High performance liquid chromatographic method for detecting mass concentration of sodium sulfocyanate in milk and dairy product

A high-performance liquid chromatography, sodium thiocyanate technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of complex treatment methods and impact on recovery rate, and achieve good adsorption effect, good accuracy, and high detection sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Pretreatment steps of milk and dairy products: first add 5ml of acetonitrile to 10ml of milk sample, and precipitate to remove the protein in the milk sample. Then a solid-phase extraction column is used to remove part of the water-soluble vitamins and amino acids in the milk or dairy product sample, and the eluate is collected. The solid-phase extraction column uses basic alumina as a filler. Then the eluate was centrifuged and degreased, and it was ready to be detected by high performance liquid chromatography.

[0029] Determine the chromatographic conditions as follows: mobile phase is 0.2% triethylamine phosphate (pH=7.0): acetonitrile=95: 5, in volume ratio; 0.2% triethylamine sulfate is prepared as follows: first dissolve phosphoric acid in deionized water Prepare a phosphoric acid solution with a mass concentration of 0.2%, and then add triethylamine to the phosphoric acid solution to adjust the pH to 7. Agela-ASBCl8 (250mm×4.6mm, 5μm) chromatographic column; c...

Embodiment 2

[0031] The pretreatment steps of milk and dairy products are the same as in Example 1.

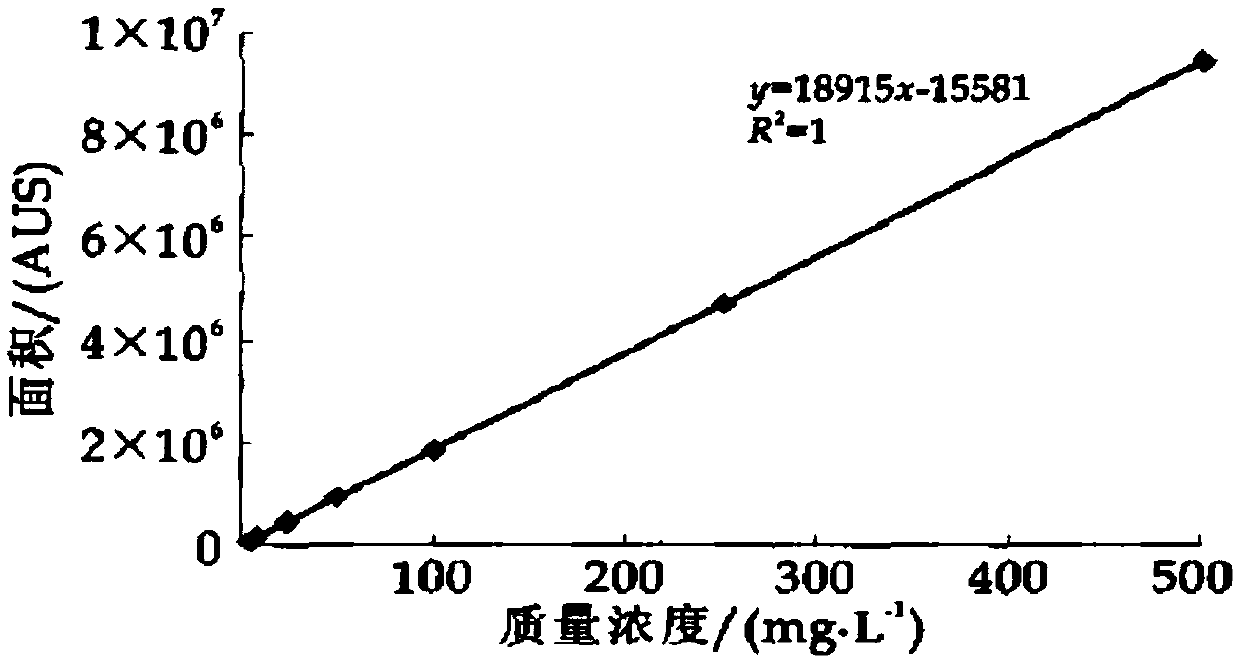

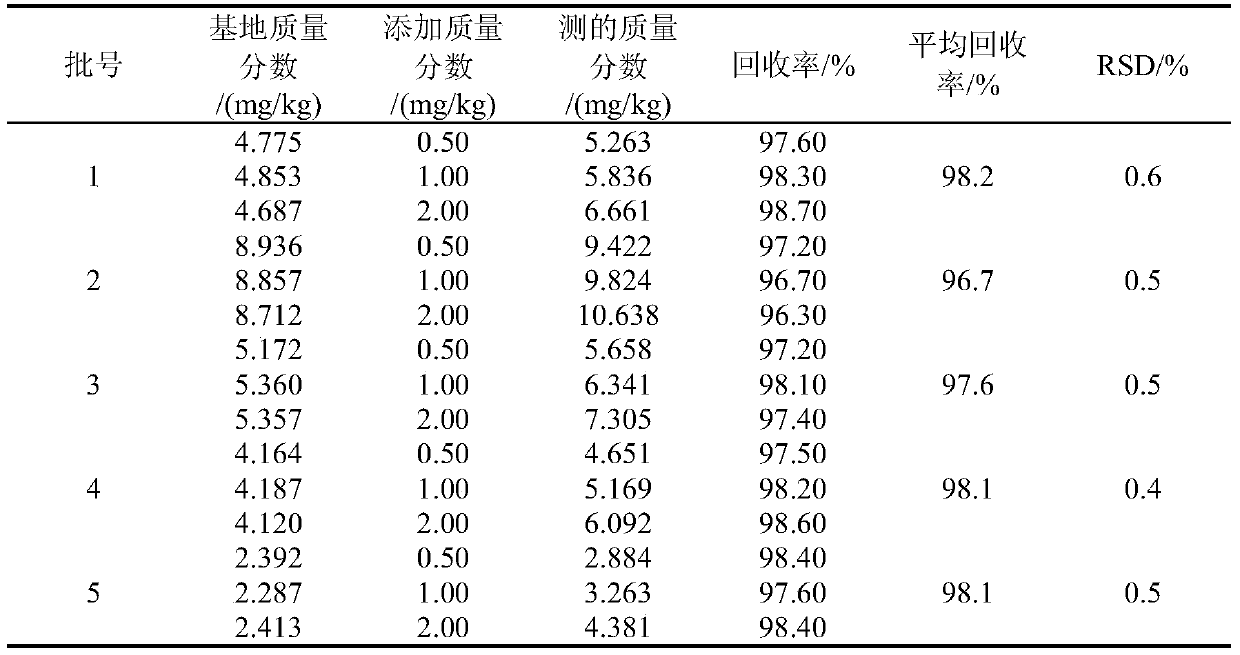

[0032] Determine the chromatographic conditions as follows: mobile phase is 0.2% triethylamine phosphate (pH=7.0): acetonitrile=95: 5, in volume ratio; 0.2% triethylamine sulfate is prepared as follows: first dissolve phosphoric acid in deionized water Prepare a phosphoric acid solution with a mass concentration of 0.2%, and then add triethylamine to the phosphoric acid solution to adjust the pH to 7. Agela-ASBCl8 (250mm×4.6mm, 5μm) chromatographic column; column temperature is 25°C; flow rate is controlled at 0.8mL / min; detection wavelength is 215nm; injection volume is 9μL. Under the above chromatographic conditions, the system suitability test was carried out on the blank, standard working solution and sample solution. The theoretical plate of sodium thiocyanate was 7623, the separation between the main peak and the impurity peak was greater than 2.0, and the tailing factor was 1.25. A...

Embodiment 3

[0034] The pretreatment steps of milk and dairy products are the same as in Example 1.

[0035] Determine that the chromatographic conditions are: mobile phase is 0.2% triethylamine phosphate (pH=7.0): acetonitrile=95: 5; Agela-ASBCl8 (250mm * 4.6mm, 5 μ m) chromatographic column; Column temperature is 30 ℃; Flow velocity is controlled at 0.8mL / min; the detection wavelength is 218nm; the injection volume is 10μL. Under the above chromatographic conditions, the system suitability test was carried out on the blank, standard working solution and sample solution. The theoretical plate of sodium thiocyanate was 7623, the separation between the main peak and the impurity peak was greater than 2.0, and the tailing factor was 1.25. According to the calculation of 3 times the signal-to-noise ratio, the detection limit can be 1 mg / L, and the 10-fold signal-to-noise ratio can be used to calculate the limit of quantification to be 3.3 mg / L. The detection limit can reach 0.2 mg / kg; the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com