Preparation method of colored raw lacquer

A raw lacquer and color technology, applied in the field of raw lacquer, can solve the problems of low production efficiency of colored raw lacquer, achieve the effects of improving transparency and coloring, high process efficiency, and shortening refining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

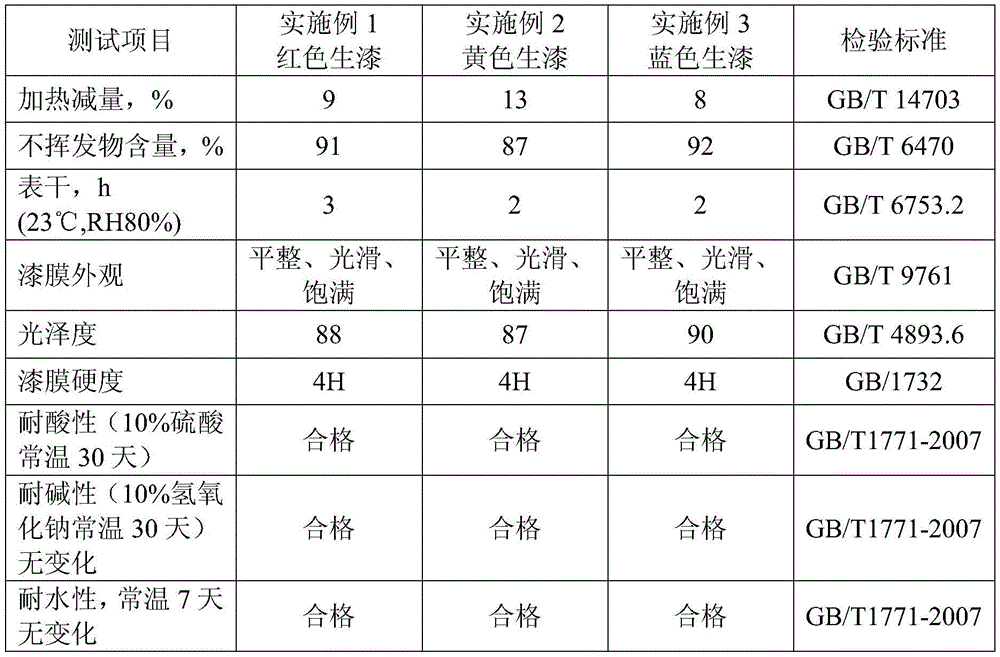

Examples

Embodiment 1

[0028] The present embodiment provides a kind of preparation method of colored raw lacquer, and this method specifically comprises the following steps:

[0029] Step 1: After filtering the raw lacquer to remove impurities, add it to the reaction kettle, gradually raise the temperature to 35°C, add white rot fungus laccase (mass ratio: raw lacquer:white rot fungus laccase=100:5) into the reaction kettle, slowly Introduce oxygen and stir for 7 hours to obtain refined lacquer microemulsion;

[0030] Step two, add hypophosphorous acid (mass ratio is, raw lacquer: hypophosphorous acid=100:1) in the refined microemulsion of raw lacquer gained in step one, continue to stir at 40 ℃, until solid content reaches 95%, add tung oil (mass ratio For, raw lacquer: tung oil=100:10), can get transparent raw lacquer;

[0031] Step 3, adding vermilion powder to cooked tung oil (mass ratio: vermilion powder: cooked tung oil=1:1), high-speed dispersion and grinding for 2 hours, red micron-scale c...

Embodiment 2

[0036] The present embodiment provides a kind of preparation method of colored raw lacquer, and this method specifically comprises the following steps:

[0037] Step 1: After filtering the raw lacquer to remove impurities, add it to the reaction kettle, gradually raise the temperature to 50°C, add white rot fungus laccase (mass ratio: raw lacquer:white rot fungus laccase=100:5) into the reaction kettle, slowly Introduce oxygen and stir for 7.5 hours to obtain refined lacquer microemulsion;

[0038] Step 2, add phosphite (mass ratio is, raw lacquer: phosphite=100:1) to the refined microemulsion of raw lacquer obtained in step 1, continue stirring at 50°C until the solid content reaches 92%, add tung oil ( Mass ratio is, raw lacquer: tung oil=100:10), can get transparent raw lacquer;

[0039] Step 3, adding Fast Yellow to polymerized linseed oil (mass ratio: Fast Yellow: Polymerized Linseed Oil = 1:1), high-speed dispersion and grinding for 1 hour, yellow micron-scale color pas...

Embodiment 3

[0044] The present embodiment provides a kind of preparation method of colored raw lacquer, and this method specifically comprises the following steps:

[0045] Step 1: After filtering the raw lacquer to remove impurities, add it to the reaction kettle, gradually heat up to 30° C., add Aspergillus oryzae laccase (mass ratio is, raw lacquer: Aspergillus oryzae laccase=100:5) into the reaction kettle, slowly Introduce oxygen and stir for 10 hours to obtain refined lacquer microemulsion;

[0046] Step two, add hypophosphorous acid (mass ratio is, raw lacquer: hypophosphorous acid=100:1) to the refined microemulsion of raw lacquer obtained in step one, continue stirring at 30°C until the solid content reaches 97%, add linseed oil (mass Raw lacquer: linseed oil=100:10), linseed oil can also be replaced by catalpa oil to get transparent lacquer;

[0047] Step 3, adding phthalocyanine blue to cooked tung oil (mass ratio: phthalocyanine blue: cooked tung oil = 1:1), high-speed disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com