Amorphous carbon composite coating and preparation method and application thereof

A composite coating, amorphous carbon technology, applied in the field of wear-resistant coatings, can solve the problems of poor matching between the joint head and the socket interface, limited service life of artificial joints, affecting the quality of life of patients, etc. , convenient for continuous industrial production, easy to popularize and utilize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

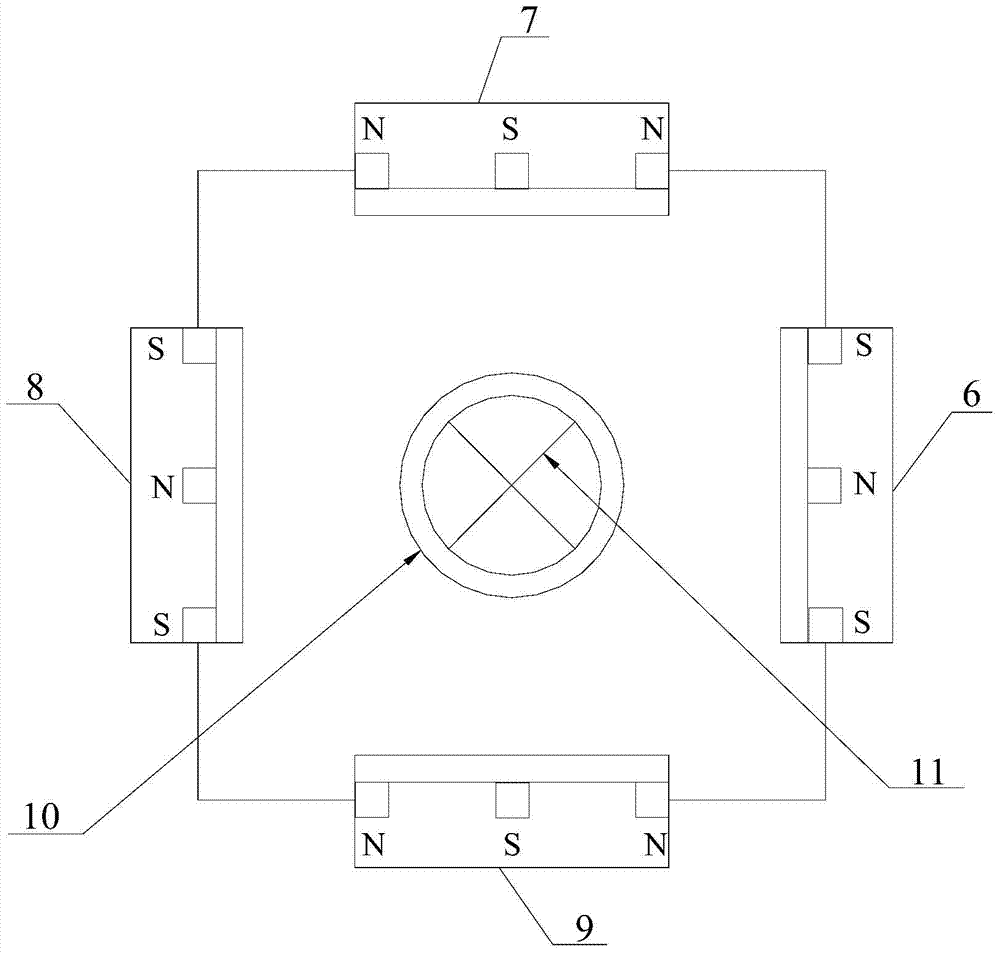

[0040] The amorphous carbon composite coating prepared by the closed-field unbalanced magnetron sputtering method adopts the device for realizing the preparation method of the amorphous carbon composite coating of the present invention in the specific embodiment, and the preparation steps are as follows:

[0041]1) Select medical ultra-high molecular weight polyethylene (UHMWPE) as the matrix, place the matrix on the sample holder 11 on the sample stage 10, the first graphite target 6 is the working target, the first titanium target 7, the second graphite target 8 , The second titanium target 9 is a non-working target, but maintain a small current state of 0.25A to prevent the target from being polluted during the coating process, adjust the distance between the first graphite target and the substrate, adjust the distance to 10cm, and the sample stage 10 The revolution is kept closed, and the rotation rate of the sample holder 11 is 15rpm;

[0042] Pre-evacuate the chamber to ...

Embodiment 2

[0050] The amorphous carbon composite coating prepared by the closed-field unbalanced magnetron sputtering method adopts the device for realizing the preparation method of the amorphous carbon composite coating of the present invention in the specific embodiment, and the preparation steps are as follows:

[0051] 1) Select medical ultra-high molecular weight polyethylene (UHMWPE) as the matrix, place the matrix on the sample holder 11 on the sample stage 10, the first graphite target 6 is the working target, the first titanium target 7, the second graphite target 8 , The second titanium target 9 is a non-working target, but maintain a small current state of 0.25A to prevent the target from being polluted during the coating process, adjust the distance between the first graphite target and the substrate, adjust the distance to 10cm, and the sample stage 10 The revolution is kept closed, and the rotation rate of the sample holder 11 is 15rpm;

[0052] Pre-evacuate the chamber to...

Embodiment 3

[0059] The amorphous carbon composite coating prepared by the closed-field unbalanced magnetron sputtering method adopts the device for realizing the preparation method of the amorphous carbon composite coating of the present invention in the specific embodiment, and the preparation steps are as follows:

[0060] 1) Select medical ultra-high molecular weight polyethylene (UHMWPE) as the matrix, place the matrix on the sample holder 11 on the sample stage 10, the first graphite target 6 is the working target, the first titanium target 7, the second graphite target 8 , The second titanium target 9 is a non-working target, but maintain a small current state of 0.25A to prevent the target from being polluted during the coating process, adjust the distance between the first graphite target and the substrate, adjust the distance to 10cm, and the sample stage 10 The revolution is kept closed, and the rotation rate of the sample holder 11 is 15rpm;

[0061] Pre-evacuate the chamber to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com