Fully-biodegradable polylactic acid thermoplastic elastomer and preparing method thereof

A thermoplastic elastomer, polylactic acid technology, applied in the field of polylactic acid thermoplastic elastomer and its preparation, can solve the problems of uneven particle size, environmental pollution, lack of biocompatibility, etc., and achieve good biocompatibility, The effect of simple preparation process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

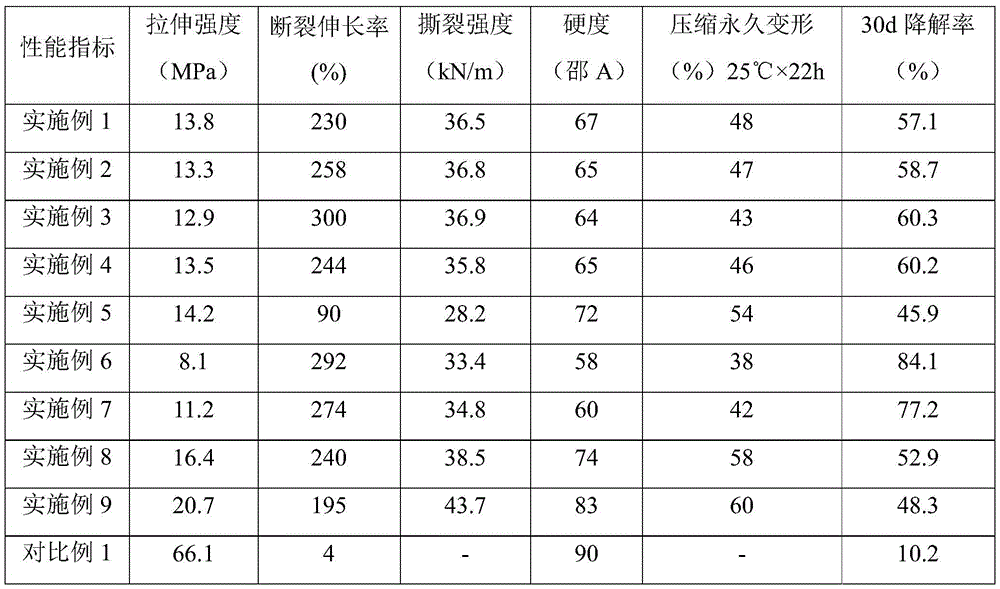

Examples

Embodiment 1

[0047] Add 10 parts (parts by mass, the same below) acetyl tri-n-butyl citrate to 100 parts of dried bio-based vulcanized polyester rubber particles for oil extension to obtain oil-extended bio-based vulcanized polyester rubber particles;

[0048] 65 parts of oil-extended bio-based vulcanized polyester rubber particles, 35 parts of poly-L-lactic acid, and 1.3 parts of carbodiimide anti-hydrolysis agent UN-150 were prepared by high-temperature melt blending in an internal mixer to obtain fully biodegradable polylactic acid thermoplastic elastomer.

[0049] The working temperature of the internal mixer is 180° C., and the mixture is mixed at 60 rpm for 10 minutes until the mixing torque is balanced.

Embodiment 2

[0051] Add 12.56g (0.165mol) 1,3-propanediol, 14.87g (0.165mol) 1,4-butanediol and 4.61g (0.039mol) Succinic acid, 31.55 g (0.156 mol) of sebacic acid, and 12.19 g (0.105 mol) of fumaric acid were heated to 180° C. under nitrogen protection and stirring, and esterified for 1 hour to obtain a polyester prepolymer. Add 75.8 mg of p-toluenesulfonic acid and 151.6 mg of p-benzoquinone to the polyester prepolymer obtained above, heat up to 220 ° C, gradually reduce the pressure in the reaction device from 1 atmospheric pressure to 1500 Pa, and react for 2.5 hours. The obtained bio-based aliphatic unsaturated polyester has a number average molecular weight of 4132, a weight average molecular weight of 7478 and a polydispersity coefficient of 1.81. After cooling down to 150°C, add 3.7890g of pentaerythritol tetra(meth)acrylate and 6.0624g of polyethylene glycol 400 monooleate, stir evenly, and after cooling, a paste-like bio-based aliphatic unsaturated polyester mixture is obtained ...

Embodiment 3

[0061] 40 parts of acetyl tri-n-butyl citrate are added to 100 parts of dried bio-based vulcanized polyester rubber particles for oil extension to obtain oil-extended bio-based vulcanized polyester rubber particles;

[0062] 65 parts of oil-extended bio-based vulcanized polyester rubber particles, 35 parts of poly-L-lactic acid, and 1.3 parts of carbodiimide anti-hydrolysis agent UN-150 were prepared by high-temperature melt blending in an internal mixer to obtain fully biodegradable polylactic acid thermoplastic elastomer.

[0063] The working temperature of the internal mixer is 180° C., and the mixture is mixed at 60 rpm for 10 minutes until the mixing torque is balanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com