Temperature and humidity regulating type composite coating material and preparation method thereof

A technology for composite coating, temperature regulation and humidity regulation, which is applied in the direction of coating, antifouling/underwater paint, paint containing biocide, etc. effect, poor thermal conductivity, etc., to achieve the effect of good humidity control, fast dehumidification, and high moisture absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

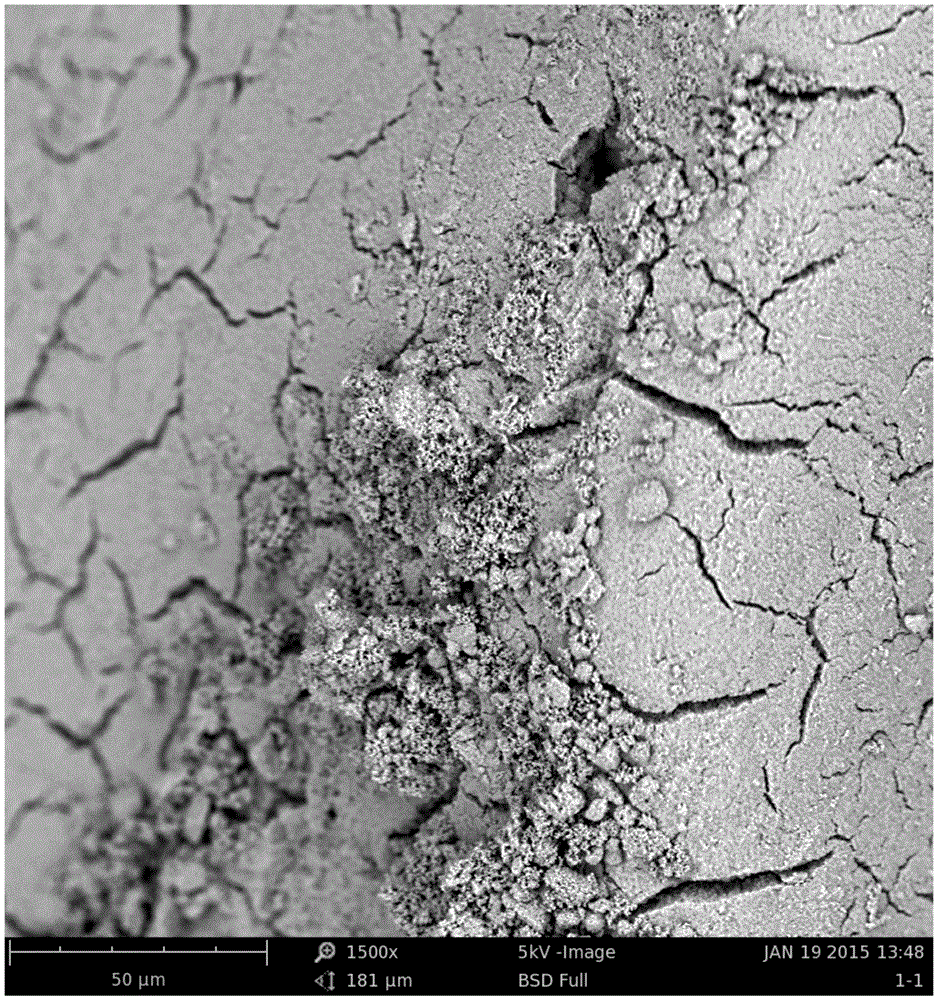

[0030] Modified zeolite filler: prepared from natural zeolite after activation and heating with 3% sodium chloride solution assisted by 100w microwave for 3min.

[0031] Shaping phase change material: composed of paraffin wax and graphite in a weight ratio of 10:1.

[0032] Add 0.5 parts of alcohol ester 12 into the reaction kettle, add 5 parts of water and stir, then add 0.5 parts of defoamer, 0.5 parts of dispersant and continue stirring for about 10 minutes; Slowly drop into the reaction kettle, stir for about 10 minutes, heat the water temperature to 60-75°C, and react for 20 minutes. After the reaction, cool the reaction pot with cooling water to lower the temperature to 20-30°C; The zeolite filler is put into a grinder and ground until the 200-mesh screen can be completely leaked, and then sent to an oven to be heated at 80°C for 2 hours for later use; 5 parts of titanium dioxide, 5 parts of shaped phase change materials and 10 parts of modified Slowly sieve the zeolite...

Embodiment 2

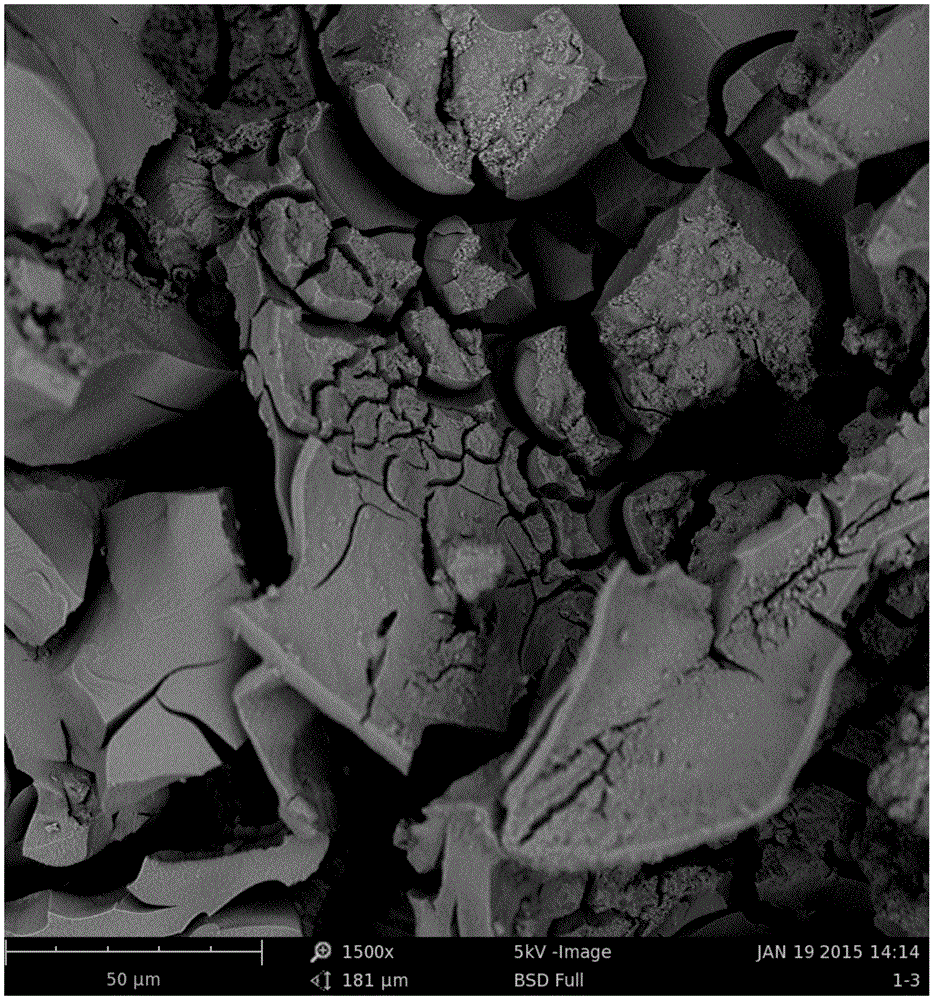

[0034] Modified zeolite filler: prepared from natural zeolite after activation and heating with 200w microwave-assisted 6% sodium chloride solution for 5 minutes.

[0035] Shaping phase change material: composed of paraffin wax and graphite in a weight ratio of 10:4.

[0036]Add 0.5 parts of alcohol ester 12 into the reaction kettle, add 5 parts of water and stir, then add 0.5 parts of defoamer, 0.5 parts of dispersant and continue stirring for about 10 minutes; Slowly drop into the reaction kettle, stir for about 10 minutes, heat the water temperature to 60-75°C, and react for 20 minutes. After the reaction, cool the reaction pot with cooling water to lower the temperature to 20-30°C; The zeolite filler is put into a grinder and ground until the 200-mesh screen can be completely leaked, and then sent to an oven to be heated at 80°C for 2 hours for later use; 5 parts of titanium dioxide, 5 parts of shaped phase change materials and 10 parts of modified Slowly sieve the zeolit...

Embodiment 3

[0038] Modified zeolite filler: prepared from natural zeolite after activation and heating with 1% sodium chloride solution for 5 minutes by 200w microwave.

[0039] Shaping phase change material: composed of paraffin wax and graphite in a weight ratio of 10:2.

[0040] Add 0.5 parts of alcohol ester 12 into the reaction kettle, add 5 parts of water and stir, then add 0.5 parts of defoamer, 0.5 parts of dispersant and continue stirring for about 10 minutes; Slowly drop into the reaction kettle, stir for about 10 minutes, heat the water temperature to 60-75°C, and react for 20 minutes. After the reaction, cool the reaction pot with cooling water to lower the temperature to 20-30°C; The zeolite filler is put into a grinder and ground until the 200-mesh screen can be completely leaked, and then sent to an oven to be heated at 80°C for 2 hours for later use; 10 parts of titanium dioxide, 10 parts of shaped phase-change materials and 30 parts of modified Slowly sieve the zeolite p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com