Multilayer composite film dressing and preparation method thereof

A multi-layer composite film and film layer technology, applied in the field of composite film, can solve problems such as singleness, functional limitations, non-complementary functions or simultaneous existence, etc., to achieve simple operation steps, easy to master the operation process, considerable potential applications and commercial value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 (polyurethane cast film+gelatin nanofiber film):

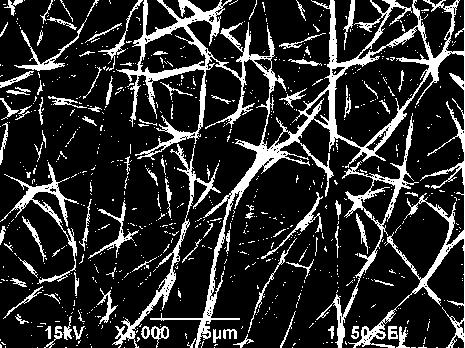

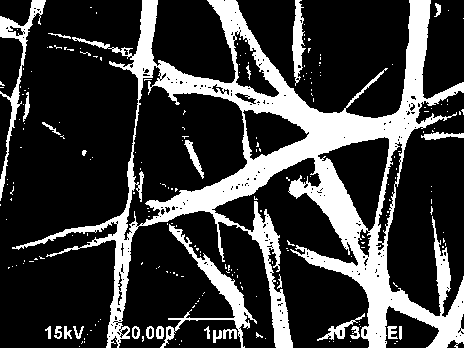

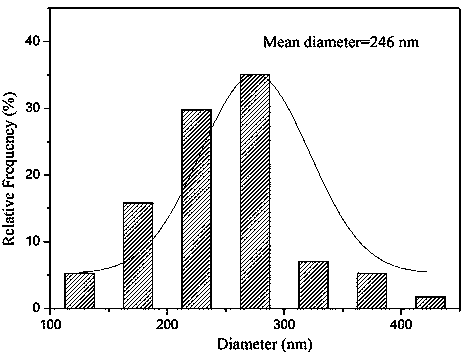

[0033] Weigh 0.78g of polyurethane with a molecular weight of 200,000, and 0.078g of amoxicillin, and dissolve them together in 8.5g of dimethylformamide solvent, and then form a film of 10*10cm. Afterwards, 1.0 g of gelatin with a molecular weight of 30,000 and a Bloom value of 200 was weighed, dissolved in 5 g of formic acid solvent, and fibers were collected on the polyurethane film by electrospinning technology. The electrospinning parameters were: voltage of 15 kv, nozzle and collecting plate The distance is 10cm, the rotation speed of the collecting plate is 10rpm, the flow rate is 2ml / h, the temperature is 22±2°C, and the humidity is 35±3%. Finally, the environment is naturally dry.

Embodiment 2

[0034] Embodiment 2 (polyurethane nanofiber membrane+gelatin nanofiber membrane):

[0035]Weigh 1.0 g of polyurethane with a molecular weight of 100,000 and 0.1 g of ampicillin, and dissolve them together in 10 g of dimethylformamide solvent. The obtained homogeneous solution is used to prepare polyurethane thin nanofiber membranes by electrospinning technology. The electrospinning parameters are: The voltage is 10kv, the distance between the nozzle and the collecting plate is 15cm, the rotation speed of the collecting plate is 100rpm, the flow rate is 1ml / h, the temperature is 30±2°C, and the humidity is 30±2%. Afterwards, 0.8g of gelatin with a molecular weight of 50,000 and a Bloom value of 300 was weighed, dissolved in 6g of water, and continuously electrospun directly on the above-mentioned polyurethane thin nanofiber membrane. 20cm, collection plate rotation speed 20rpm, flow rate 1ml / h, temperature 30±2°C, humidity 30±2%, the obtained gelatin nanofiber membrane was cros...

Embodiment 3

[0036] Embodiment 3 (polyurethane nanofiber film+gelatin casting film):

[0037] Weigh 1.2g of polyurethane with a molecular weight of 150,000, and 0.06g of silver nitrate, and dissolve them together in 20g of dimethylacetamide solvent. The obtained homogeneous solution is used to prepare polyurethane thin nanofiber membranes by electrospinning technology. The electrospinning parameters are: The voltage is 15kv, the distance between the nozzle and the collecting plate is 15cm, the rotation speed of the collecting plate is 50rpm, the flow rate is 4ml / h, the temperature is 28±2℃, and the humidity is 40±3%. Afterwards, 0.6 g of gelatin with a molecular weight of 50,000 and a Bloom value of 100 was weighed, dissolved in 10 g of water, and a 10*10 cm film was formed directly on the polyurethane thin nanofiber membrane by casting method, and then crosslinked with glutaraldehyde for 12 hours. Finally, the environment is naturally dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com