Method for large-scale preparation of mesoporous silica

A large-scale preparation technology of mesoporous silica, applied in the direction of silica, silicon oxide, chemical instruments and methods, etc., can solve the problems of no literature and patent reports on mesoporous silica, and achieve large industrialization potential , low price, concentrated pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Including the following steps:

[0040] 1. According to the mass ratio of the sodium-containing additive to the F-class fly ash is 0.3, weigh the fly ash and the sodium-containing additive;

[0041] 2. The fly ash mixed with the ball mill and the sodium-containing additives are baked at a temperature of 1100°C, kept for 30 minutes, taken out, and cooled to room temperature;

[0042] 3. After roasting, mix the material with 5% hydrochloric acid and react at a temperature of 95°C for 60 minutes;

[0043] 4. After the reaction, the solid-liquid mixture is separated by filtration, and the solid powder obtained by filtration is dried at a temperature of 60°C;

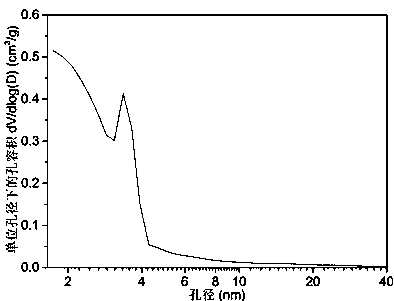

[0044] 5. Nitrogen isothermal adsorption / desorption test was carried out on the prepared mesoporous silica, and the pore size distribution curve was obtained as follows: figure 1 shown.

Embodiment 2

[0046] Including the following steps:

[0047] 1. According to the mass ratio of the calcium-containing additive to the F-class fly ash of 0.5, weigh the fly ash and the calcium-containing additive;

[0048] 2. Put the mixed fly ash and calcium-containing additives into the ball mill for roasting at 1350°C, keep it warm for 120 minutes, take it out, and cool to room temperature;

[0049] 3. After roasting, mix the material with 30% hydrochloric acid and react at a temperature of 20°C for 10 minutes;

[0050] 4. After the reaction is finished, the solid-liquid mixture is separated by filtration, and the solid powder obtained by filtration is dried at a temperature of 200°C;

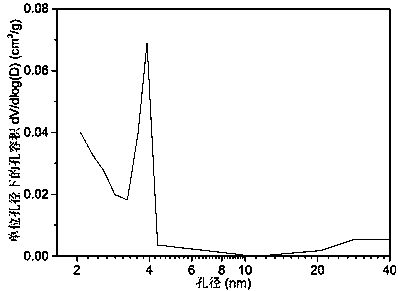

[0051] 5. Nitrogen isothermal adsorption / desorption test was carried out on the prepared mesoporous silica, and the pore size distribution curve was obtained as follows: figure 2 shown.

Embodiment 3

[0053] 1. According to the mass ratio of calcium-containing additives and F-class fly ash is 0.3, weigh fly ash and calcium-containing additives;

[0054] 2. The fly ash and sodium-containing additives mixed by the ball mill are roasted at a temperature of 1100°C, kept for 120 minutes, taken out, and cooled to room temperature;

[0055] 3. After roasting, mix the material with 30% hydrochloric acid and react at a temperature of 95°C for 60 minutes;

[0056] 4. After the reaction is finished, the solid-liquid mixture is separated by filtration, and the solid powder obtained by filtration is dried at a temperature of 200°C;

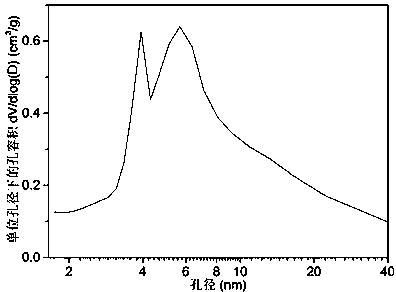

[0057] 5. Nitrogen isothermal adsorption / desorption test was carried out on the prepared mesoporous silica, and the pore size distribution curve was obtained as follows: image 3 shown.

[0058] The technical effect brought by the mesoporous silica material prepared by the present invention is:

[0059] (1) It can effectively solve the problem of fly ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com