Modified particle for mining cable sheath material and preparation method thereof

A cable sheath and modified particle technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of single product structure and low function enhancement, achieve high filling function, improve tear strength, and improve high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

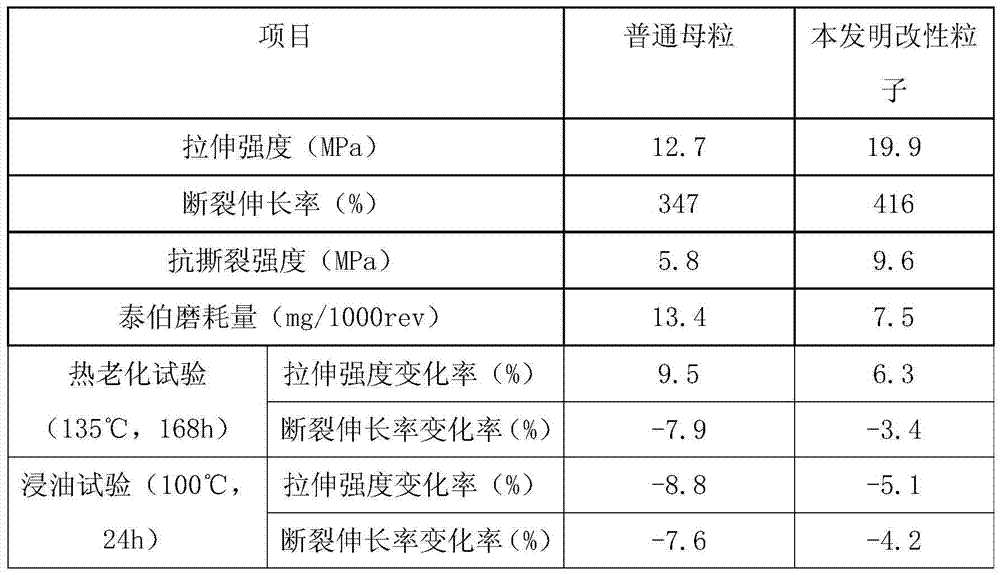

Examples

Embodiment Construction

[0014] A modified particle for mine cable sheath material, made of the following raw materials by weight (kg): carbon nanofiber 8, SMC whisker 10, polyether thermoplastic polyurethane elastomer 25, neoprene rubber 22, Tall oil modified phenolic resin 12, modified filler 13, hexamethylenetetramine 1, γ-mercaptopropyltriethoxysilane 1, ultrafine mica powder 8, basic lead carbonate 2.5, phthalic acid Butyl ester 8, 3,3'-dichloro-4,4'-diaminodiphenylmethane 1.5, vulcanized crosslinking agent SQS6341.5, zinc dimethacrylate 2.5;

[0015] The preparation method of described modified filler is as follows: a, get the raw material of following weight (kg): walnut sand 22, periclase 15, waste ceramic chip 11, vinyl acetate 20, styrene 25, butyl acrylate 8, pass Ammonium sulfate 0.3, sodium bicarbonate 0.1 sodium lauryl sulfate 0.8, emulsifier OP-100.6, γ-methacryloxypropyl trimethoxysilane 1.5, vinyl triethoxysilane 1.2, wool wax 30 , monoglyceride succinate 12, polyadipate neopentyl gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com