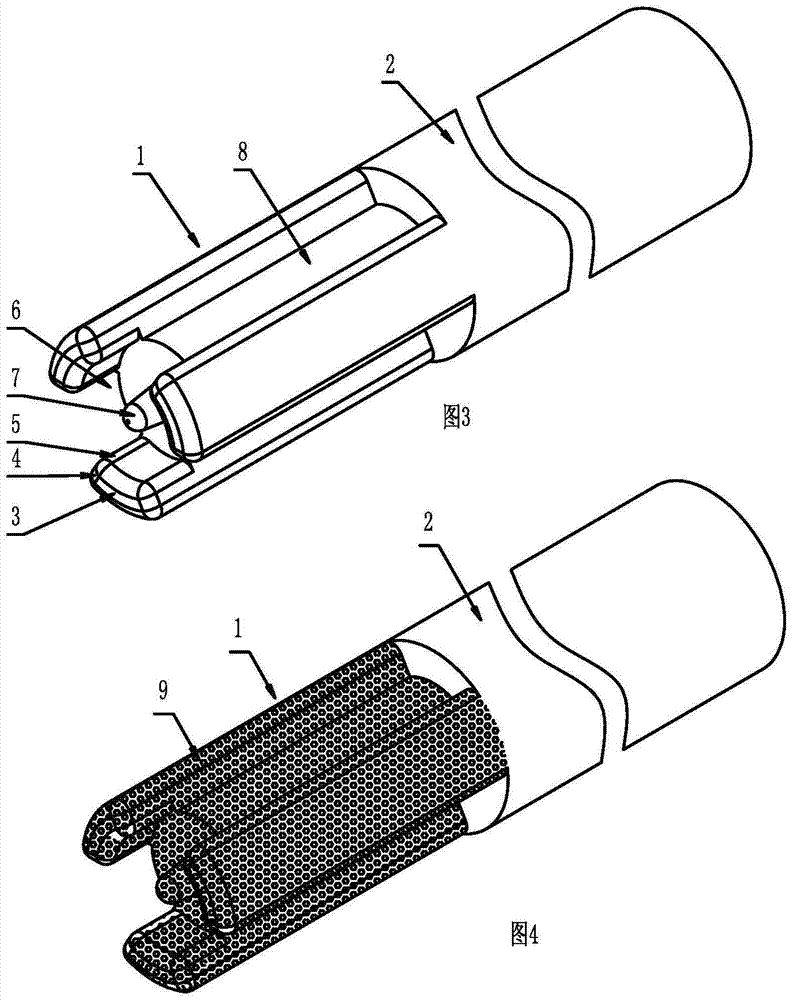

[0027] The base material of the cutting tool of the present invention is selected as metal material, as No. 45 steel can be selected for use, after quenching and tempering and surface quenching treatment, diamond particles 9 are plated on the surface. The cutting tool of the present invention has high hardness, high strength, good heat resistance and drill Good cutting performance and other advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com