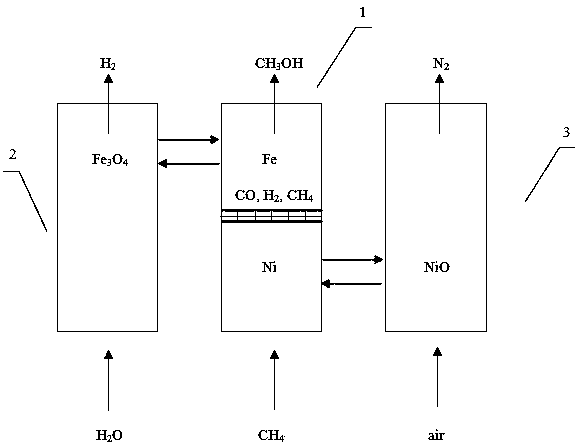

A method and device for simultaneously producing hydrogen and liquid fuel

A liquid fuel and fuel reactor technology, which is applied to chemical instruments and methods, preparation of liquid hydrocarbon mixtures, and hydrogen production, etc. The effect of hydrocarbon selectivity, reduction of carbon deposition, and reasonable heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of catalyst in the embodiment:

[0030] Weigh 40g Fe(NO 3 ) 3 9H 2 O was dissolved in 200mL of distilled water, stirred evenly, 130g of zirconia powder was taken, evaporated to dryness at 50°C with a rotary evaporator, and then o C drying 12h, at 900 o C was roasted for 4h to obtain Fe 2 o 3 / ZrO 2 Oxygen carrier, where Fe 2 o 3 The mass content is 15%.

[0031] Weigh 29g Ni(NO 3 )2 ·6H 2 O was dissolved in 200mL of distilled water, stirred evenly, 130g of silicon oxide was taken, evaporated to dryness at 50°C with a rotary evaporator, and then o C drying 12h, at 900 o C roasting for 4h to obtain NiO / SiO 2 Oxygen carrier, in which the mass content of NiO is 10%.

Embodiment 1

[0033] Place 15gFe in the upper part of the fuel reactor 2 o 3 / ZrO 2 Catalyst, place 25gNiO / SiO in the lower section 2 Catalyst, separated by a screen to allow CO, H 2 and CH 4 pass. The start-up temperature of the lower section of the fuel reactor is 800°C, the upper section has only the heat preservation part and no heating part, and the pressure of the upper section is controlled at 2MPa. The air reactor temperature was controlled at 500°C. The temperature of the hydrogen production reactor is controlled at 750°C. The methane gas flow rate is 100 mL / min, the air flow rate is 50 mL / min, and the water flow rate is 10 mL / min.

Embodiment 2

[0035] Place 15gFe in the upper part of the fuel reactor 2 o 3 / ZrO 2 Catalyst, place 25gNiO / SiO in the lower section 2 Catalyst, separated by a screen to allow CO, H 2 and CH 4 pass. The start-up temperature of the lower section of the fuel reactor is 950°C, the upper section has only the heat preservation part and no heating part, and the pressure of the upper section is controlled at 2MPa. The air reactor temperature was controlled at 500°C. The temperature of the hydrogen production reactor is controlled at 750°C. The methane gas flow rate is 100 mL / min, the air flow rate is 50 mL / min, and the water flow rate is 10 mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com