A kind of method utilizing composting reactor to produce high nitrate concentration organic fertilizer

A composting reactor and nitrate technology are applied in the preparation of organic fertilizers, organic fertilizers, organic fertilizer equipment and other directions, which can solve the problems of low nitrate content, no nitrate generation, and failure to occur smoothly, and achieve high nitrogen content. , reducing the large loss of nitrogen, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 composting method of the present invention

[0030] 1. Raw materials

[0031] Cow dung, with a water content of 80% and a C / N ratio of 18, comes from a dairy farm near Shuangliu County.

[0032] 2. Composting method

[0033] 2.1 Raw material pretreatment

[0034] Take cow dung and squeeze it to make the water content 70-72%.

[0035] 2.2 Composting

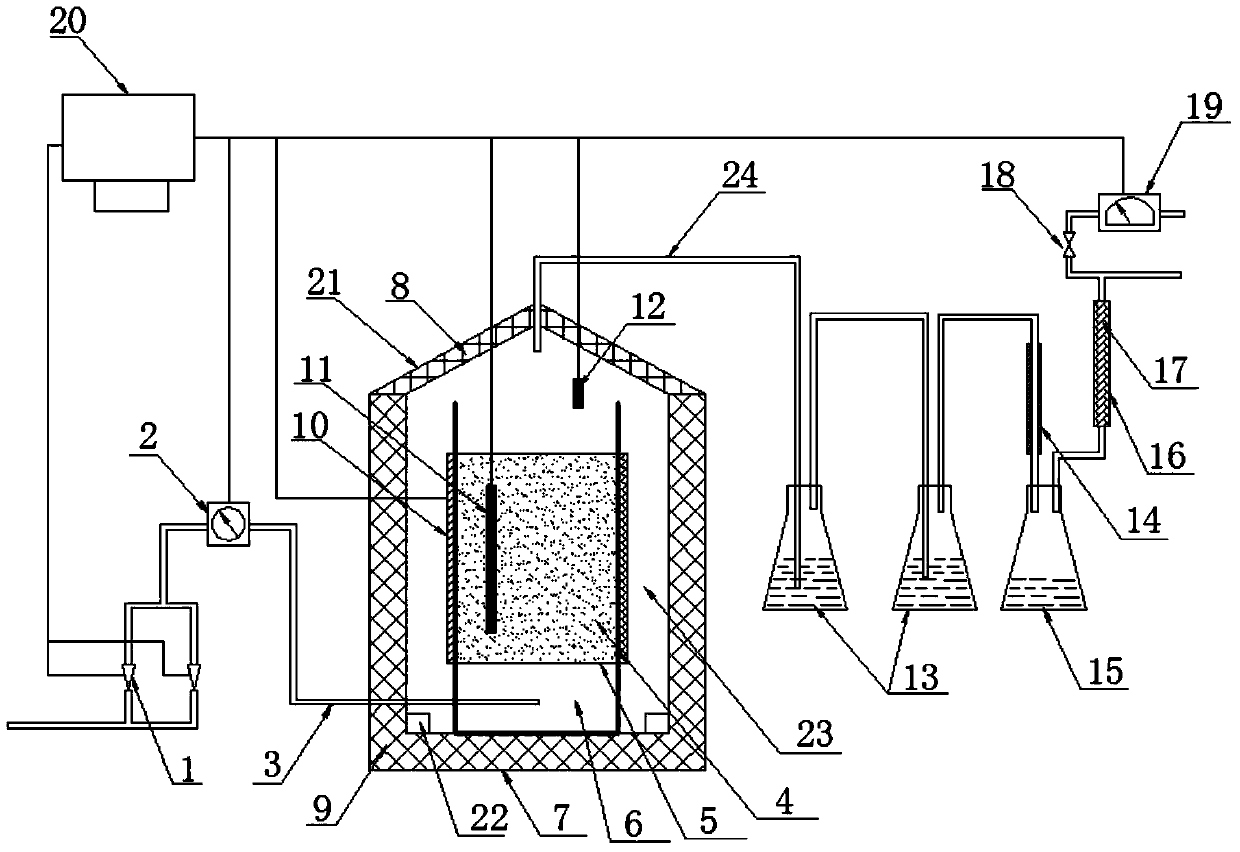

[0036] Composting devices such as figure 1 As shown, it includes a thermal insulation shell 21, a composting chamber 4 and a controller 20. The thermal insulation shell 21 includes a shell 7 and a shell cover 8. The shell cover 8 is covered on the top of the shell 7, and the inner surface of the shell cover 8 is gradually downward from the middle to the edge. Inclined, the housing 7 and the shell cover 8 are double-layer structures, there is a gap between the two layers, and the gap is filled with thermal insulation foam 9; A cavity A23 is formed between them, a heating belt 10 is arranged on the outer wa...

Embodiment 2

[0055] Embodiment 2 composting method of the present invention

[0056] 1. Raw materials

[0057] Chicken manure, with a water content of 78.2% and a C / N ratio of 7.5, came from a laying hen farm near Shuangliu County.

[0058] 2. Composting method

[0059] 2.1 Raw material pretreatment

[0060] Take the chicken manure and squeeze it to make the water content 70-72%.

[0061] 2.2 Composting

[0062] Composting device is the same as embodiment 1.

[0063] Operation mode:

[0064] (1) Feeding: Get the pretreated material and put it into the reactor, the amount of input is 80% of the volume of the reactor.

[0065] (2) Composting process:

[0066] First-stage fermentation: After feeding, the temperature of the composting chamber gradually rises to 60°C (set the heating rate at 0.5°C / hour, and heat with a heating belt when the heating rate is lower than 0.5°C / hour). (The gas introduced is air) is 0.4L / min / kg-dry weight; maintain the temperature in the composting chamber (6...

Embodiment 3

[0079] Embodiment 3 composting method of the present invention

[0080] 1. Raw materials

[0081] The anaerobic digestion sludge of food waste, with a water content of 77.8% and a C / N ratio of 10.5, came from Shuangliu County Airport Food Waste Resource Utilization Company. Sawdust moisture content 11.9%, C / N ratio 343.2, from a wood processing factory around Shuangliu County; mature compost, moisture content 24.6%, C / N ratio 15.3, purchased from the market.

[0082] 2. Composting method

[0083] 2.1 Raw material pretreatment

[0084] Take kitchen waste anaerobic digestion sludge, sawdust and mature compost, mix according to wet weight 10:1:1, the moisture content of the mixture is 65%, and the C / N ratio is 12.2.

[0085] 2.2 Composting

[0086] Composting device is the same as embodiment 1.

[0087] Operation mode:

[0088] (1) Feeding: Get the pretreated material and put it into the reactor, the amount of input is 75% of the volume of the reactor.

[0089] (2) Compost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com