C-direction sapphire polishing solution and preparation method thereof

A polishing liquid and sapphire technology, which is applied in the field of sapphire polishing, can solve the problems of increasing the workload of the production line, high consumption of 1,000 pieces, affecting the quality of sapphire, etc., and achieves the effect of easy control of process parameters and simplified process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

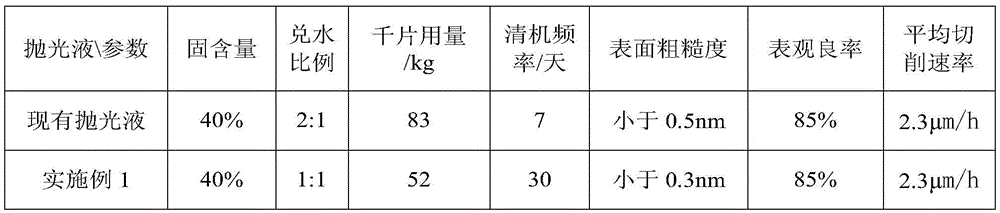

Examples

Embodiment 1

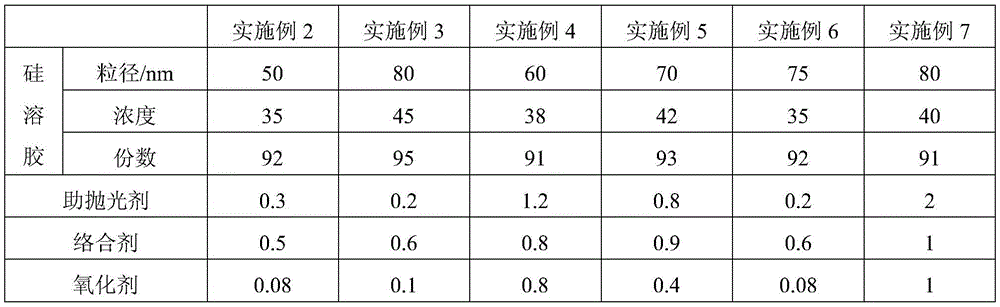

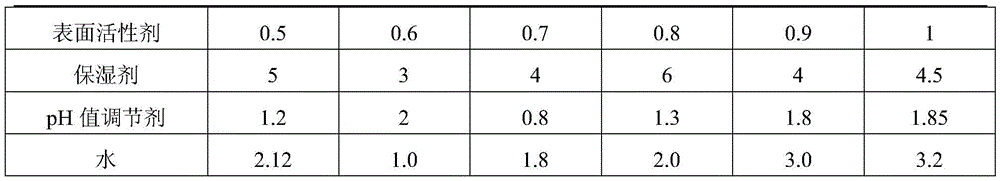

[0023] A novel sapphire C-direction polishing liquid is made from the following raw materials in parts by weight:

[0024] 92 parts of silica sol, 0.3 part of polishing aid, 0.5 part of complexing agent, 0.08 part of oxidizing agent, 0.5 part of surfactant, 5 parts of humectant, 0.5 part of pH regulator and 1.62 parts of deionized water.

[0025] The particle diameter of the silica sol is 50nm, and its concentration is 40%.

[0026] The polishing aid is prepared by mixing potassium chloride, potassium iodide and sodium fluoride in a weight ratio of 1:1:1.

[0027] The complexing agent is prepared by mixing diethylenetriamine and dihydroxyethylethylenediamine according to a weight ratio of 2:1.

[0028] The oxidant is prepared by mixing sodium hypochlorite, sodium perborate, peracetic acid and potassium perborate in a weight ratio of 1:2:2:1.

[0029] The surfactant is prepared by mixing octylphenol polyoxyethylene ether, sodium polyacrylate and sodium dodecylbenzenesulfonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com