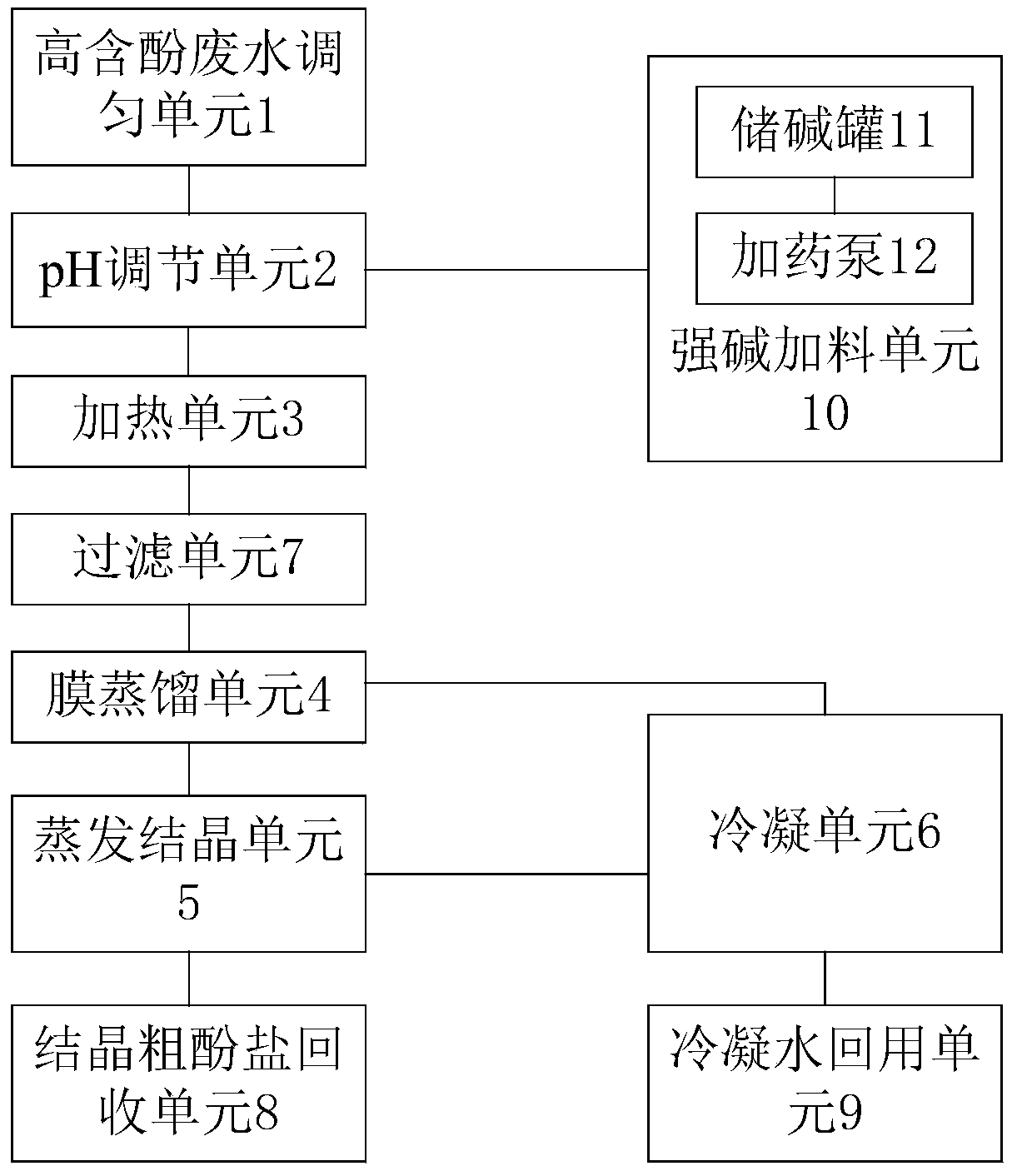

Method and system for treating wastewater with high phenol content

A treatment method and a treatment system technology, which are applied in the field of treatment methods and systems for high-phenol-containing wastewater, can solve problems such as large footprint, secondary pollution, and microbial toxicity, and achieve small footprint, reliable operation, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] A method for treating high phenolic waste water, comprising the steps of:

[0054]S1. In production, the water quality of high phenolic wastewater fluctuates to a certain extent. In order to ensure the stability of the continuous operation of the system, high phenolic wastewater is usually collected in the wastewater storage tank and mixed thoroughly with a mixer.

[0055] S2, adding NaOH to the high-phenol-containing wastewater, adjusting the pH value to 9-12, converting phenolic compounds into phenoxides, and obtaining phenoxide-containing wastewater. Phenyl salts are more stable in wastewater, and are less likely to enter water vapor during membrane distillation and evaporative crystallization.

[0056] S3, heating the phenate-containing wastewater in S2 to 50-70° C. to obtain preheated wastewater. This temperature mainly takes into account the water vapor content and the temperature resistance of the distillation membrane (increasing the water vapor content of wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com