Method for removing SO2 and NOX from flue gas of coal-fired boiler by virtue of phosphoric ore pulp and phosphorus sludge

A technology for coal-fired boilers and phosphate rock slurry, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems that nitrogen and sulfur cannot be effectively used, and achieve the effects of saving preparation processes, causing large pollution, and promoting transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

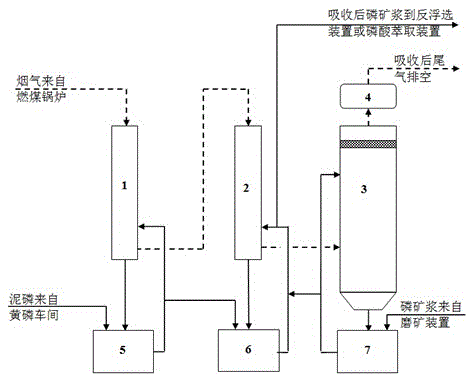

[0028] Such as figure 1 As shown, the coal-fired boiler containing SO 2 2000mg / m 3 , NO x 200mg / m 3 The flue gas enters the power wave oxidation tower 1 from top to bottom, and oxidizes the liquid at a temperature of 50°C (water turbid liquid containing mud phosphorus, and the mud phosphorus from the yellow phosphorus workshop passes through the primary circulation tank 5 and then passes into the oxidation tower) Countercurrent contact, control the elemental phosphorus content in the oxidation solution to 5g / L, the gas velocity to 35m / s, and the liquid-to-gas ratio to 7L / m 3 , in the oxidation tower, most of NO is oxidized to NO which is easily soluble in water 2 , and then enter the first-level absorption tower 2 (empty tower) with three layers of nozzles. In the first-level absorption tower 2, the flue gas is in countercurrent contact with the phosphate slurry from bottom to top (the phosphate slurry comes from the grinding workshop of the phosphate chemical plant area ...

Embodiment 2

[0031] Such as figure 1 As shown, the coal-fired boiler containing SO 2 3000mg / m 3 , NO x 300mg / m 3 The flue gas enters the power wave oxidation tower 1 from top to bottom, and contacts with the oxidizing liquid (water turbid liquid containing mud phosphorus) at a temperature of 60°C countercurrently. The content of elemental phosphorus in the oxidizing liquid is controlled to 10g / L, and the gas velocity is 35m / s, liquid-gas ratio 7L / m 3 , in the oxidation tower, most of NO is oxidized to NO which is easily soluble in water 2 , and then enter the kinetic wave primary absorption tower 2 with a layer of nozzles. In the primary absorption tower 2, the flue gas is in countercurrent contact with the phosphate slurry from the secondary absorption tower 3 from top to bottom (phosphorus The solid content of pulp is controlled at 40%, pH=6), 60%~70% SO 2 , NO x It is absorbed in the primary absorption tower 2, and the rest enters the secondary absorption tower 3 (empty tower wi...

Embodiment 3

[0034] Containing SO from coal-fired boilers 2 6000mg / m 3 , NO x 500mg / m 3 The flue gas enters the dynamic wave oxidation tower from top to bottom, and contacts with the oxidizing liquid (mixed slurry containing mud phosphorus and phosphate slurry) at a temperature of 70°C countercurrently. The content of elemental phosphorus in the oxidizing liquid is controlled to 15g / L, and the gas velocity is 20m / s, liquid-gas ratio 7L / m 3 , in the oxidation tower, most of NO is oxidized to NO which is easily soluble in water 2 , and then enter the kinetic wave primary absorption tower with 2 layers of nozzles. In the primary absorption tower, the flue gas is in countercurrent contact with the phosphate slurry from the secondary absorption tower 3 from top to bottom (phosphate slurry Solid content is controlled at 35%, pH=5.5), 70% to 80% SO 2 , NO x It is absorbed in the first-level absorption tower, and the rest enters the second-level absorption tower (empty tower with 2 layers o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com