Salt-storage epoxy/polyurethane composite coating material for highway and preparation method thereof

A coating material, polyurethane technology, applied in polyurea/polyurethane coatings, epoxy resin coatings, asphalt coatings, etc., can solve the problems of lack of snow melting effect, affecting the road performance of the mixture, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

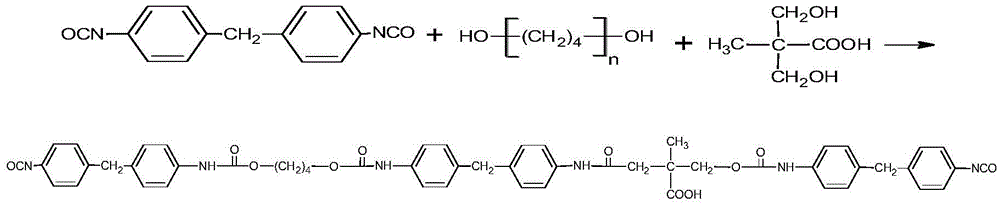

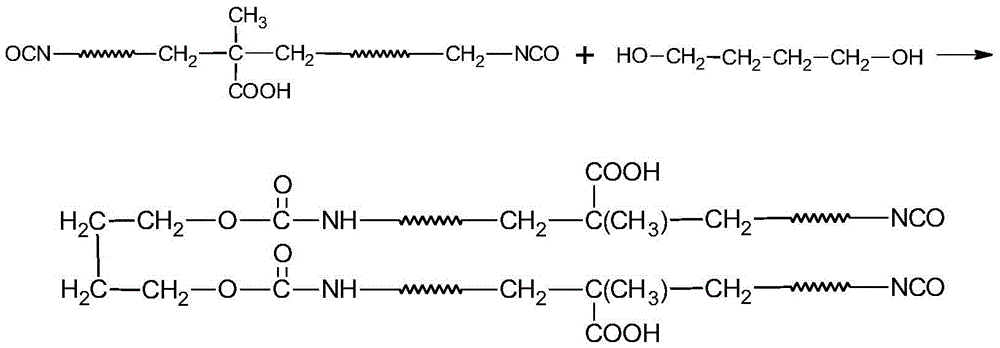

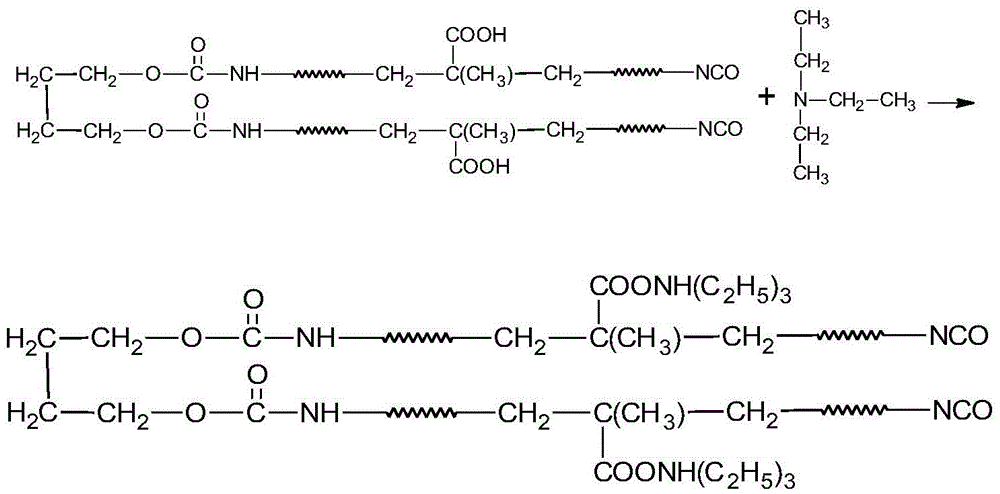

Method used

Image

Examples

Embodiment 1

[0053] A salt-storage epoxy / polyurethane composite coating material for roads described in this embodiment is composed of the following component A, component B and component C measured in parts by mass;

[0054] The A component is 100 parts of non-ionic water-based epoxy resin emulsion with a solid content of 50% and an epoxy value of 0.23mol / 100g;

[0055] The B component is: 80 parts of water-based epoxy resin curing agent with 50% solid content and 0.22mol / 100g amine value, 114 parts of water-based polyurethane, 10 parts of cationic emulsified petroleum asphalt with 50% solid content, rutile titanium 3 parts of white powder, 0.3 part of defoamer, 0.2 part of leveling agent, and 92.5 parts of industrial water; the defoamer is BYK-019 water-based defoamer from BYK, Germany. Described leveling agent is BYK-300 water-based leveling agent of German BYK company.

[0056] The C component includes: 5 parts of magnesium nitrate, 5 parts of ammonium nitrate, 5 parts of potassium ac...

specific Embodiment 2

[0070] A salt-storage epoxy / polyurethane composite coating material for roads described in this embodiment is composed of the following component A, component B and component C measured in parts by mass;

[0071] The A component is 100 parts of non-ionic water-based epoxy resin emulsion with a solid content of 52% and an epoxy value of 0.25mol / 100g;

[0072] The B component is: 90 parts of water-based epoxy resin curing agent with a solid content of 52% and an amine value of 0.24mol / 100g, 72 parts of water-based polyurethane, 20 parts of cationic emulsified petroleum pitch with a solid content of 52%, rutile titanium 7 parts of white powder, 0.8 part of defoamer, 0.5 part of leveling agent, and 109.7 parts of industrial water; the defoamer is DC-71 water-based defoamer from Air Products Company of the United States. Described leveling agent is BYK-300 water-based leveling agent of German BYK company.

[0073] The C component is: 5 parts of magnesium nitrate, 5 parts of ammoni...

specific Embodiment 3

[0088] A salt-storage epoxy / polyurethane composite coating material for roads described in this embodiment is composed of the following component A, component B and component C measured in parts by mass;

[0089] The A component is 100 parts of non-ionic water-based epoxy resin emulsion with a solid content of 51% and an epoxy value of 0.24mol / 100g;

[0090] The B component is: 82 parts of water-based epoxy resin curing agent with a solid content of 51% and an amine value of 0.23mol / 100g, 105 parts of water-based polyurethane, 12 parts of cationic emulsified petroleum pitch with a solid content of 51%, rutile titanium 4 parts of white powder, 0.4 part of defoamer, 0.3 part of leveling agent, and 96.3 parts of industrial water; the defoamer is Tech-365W water-based defoamer from Shanghai Tiger Polymer Technology Co., Ltd. Described leveling agent is the DC-57 water-based leveling agent of American Air Products Company.

[0091] The C component is: 7 parts of potassium nitrate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com