A kind of preparation method of environment-friendly, high-efficiency vulcanization crosslinking agent 1,6-bis(n,n-dibenzylcarbamoyldithio)hexane

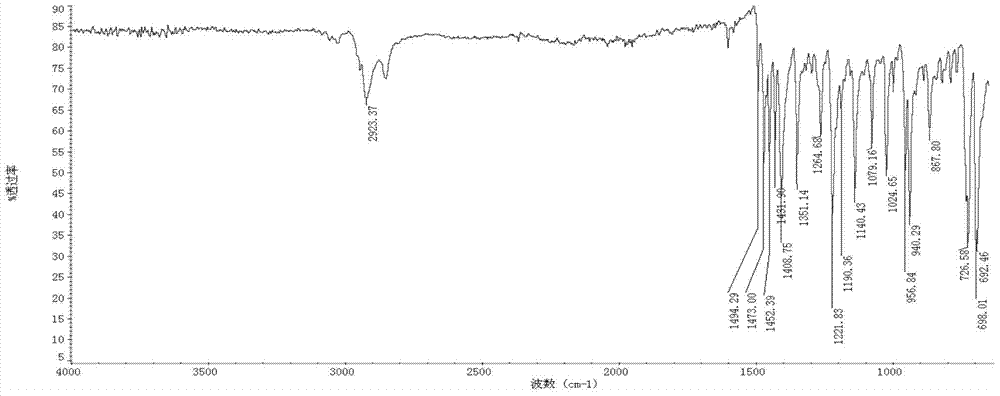

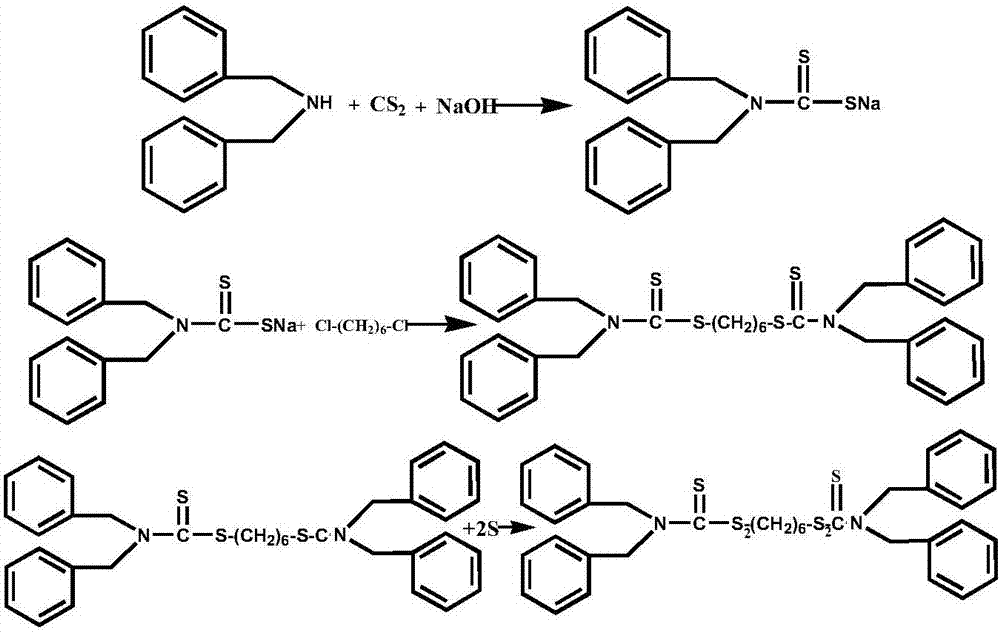

A technology of dibenzylcarbamoyl disulfide and dibenzylcarbamoyl, which is applied in the field of synthesis of rubber additives, can solve the problems of difficult metathesis reaction, unpleasant and toxic smell, slow reaction speed, etc., and achieve high purity, The effect of high yield and easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of environment-friendly, efficient vulcanization cross-linking agent 1,6-bis(N,N-dibenzylcarbamoyldithio)hexane, the steps are as follows:

[0029] (1) Put 39.4g of dibenzylamine, 8.4g of sodium hydroxide and 190g of ethanol into a 1000mL three-neck flask, stir at 20°C for 20min, weigh 16g of carbon disulfide in a constant pressure dropping funnel, and add carbon disulfide dropwise to the flask within 30min. In the three-necked flask, stirring was continued at 20°C for 3 hours, and an ethanol solution containing sodium dibenzyl dithiocarbamate was obtained after the reaction was completed.

[0030] (2) Weigh 14.7g of 1,6-dichlorohexane and 0.2g of KI into the flask, connect the condenser, heat up the system to reflux with a heating mantle, stir for 4 hours under reflux, and cool down to room temperature after the reaction , suction filtration to obtain a white filter cake, put the filter cake into a 500mL beaker, add about 150g of water, sti...

Embodiment 2

[0033] A kind of preparation method of environment-friendly, high-efficiency vulcanization cross-linking agent 1,6-bis(N,N-dibenzylcarbamoyldithio)hexane, the same as Example 1, the difference is:

[0034] Step (1) The reaction temperature is 30° C. to obtain an ethanol solution containing sodium dibenzyl dithiocarbamate.

[0035] Step (2) The filter cake was dried to obtain 60.5 g of white solid 1,6-bis(N,N-dibenzylcarbamoyl-thio)hexane with a total yield of 91%.

[0036] Step (3) obtains 27.4 g of 1,6-di(N,N-dibenzylcarbamoyldithio)hexane product with a content of 97%, and the yield is 94%. The melting point of the final product is 90° C., and the ash content (750°C / 2h) is 0.1%.

Embodiment 3

[0038] A kind of preparation method of environment-friendly, high-efficiency vulcanization cross-linking agent 1,6-bis(N,N-dibenzylcarbamoyldithio)hexane, the same as Example 1, the difference is:

[0039] Step (1) The reaction temperature is 10° C. to obtain an ethanol solution containing sodium dibenzyl dithiocarbamate.

[0040] Step (2) The filter cake was dried to obtain 60 g of white solid 1,6-bis(N,N-dibenzylcarbamoyl-thio)hexane with a total yield of 90.2%.

[0041] Step (3) obtains 27.5 g of 1,6-di(N,N-dibenzylcarbamoyldithio)hexane product with a content of 97%, and the yield is 94.3%. The melting point of the final product is 90° C., and the ash content (750°C / 2h) is 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com