Polyurethane asphalt composite emulsion and use method thereof

A composite emulsion and polyurethane technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of slow curing speed, long surface drying and hard drying time, and reduced construction efficiency of waterborne polyurethane coatings, so as to shorten surface drying time and The effect of hard work time, good comprehensive physical and mechanical properties, and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

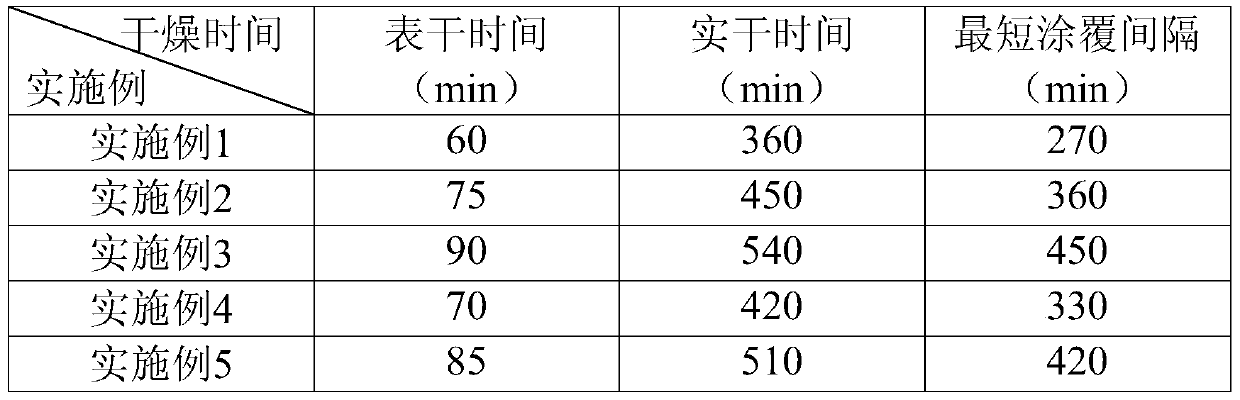

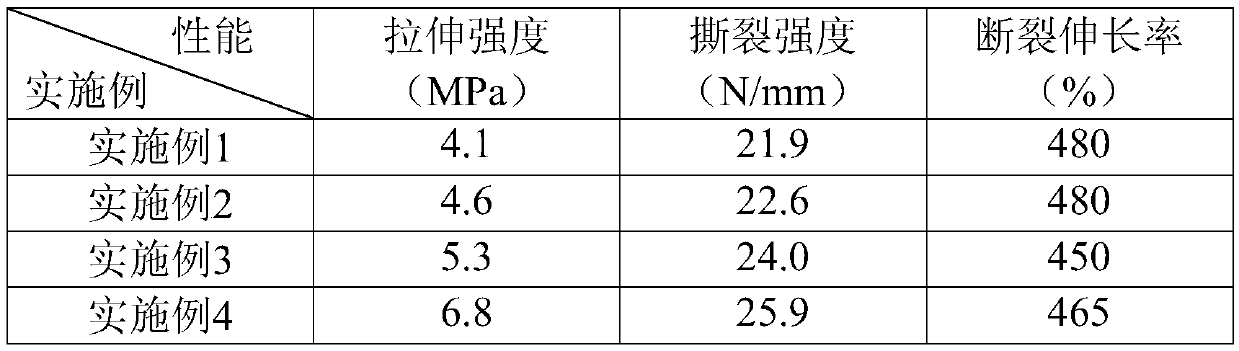

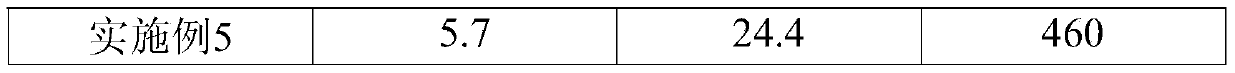

Embodiment 1

[0028] First, prepare component B: mix petroleum asphalt, light calcium carbonate and polyvinyl butyral in proportion, add ethyl caproate, carbodiimide and triethylenediamine at the same time, at a speed of 40r / min Stir for 30 minutes to form a uniform and stable mixed emulsion. The mass fraction of each component in component B is: asphalt 60%; ethyl caproate 10%; carbodiimide 5%; light calcium carbonate 10%; polyvinyl butyral 5%; Ethylenediamine 5%; Water 5%.

[0029] Then carry out the preparation of C component: the mass fraction of tetradecyltrimethylammonium chloride is 60%, and the mass fraction of propanol is 30%.

[0030] Preparation of polyurethane / asphalt composite emulsion before construction: mix component A and component B with a solid content of 40% at a mass ratio of 2:1, and stir at a speed of 20r / min for 15min for spraying.

[0031] Spraying construction: double-gun spraying method is adopted, the spraying amount of component C is 10% of the mass of the com...

Embodiment 2

[0033] First, prepare component B: mix petroleum asphalt, light calcium carbonate and polyvinyl butyral in proportion, add ethyl caproate, carbodiimide and triethylenediamine at the same time, at a speed of 40r / min Stir for 30 minutes to form a uniform and stable mixed emulsion. The mass fraction of each component in component B is: asphalt 50%; ethyl caproate 5%; carbodiimide 5%; light calcium carbonate 15%; polyvinyl butyral 15%; Ethylenediamine 5%; Water 5%.

[0034] Then carry out the preparation of C component: the mass fraction of tetradecyltrimethylammonium chloride is 50%, and the mass fraction of propanol is 25%.

[0035] Preparation of polyurethane / asphalt composite emulsion before construction: Mix A component with a solid content of 40% and B component at a mass ratio of 3:1, and stir at a speed of 20r / min for 15min for spraying.

[0036] Spraying construction: double-gun spraying method is adopted, the spraying amount of component C is 10% of the mass of the com...

Embodiment 3

[0038] First, prepare component B: mix petroleum asphalt, light calcium carbonate and polyvinyl butyral in proportion, add ethyl caproate, carbodiimide and triethylenediamine at the same time, at a speed of 40r / min Stir for 30 minutes to form a uniform and stable mixed emulsion. The mass fraction of each component in component B is: asphalt 55%; ethyl caproate 10%; carbodiimide 10%; light calcium carbonate 10%; polyvinyl butyral 5%; Ethylenediamine 5%; Water 5%.

[0039] Then the preparation of component C was carried out: the mass fraction of tetradecyltrimethylammonium chloride was 40%, and the mass fraction of propanol was 20%.

[0040] Preparation of polyurethane / asphalt composite emulsion before construction: mix component A and component B with a solid content of 40% in a mass ratio of 5:2, and stir at a speed of 20r / min for 15min for spraying.

[0041] Spraying construction: double-gun spraying method is adopted, the spraying amount of component C is 10% of the mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com