Preparation method of elastic hard lubricating nano composite thin-film material

A nano-composite, thin-film material technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as wear and loud noise, and achieve the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

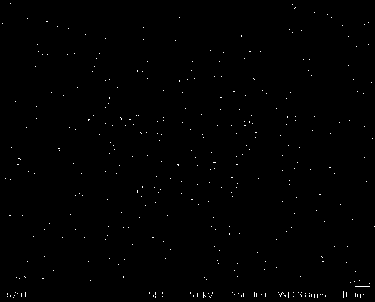

[0026] Deposition: Change the sputtering gas to N 2 and Ar into the chamber to control the total pressure and N 2 The partial pressures were 1.5Pa and 20%, respectively, the incident angle of the deposited ions was 90° to the substrate, the distance between the target and the substrate was 8cm, the deposition time was 60min, the initial chamber temperature was 25°C, and the power of the DC power supply was 1000W. Bias voltage and duty cycle are -200V and 60% respectively, pure titanium target is sputtered, and a series of TiN nano-films can be prepared by changing the incident angle of deposited ions (0-90°). Etching: only the etching gas N 2 Into the chamber, the total pressure is 2.5Pa, the initial chamber temperature is 40°C, the negative bias voltage and duty cycle are -900V and 80% respectively, and the etching time is 40min. Different channels can be prepared by adjusting the etching time Structure and pore size of nanoporous TiN frameworks. Carbon-containing plasma t...

Embodiment 2

[0029] As described in Example 1, the pure titanium target was replaced with a pure chromium target to prepare a series of elastic hard lubricating nanocomposite films with CrN as the skeleton.

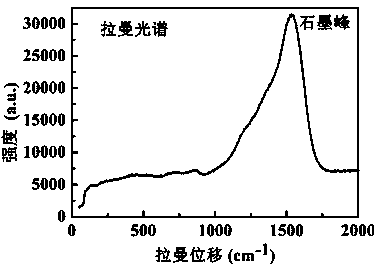

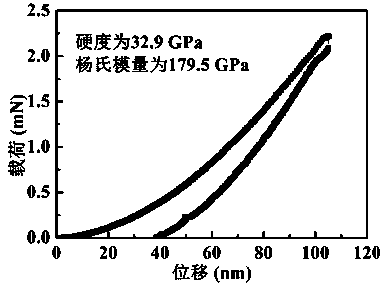

[0030] The CrN skeleton and the nanocomposite film were observed with a field emission scanning electron microscope. The CrN skeleton is a rod-shaped porous structure with a thickness of 500nm, while the film thickness of the nanocomposite film is about 620nm. The thickness of the graphite layer is 120nm. The composite film and the substrate are well bonded, and there is no gap. The application of X-ray diffractometer shows that the elastic hard lubricating nanocomposite film has the crystal phase structure of chromium nitride and chromium carbonitride. In Raman spectroscopy, graphite peaks are clearly present in such nanocomposite films. The surface of the film was found to be relatively smooth with a roughness of less than 5nm by atomic force microscopy. Through the scratch test, ...

Embodiment 3

[0032] As described in Example 1, a series of elastic hard lubricating nanocomposite films with ZrN as the skeleton were prepared by replacing the pure titanium target with the pure zirconium target.

[0033] Using a field emission scanning electron microscope to observe the ZrN skeleton and nanocomposite film, the ZrN skeleton is a rod-shaped porous structure with a thickness of 350nm, while the film thickness of the nanocomposite film is about 450nm, so the thickness of the graphite layer is 100nm. The composite film and the substrate are well bonded, and there is no gap. The application of X-ray diffractometer shows that the elastic hard lubricating nanocomposite film has the crystal phase structure of zirconium nitride and zirconium carbonitride. In Raman spectroscopy, graphite peaks are clearly present in such nanocomposite films. The surface of the film was found to be relatively smooth with a roughness of less than 5nm by atomic force microscopy. Through the scratch t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com