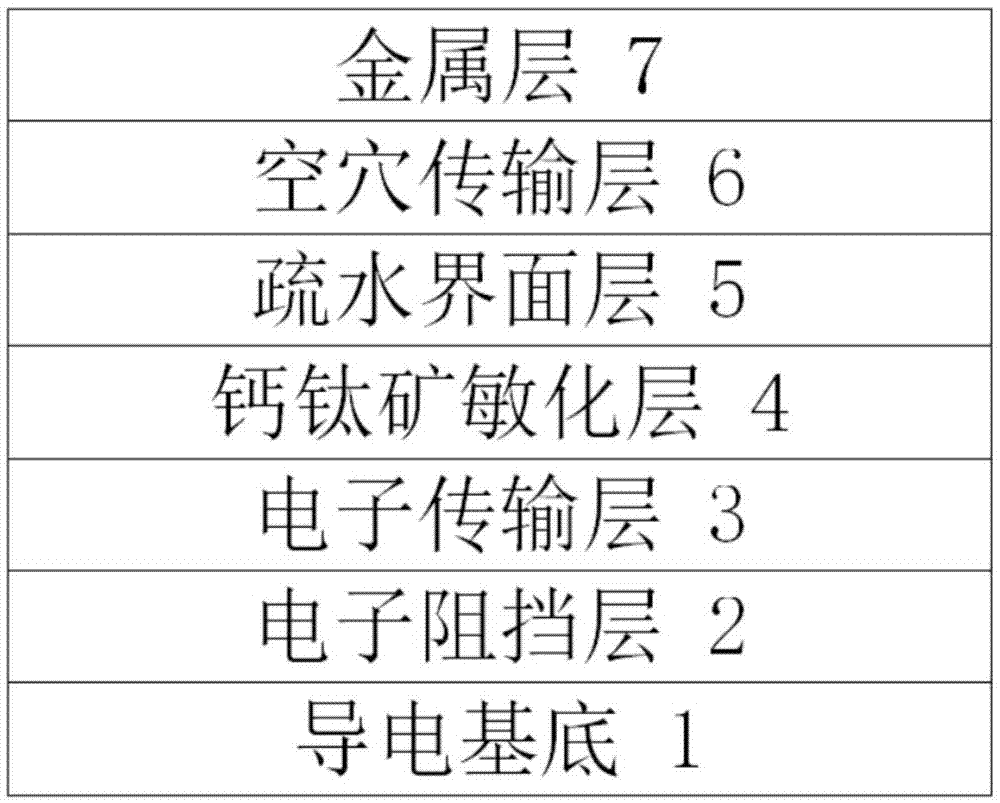

Perovskite solar cell with stable performance in air environment and preparation method of perovskite solar cell

A solar cell and air environment technology, applied in the manufacture/processing of organic semiconductor devices, circuits, photovoltaic power generation, etc., can solve problems such as ineffective effects, easy decomposition, and dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Choose FTO glass as the substrate, wash it with detergent, acetone, ethanol in sequence, and then dry it.

[0040] 2. Electron blocking layer and electron transport layer

[0041] Tetrabutyl titanate and ethylenediamine were dissolved in water and ethanol to prepare a titanium dioxide sol, which was spin-coated on the FTO substrate at a rotation speed of 4000r.p.m for 30s, and then dried on a hot stage at 80°C for 5min. The material was diluted in ethanol, and spin-coated on the FTO substrate containing titanium dioxide sol at a rotation speed of 4000r.p.m for 30s, then annealed at 120°C for 5min, and then the prepared electron transport layer was sintered at 500°C for 30min.

[0042] 3. CH 3 NH 3 PB 3 Preparation of perovskite layer

[0043] (1) Synthesis of CH 3 NH 3 I

[0044] Place a round-bottomed flask containing 30ml of methylamino alcohol solution in ice water at 0°C, add 33ml of hydroiodic acid while stirring into the flask, and continue to react in a...

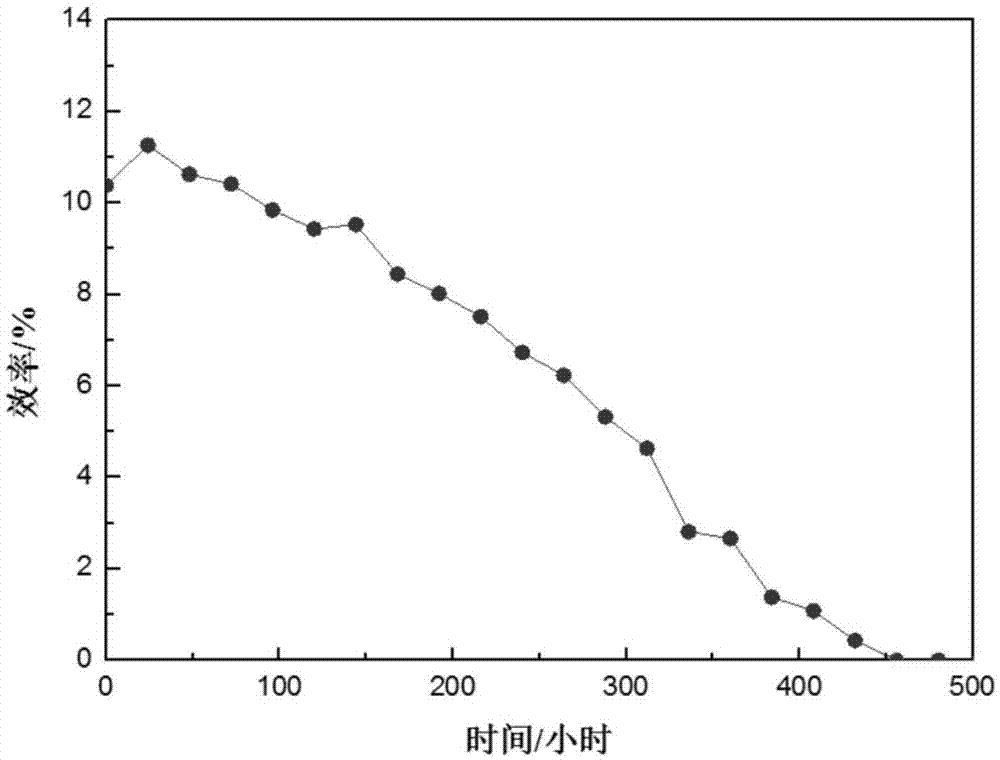

Embodiment 2

[0055] 1. Choose FTO glass as the substrate, wash it with detergent, acetone, ethanol in sequence, and then dry it.

[0056] 2. Preparation of electron blocking layer and electron transport layer

[0057] With step 2 in embodiment 1

[0058] 3. CH 3 NH 3 PB 3 Preparation of perovskite layer

[0059] With step 3 in embodiment 1

[0060] 4. Preparation of hydrophobic interface layer

[0061] Dissolve tridecafluorooctyltriethoxysilane in isopropanol, then heat at 80°C for 30min to obtain a 1wt% alcoholyzed fluorosilane solution, and in a glove box, dissolve the alcoholyzed fluorosilane solution Spin coating on the perovskite layer, the rotation speed is 6000r.p.m, and the time is 30s.

[0062] 5. Preparation of hole transport layer

[0063] Same as step 5 in Example 1.

[0064] 6. Preparation of metal layer

[0065] Same as step 6 in Example 1.

[0066] Implementation effect: Finally, the performance test of the battery is carried out, at AM1.5, 100mW / cm 2 The test wa...

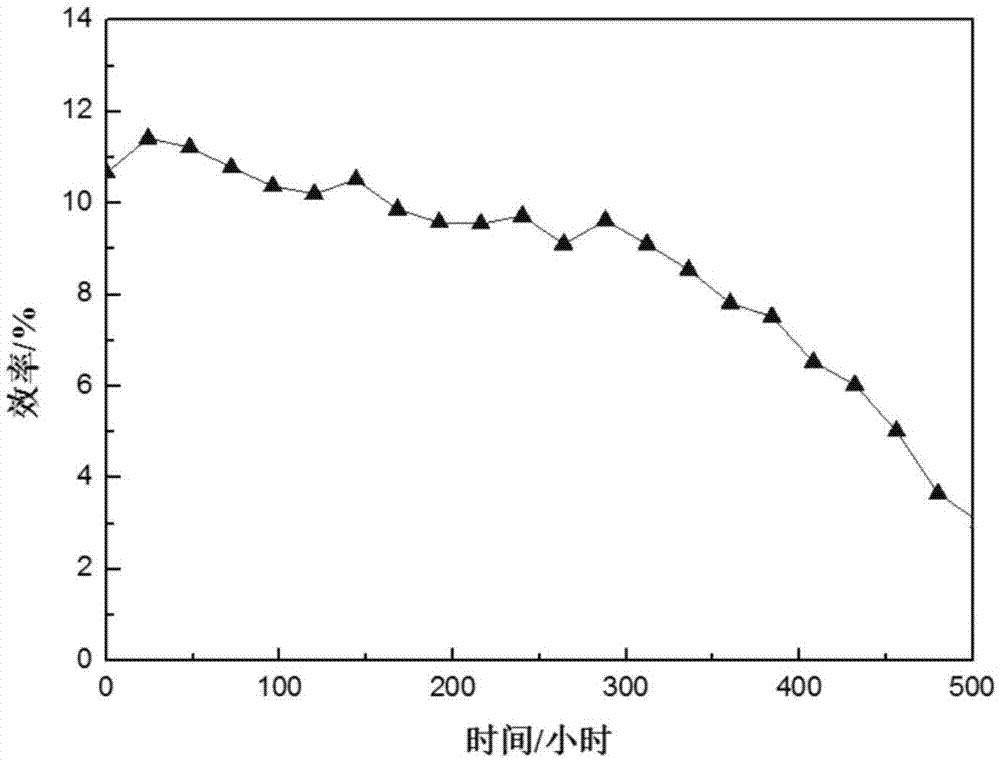

Embodiment 3

[0068] 1. Choose FTO glass as the substrate, wash it with detergent, acetone, ethanol in sequence, and then dry it.

[0069] 2. Preparation of electron blocking layer and electron transport layer

[0070] With step 2 in embodiment 1

[0071] 3. CH 3 NH 3 PB 3 Preparation of perovskite layer

[0072] With step 3 in embodiment 1

[0073] 4. Preparation of hydrophobic interface layer

[0074] Dissolve tridecafluorooctyltriethoxysilane in isopropanol, and then heat at 80°C for 30 minutes to obtain a 2wt% alcoholyzed fluorosilane solution. In a glove box, the alcoholyzed fluorosilane solution Spin coating on the perovskite layer, the rotation speed is 6000r.p.m, and the time is 30s.

[0075] 5. Preparation of hole transport layer

[0076] Same as step 5 in Example 1.

[0077] 6. Preparation of metal layer

[0078] Same as step 6 in Example 1.

[0079] Implementation effect: Finally, the performance test of the battery is carried out, at AM1.5, 100mW / cm 2 The test was ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com