Adsorbent and preparation method

A technology of adsorbent and waste catalyst, which is applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of weak adsorption capacity, complicated process, low stability, etc., and achieve reduction of treatment cost, treatment The effect of simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

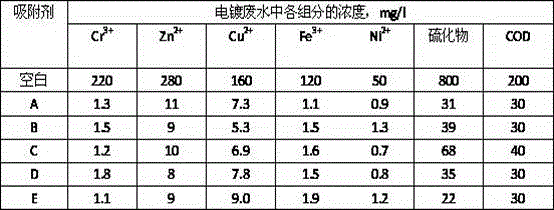

Image

Examples

Embodiment 1

[0024] (1) Add 30.6g of FCC waste catalyst, 14.4g of sepiolite, 11.0 of diatomite and 30ml of water to make a slurry, add 7.5g of aluminum chloride, adjust the final pH value of the slurry to 3.0 with hydrochloric acid, heat to 65°C, and react for 3h , filter, get filter material;

[0025] (2) Add 59.3g of kaolin to 20ml of water to make a slurry, add 90g of potassium acetate solution with a mass concentration of 50% dropwise for 1.0h, then adjust the pH of the system to 9.0 with sodium hydroxide, raise the temperature to 100°C, and the reaction time 0.5h, the reaction material was obtained;

[0026] (3) Mix the filter material obtained in step (1) with the reaction material obtained in step (2), and roll into a ball to form adsorbent A.

Embodiment 2

[0028] (1) Add 367g of FCC waste catalyst, 257g of bentonite and 630ml of water to make a slurry, add 16.2g of aluminum sulfate, adjust the final pH of the slurry to 4.0 with sulfuric acid, heat to 50°C, react for 12 hours, and filter to obtain a filter material;

[0029] (2) Add 71g of kaolin to 70ml of water to make a slurry, add 120g of ethylene glycol solution dropwise for 1.0 hours, then adjust the pH of the system to 11.0 with sodium silicate, raise the temperature to 50°C, and react for 20 hours to obtain the reaction material ;

[0030] (3) Mix the filter material obtained in step (1) with the reaction material obtained in step (2), and extrude to obtain adsorbent B.

Embodiment 3

[0032] (1) Add 7.6g of FCC waste catalyst, 43.0g of attapulgite and 33ml of water to make a slurry, add 3.2g of aluminum nitrate, adjust the final pH of the slurry to 5.0 with nitric acid, heat to 60°C, react for 6 hours, and filter to obtain material;

[0033] (2) Add 15.4g of kaolin to 11ml of water to make a slurry, add 52.0g of potassium acetate solution with a mass concentration of 50% dropwise for 0.5 hours, then adjust the pH of the system to 9.5 with sodium hydroxide, raise the temperature to 60°C, and the reaction time 15h, get reaction material;

[0034] (3) Mix the filter material obtained in step (1) with the reaction material obtained in step (2), and press into tablets to obtain adsorbent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com