Ceramic filler for wastewater treatment, production method for ceramic filler and wastewater treatment device

A technology for sewage treatment and production methods, applied in water/sludge/sewage treatment, special compound water treatment, chemical instruments and methods, etc. Low utilization rate and other problems, to achieve the effect of reducing follow-up processing costs, improving recycling utilization rate, and high carbon source utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

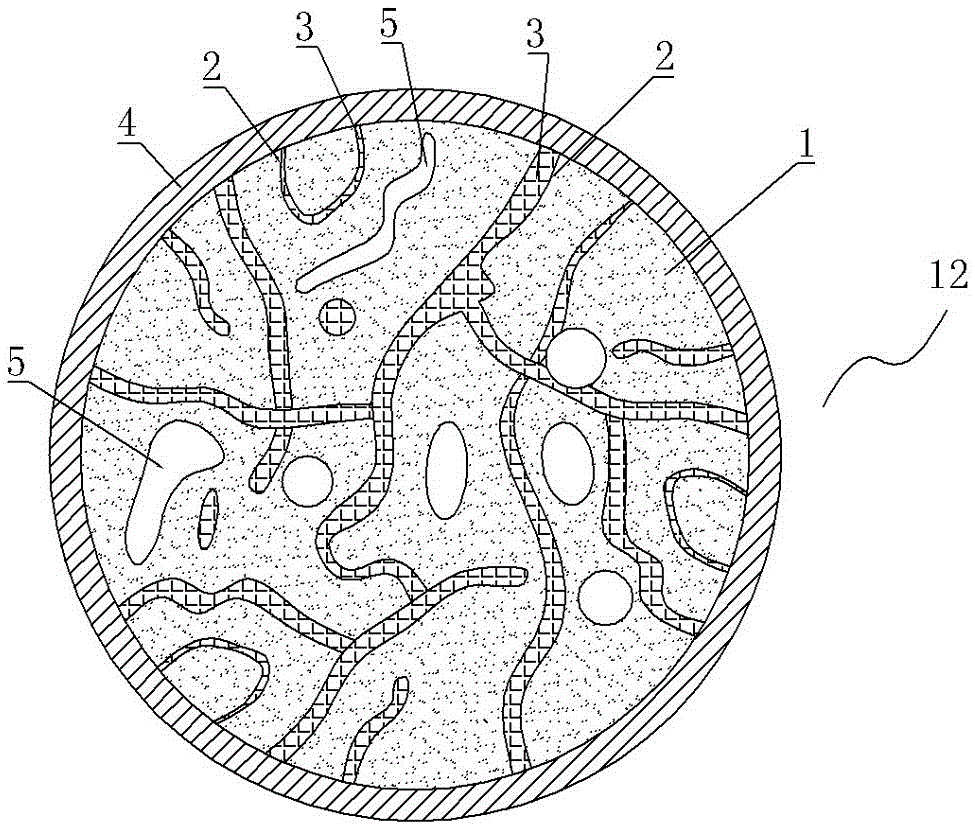

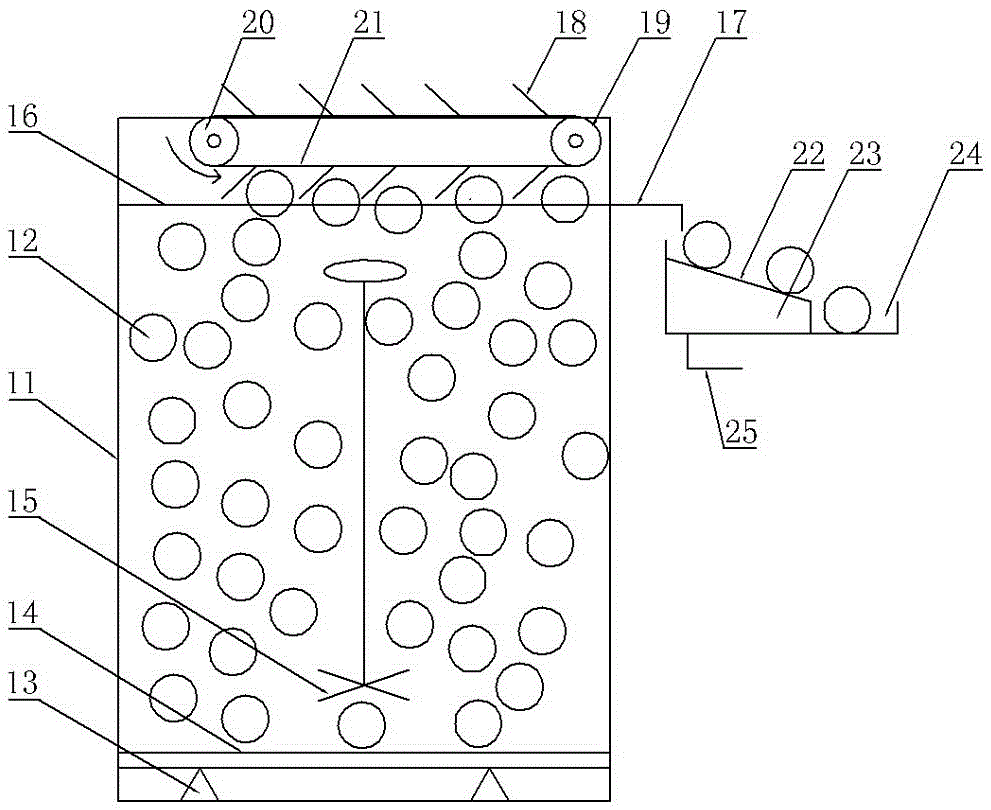

[0035]Step 1: first process ceramsite, and process clay, coal gangue, dried sludge and bamboo powder into ceramsite with micropores communicating with the outside through the method of burning and calcining. The moisture content of dried sludge is 30%; the specific processing process is:

[0036] (1) Pretreatment, put 100 parts by mass of raw materials into a ball mill and add water for ball milling. After ball milling, the mud is dehydrated and dried to form mud lumps, and then the mud lumps are broken into powdery mud to control the amount of mud. The fineness is 80 meshes, wherein the raw materials with a total mass fraction of 100 parts include 5 parts of dried sludge, 79 parts of clay and 16 parts of coal gangue;

[0037] (2) Add powdery mud and water into the molding machine to generate raw ceramsite, the mass fraction of water is 20%, and the particle size of raw ceramsite is 1.0cm;

[0038] (3) Calcination, put the raw ceramsite in an oven, gradually raise the tempera...

Embodiment 2

[0046] Step 1: first process ceramsite, and process clay, coal gangue, dried sludge and bamboo powder into ceramsite with micropores communicating with the outside through the method of burning and calcining. The moisture content of dried sludge is 35%; the specific processing process is:

[0047] (1) Pretreatment, put 100 parts by mass of raw materials into a ball mill and add water for ball milling. After ball milling, the mud is dehydrated and dried to form mud lumps, and then the mud lumps are broken into powdery mud to control the amount of mud. The fineness is 20 meshes, wherein the raw materials with a total mass fraction of 100 parts include 30 parts of dried sludge, 5 parts of bamboo powder, 32.5 parts of clay and 32.5 parts of coal gangue;

[0048] (2) Add powdery mud and water into the molding machine to generate raw ceramsite, the mass fraction of water is 60%, and the particle size of raw ceramsite is 2.0cm;

[0049] (3) Calcination, place the raw material cerams...

Embodiment 3

[0058] Step 1: first process ceramsite, and process clay, coal gangue, dried sludge and bamboo powder into ceramsite with micropores communicating with the outside through the method of burning and calcining. The moisture content of dried sludge is 40%; the specific processing process is,

[0059] (1) Pretreatment, put 100 parts by mass of raw materials into a ball mill and add water for ball milling. After ball milling, the mud is dehydrated and dried to form mud lumps, and then the mud lumps are broken into powdery mud to control the amount of mud. The fineness is 50 meshes, wherein the total mass fraction is 100 parts of raw materials including 17.5 parts of dried sludge, 2.5 parts of bamboo powder, 60 parts of clay and 20 parts of coal gangue;

[0060] (2) Add powdery mud and water into the molding machine to generate raw ceramsite, the mass fraction of water is 40%, and the particle size of raw ceramsite is 1.5cm;

[0061] (3) Calcination, place the raw material ceramsit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com