Water-in-water colorful coating and preparation method thereof

A multi-color paint, water-type technology, applied in the direction of coating, can solve the problems of not considering the waterproof, anti-pollution and easy cleaning of multi-color paint, and the process is not simple enough, so that it is not easy to external interference and the gel system is stable. , to ensure the effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

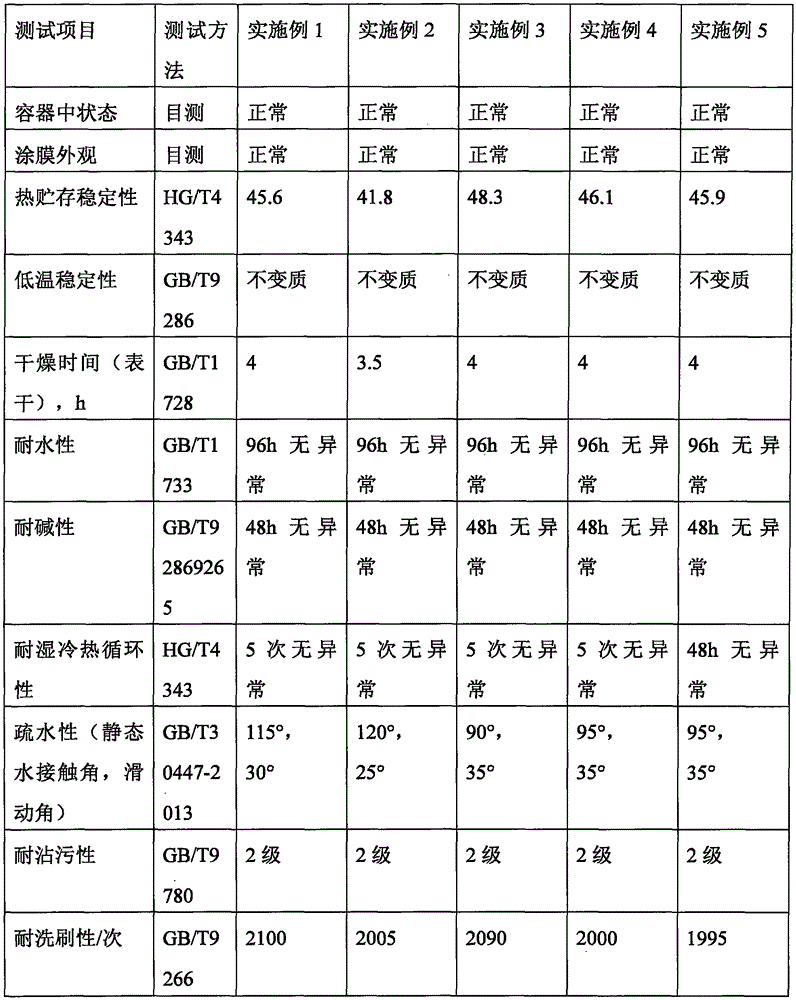

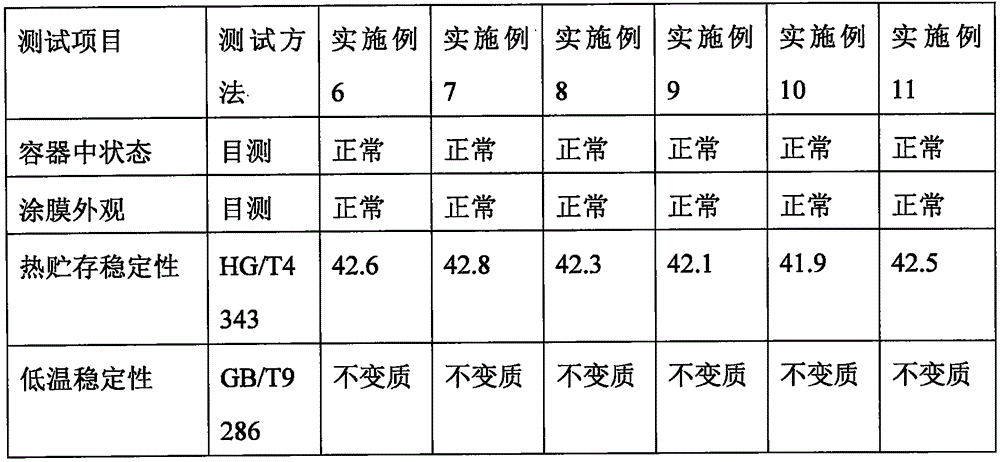

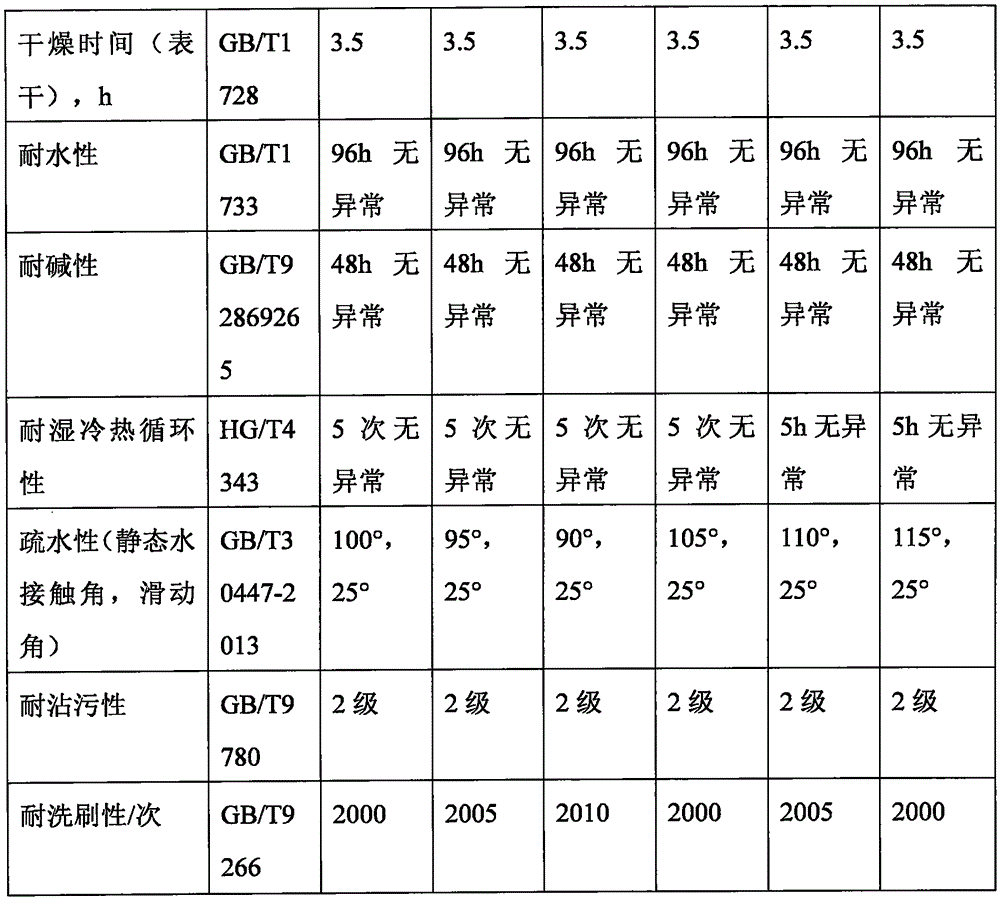

Examples

preparation example Construction

[0037] A kind of preparation method of water-in-water type colorful paint, it comprises steps:

[0038] S100 to prepare a colloidal solution, add corresponding mass parts of sodium pyrophosphate and dissolve in water under stirring, after the sodium pyrophosphate is completely dissolved, add lithium magnesium silicate powder and dissolve in it to form a colloidal solution, wherein the stirring speed is set to 800~1000r / min, stirring time is 100~150min;

[0039] S200 Prepare the granulated base paint of the dispersed phase, stir the mixed solution of water and emulsion in corresponding parts by mass, add wetting and dispersing agent, defoamer, film-forming agent, propylene glycol, cellulose under stirring, adjust the stirring speed after stirring Add at least one pigment, after stirring, adjust the stirring speed and add hydrophobic modifier and colloidal solution to form a dispersed phase of granulated base paint;

[0040] S300 granulation, adding colloidal solution and granu...

Embodiment 1

[0050] A kind of preparation method of water-in-water type colorful paint, comprises the following steps:

[0051] 1. Preparation of colloidal solution: set the stirring speed at 900r / min, add 90 parts of water weight and 2 parts of sodium pyrophosphate into the mixing container under stirring, after the sodium pyrophosphate is completely dissolved, add 7 parts of lithium magnesium silicate powder , stirring for 120min;

[0052] 2. Preparation of granulated base paint: Add 400 parts of water and 200 parts of styrene-acrylic emulsion into another mixing container, set the stirring speed at 800r / min, add 6 parts of sodium polyacrylate, 4 parts of defoamer, 5 parts of film-forming agent, 10 parts of propylene glycol, 5 parts of cellulose, stir for 30 minutes; set the stirring speed at 1000r / min, add 10 parts of titanium dioxide and 25 parts of titanium chrome brown under stirring, and stir for 30 minutes; set the stirring speed at 400r / min min, add 250 parts of a copolymer of di...

Embodiment 2

[0056] A kind of preparation method of water-in-water type colorful paint, comprises the following steps:

[0057] 1. Preparation of colloidal solution: set the stirring speed to 900r / min, add 100 parts of water and 2 parts of sodium pyrophosphate into the mixing container under stirring, after the sodium pyrophosphate is completely dissolved, add 8 parts of lithium magnesium silicate powder, Stir for 120min;

[0058] 2. Preparation of granulated base paint: Add 450 parts of water and 220 parts of styrene-acrylic emulsion into another mixing container, set the stirring speed to 800r / min, add 10 parts of trisodium phosphate, 9 parts of defoamer, 8 parts of film-forming agent, 15 parts of propylene glycol, 10 parts of cellulose, stir for 30 minutes; set the stirring speed at 1000r / min, add 20 parts of composite titanium yellow and 10 parts of cobalt green and stir for 30 minutes; set the stirring speed at 400r / min, Add 300 parts of a copolymer of divinylbenzene and 1-vinylimida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com