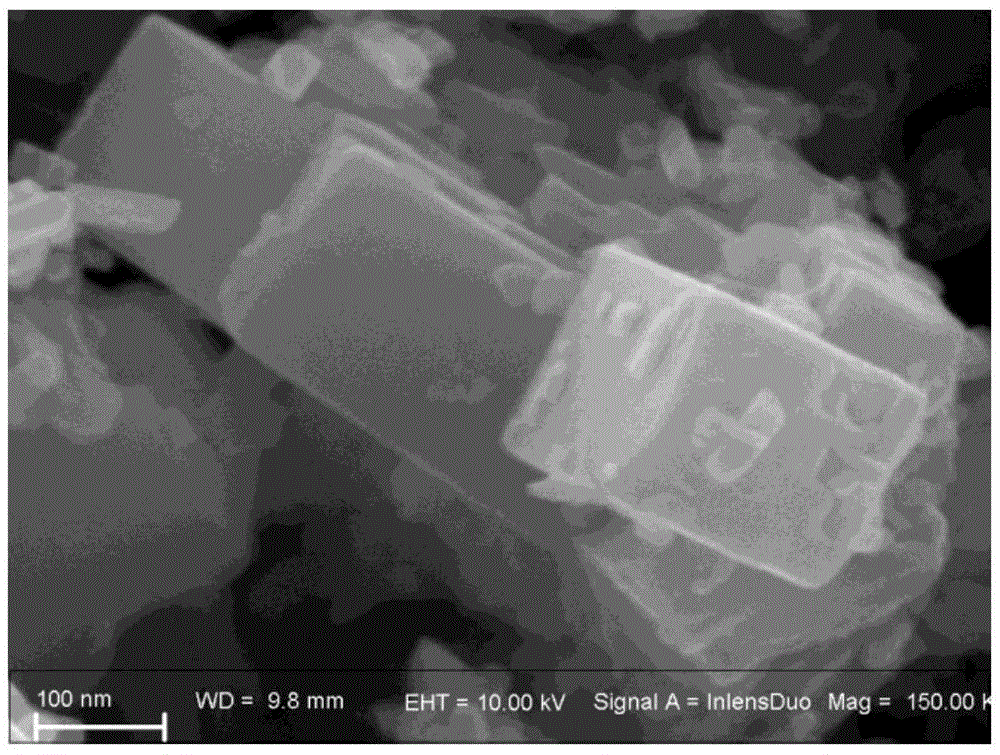

Method for preparing nitrogen oxide sensor element based on tungsten oxide nanometer blocks

A sensor element, nitrogen oxide technology, applied in the field of gas sensor, can solve the problem of high working temperature, and achieve the effect of high gas sensitivity, excellent repeatability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

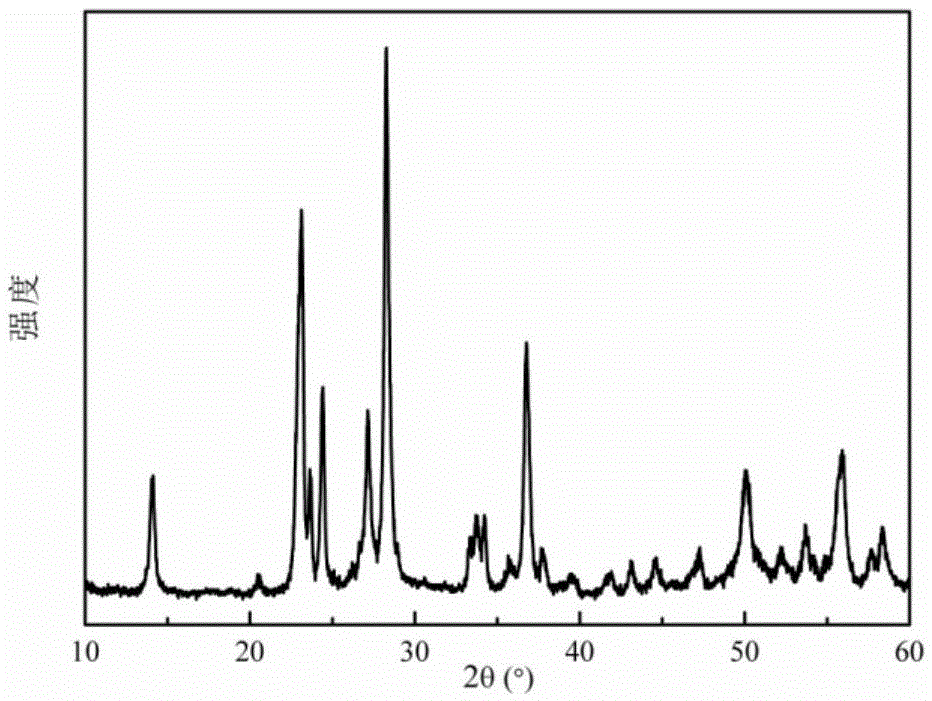

Method used

Image

Examples

Embodiment 1

[0027] (1) Cleaning of the ceramic substrate:

[0028] A ceramic sheet (1 cm × 2 cm) was used as the substrate, and the ceramic sheet substrate was placed in acetone solvent and absolute ethanol for 15 min and ultrasonically oscillated for 15 min to remove surface organic impurities. and dried in an infrared oven.

[0029] (2) Preparation of Pt interdigitated electrodes:

[0030] The ceramic substrate is placed in the vacuum chamber of the DPS-Ⅲ type high-vacuum target magnetron sputtering equipment, using platinum with a mass purity of 99.99% as the target material, and argon gas with a mass purity of 99.999% as the working gas, sputtering The working pressure is 2.0Pa, the sputtering power is 85W, the sputtering time is 10min, the substrate temperature is room temperature, and interdigitated platinum electrodes are formed on the surface of the alumina substrate.

[0031] (3) Prepare reaction solution:

[0032] First prepare a 0.05M tungsten hexachloride solution, weigh 1....

Embodiment 2

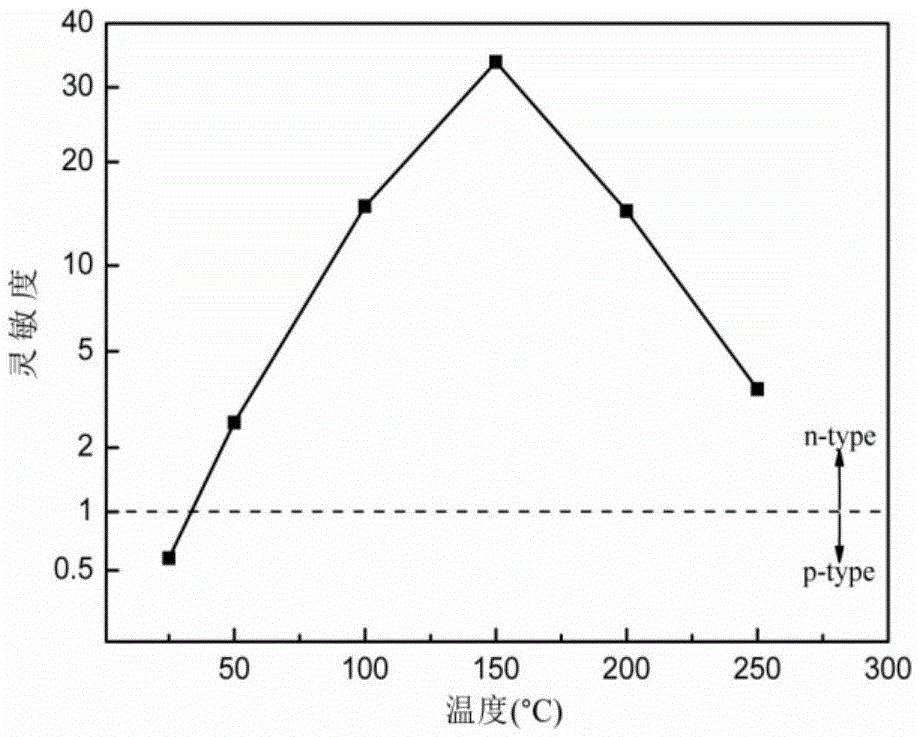

[0045] The difference between this embodiment and Embodiment 1 is that: the concentration of tungsten hexachloride in the solvothermal reaction liquid configured in step (3) is 0.025M, and the gas sensor element of the prepared tungsten oxide nano-block structure is at 100 lppmNO at ℃ 2 The sensitivity for gas is 9.72.

Embodiment 3

[0047]The difference between this embodiment and Example 1 is: the concentration of tungsten hexachloride in the solvothermal reaction liquid configured in step (3) is 0.075M, and the gas sensor element of the prepared tungsten oxide nano-block structure is at 100 lppmNO at ℃ 2 Gas has a sensitivity of 18.34.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com