Preparation method of flexible porous carbon fiber

A technology of porous carbon fiber and carbon fiber, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of high cost, low specific surface area, and low output, and achieve the effect of good flexibility, high specific surface area, and high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of preparation method of flexible porous carbon fiber, comprises steps as follows:

[0042] 1) washing and drying the cotton thread with a diameter of 20 microns;

[0043] 2) heat-treating the cotton thread treated in step 1) at 1000 degrees centigrade for 20 minutes in a hydrogen atmosphere with a flow rate of 50 milliliters per minute to obtain flexible and porous carbon fibers.

[0044] figure 1 It is a digital photo of the flexible porous carbon fiber prepared in this example. Depend on figure 1 It can be seen that porous carbon fiber has good flexibility and can be bent and woven into various shapes at will.

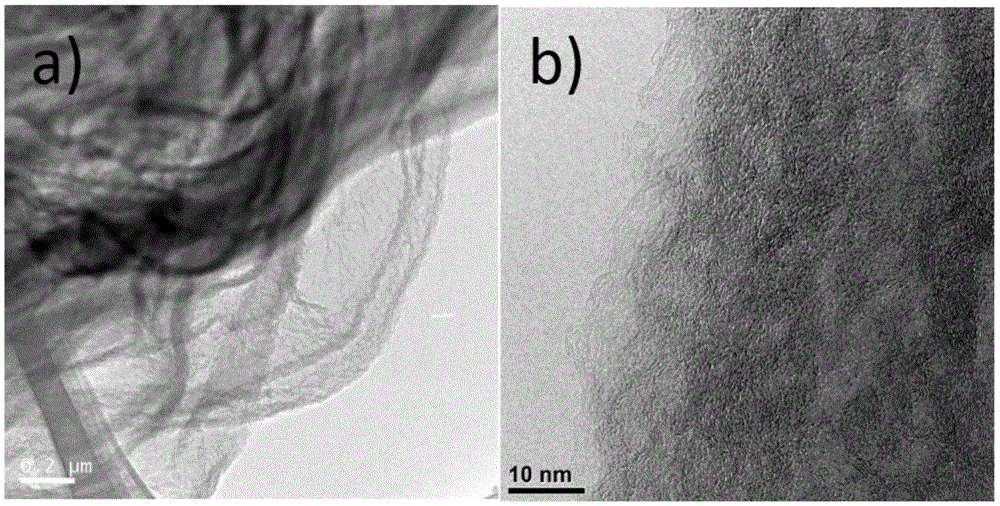

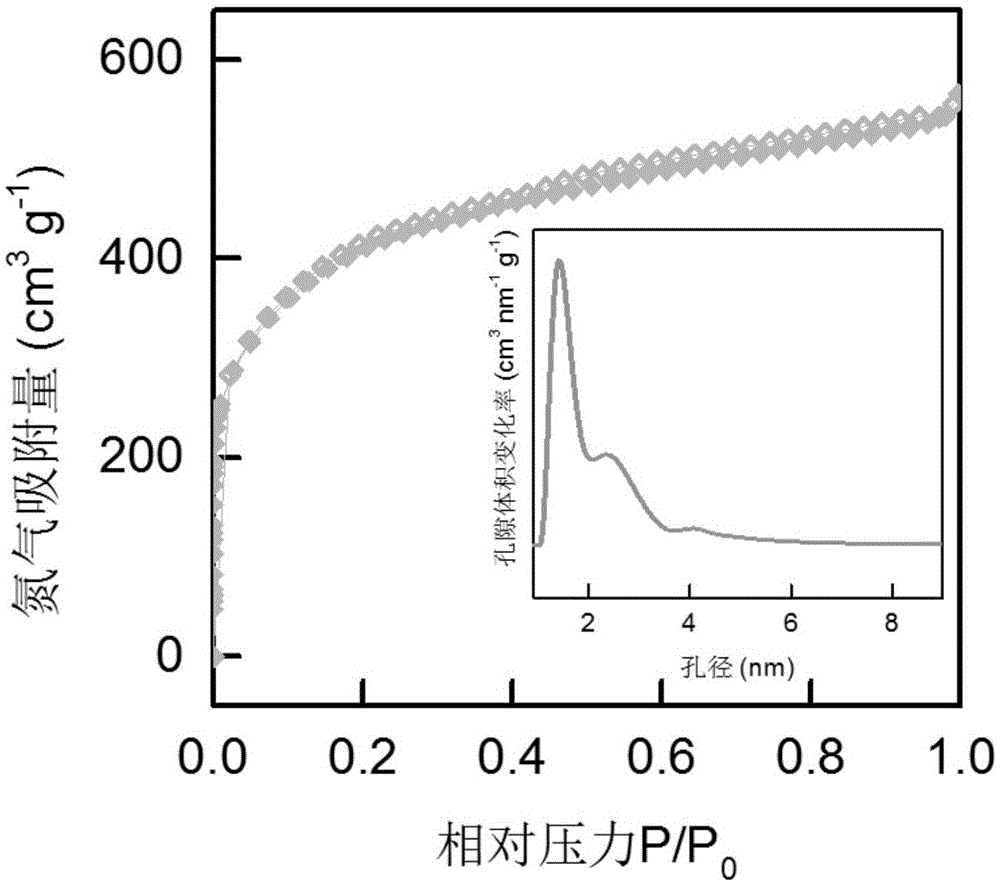

[0045] figure 2 It is a transmission electron microscope (TEM) photo of the flexible porous carbon fiber prepared in this embodiment. Depend on figure 2 a It can be seen that carbon fiber is a loose structure, which is formed by winding a large number of layered structures. exist figure 2 In the high-resolution electron microscope photo of b...

Embodiment 2

[0048] A kind of preparation method of flexible porous carbon fiber, comprises steps as follows:

[0049] 1) washing and drying the twine with a diameter of 500 microns;

[0050] 2) Heat-treat the twine treated in step 1) at 1000 degrees Celsius for 60 minutes in an ammonia gas atmosphere with a flow rate of 20 milliliters per minute to obtain flexible and porous carbon fibers.

Embodiment 3

[0052] A kind of preparation method of flexible porous carbon fiber, comprises steps as follows:

[0053] 1) Wash and dry the paper thread with a diameter of 1000 microns;

[0054] 2) heat-treating the paper thread treated in step 1) at 1000 degrees centigrade for 20 minutes in a water vapor atmosphere with a flow rate of 30 milliliters per minute to obtain flexible and porous carbon fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com