Boron nitride-coated carbon nanotube, and preparation method and application thereof

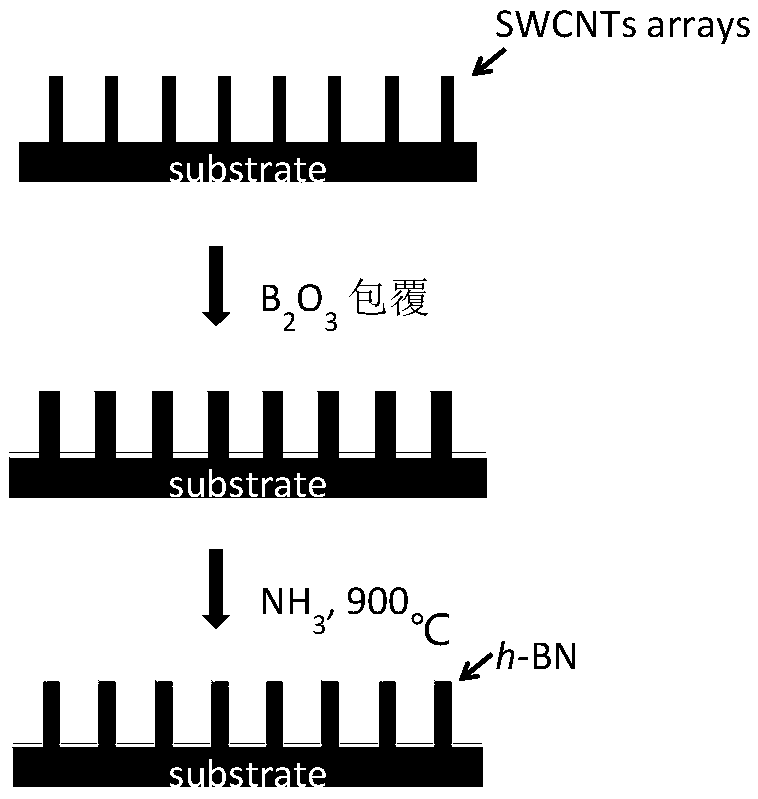

A carbon nanotube, boron nitride package technology, used in carbon nanotubes, chemical instruments and methods, nanotechnology for materials and surface science, etc. Application and popularization, reduction of turn-on field strength, etc., to achieve the effect of increasing field emission current density, field emission performance improvement and improvement, and reducing turn-on field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

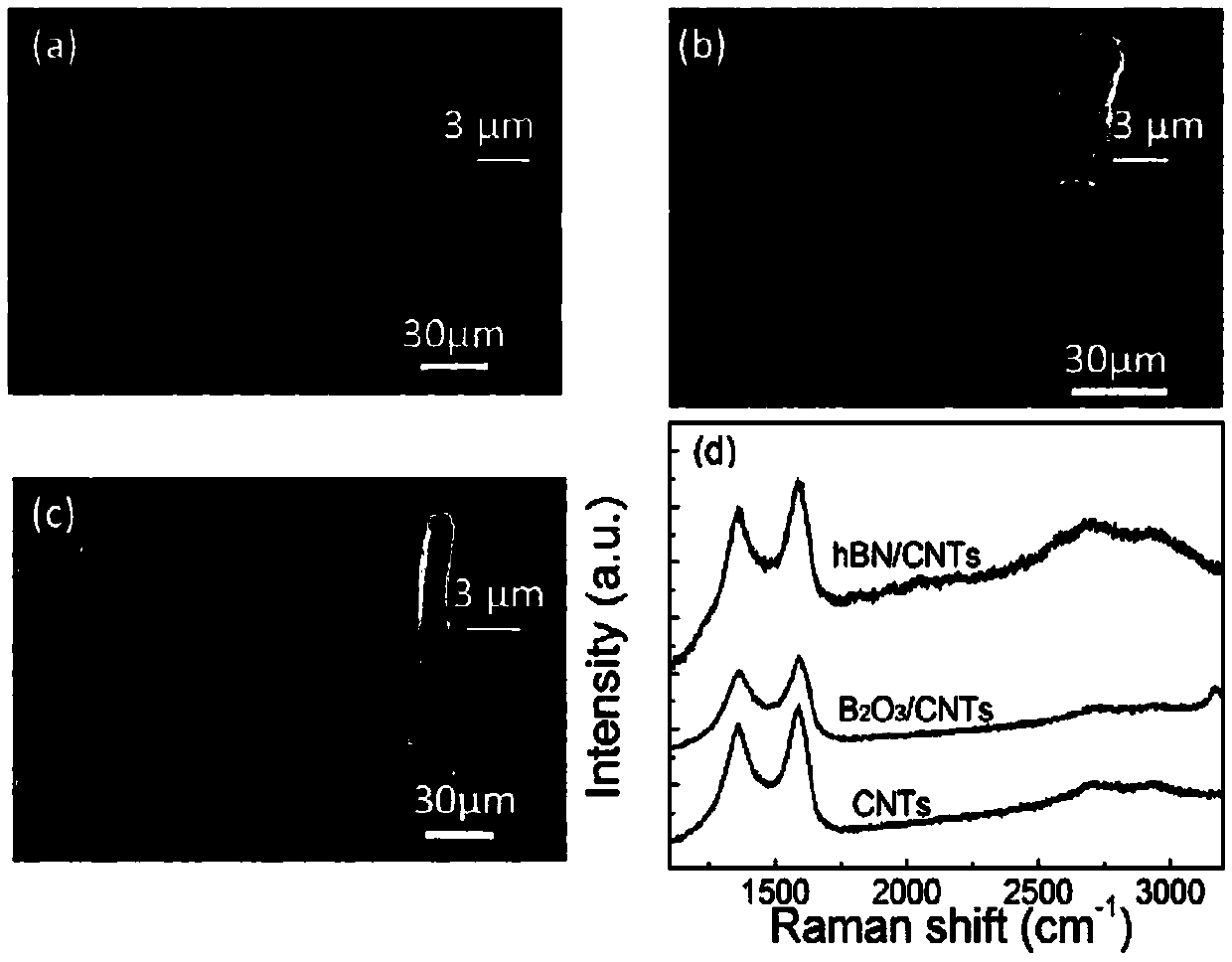

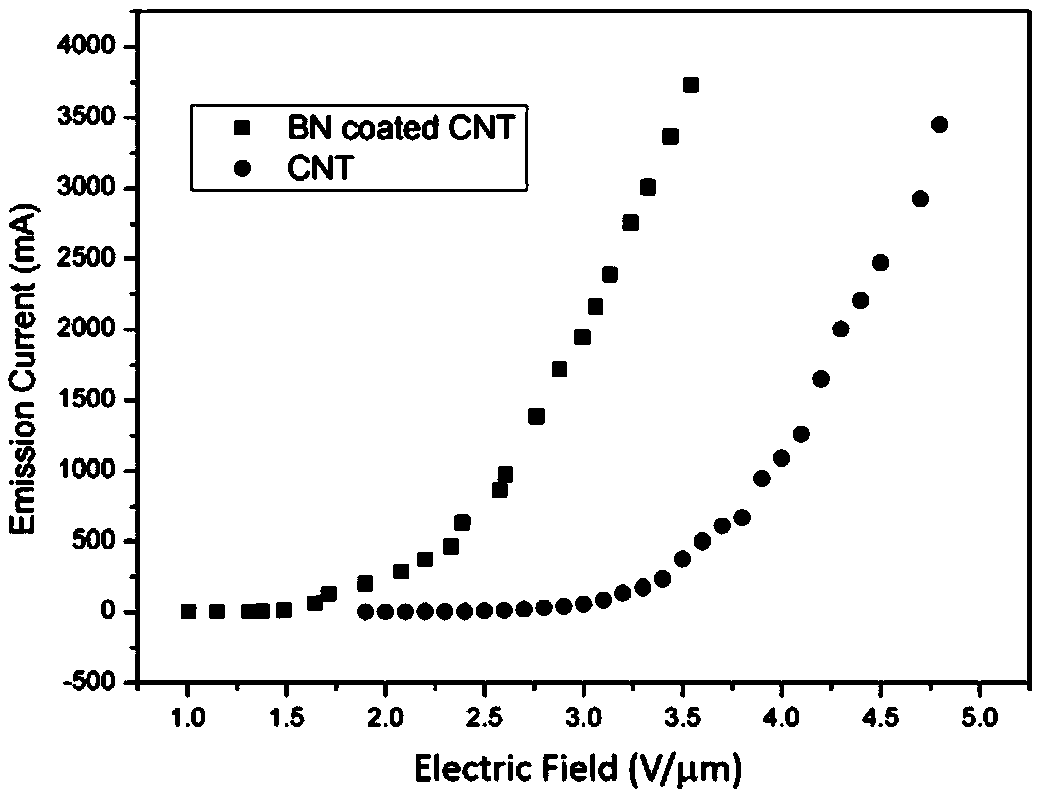

[0047] A carbon nanotube coated with boron nitride, which is coated with a layer of boron nitride with controllable thickness on the outer surface of the carbon nanotube, the thickness of the boron nitride is 3-5nm, and its field emission performance is 92.5mA / cm 2 ; The carbon nanotubes are array-like samples mainly composed of double-walled carbon nanotubes.

Embodiment 2

[0049] A carbon nanotube coated with boron nitride, which is coated with a layer of boron nitride with controllable thickness on the outer surface of the carbon nanotube, the thickness of the boron nitride is 8-10nm, and its field emission performance is 60.0mA / cm 2 ; The carbon nanotube is an array-like sample with a wall thickness of 3-5 layers.

Embodiment 3

[0051] A carbon nanotube coated with boron nitride, which is coated with a layer of boron nitride with controllable thickness on the outer surface of the carbon nanotube, the thickness of the boron nitride is 20-30nm, and its field emission performance is 30.0mA / cm 2 ; The carbon nanotubes are a carbon nanotube array with a wall thickness of more than 10 layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com