Process for crushed coal pressurized gasification industrial wastewater deep processing and high recovery rate

A technology for pressurized gasification of crushed coal and industrial wastewater, which is applied in the direction of heating water/sewage treatment, water/sewage treatment, multi-stage water/sewage treatment, etc. High cost and other issues, to achieve the effect of low operating cost, reduced processing costs, and reduced investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

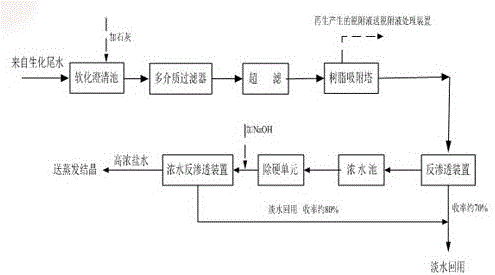

Image

Examples

Embodiment 1

[0046] (1) softening clarifier

[0047] Biochemical tail water (COD: 120mg / L, TDS: 3000mg / L, total hardness: 200mg / L, color 50 times, turbidity: 10, bicarbonate: 112mg / L) enters the lime softening and clarification tank, according to the wastewater Lime is added to the content of bicarbonate in the water according to the molar ratio of 1.1:1, and PAC coagulant is added. The dosage of coagulant is 20mg / L wastewater. The hydraulic retention time of the lime softening clarifier is 2h and the pH is 9. . The bicarbonate of calcium and magnesium ions reacts to form carbonate precipitate, which is removed after clarification. The total hardness removal rate is 55%, and the total hardness is 90mg / L. The softened clarifier effluent enters the multi-media filter.

[0048] (2) Multi-media filter

[0049] The effluent from the softening and clarification tank passes through the multi-media filter, the filter material is anthracite, the working pressure of the filter is 0.35MPa, and the...

Embodiment 2

[0059] (1) softening clarifier

[0060] Biochemical tail water (COD: 150mg / L, TDS: 3600mg / L, total hardness: 400mg / L, color 60 times, turbidity: 15, bicarbonate: 250mg / L) enters the lime softening and clarification tank, according to the wastewater Lime is added to the content of bicarbonate in the water according to the molar ratio of 1.15:1, and PAC coagulant is added. The dosage of coagulant is 23mg / L wastewater. The hydraulic retention time of the lime softening clarifier is 2h and the pH is 9.1 . The bicarbonate of calcium and magnesium ions reacts to form carbonate precipitate, which is removed after clarification. The total hardness of the effluent is 160mg / L, and the total hardness removal rate is 60%. The softened clarifier effluent enters the multi-media filter.

[0061] (2) Multi-media filter

[0062] The effluent from the softening and clarification tank passes through the multi-media filter, the filter material is anthracite, the filtering working pressure is 0...

Embodiment 3

[0072] (1) softening clarifier

[0073] Biochemical tail water (COD: 200mg / L, TDS: 4500mg / L, total hardness: 600mg / L, color 80 times, turbidity: 20, bicarbonate: 420mg / L) enters the lime softening and clarification tank, according to the wastewater Lime is added to the content of bicarbonate in the water according to the molar ratio of 1.2:1, and PAC coagulant is added. The dosage of coagulant is 25mg / L wastewater. The hydraulic retention time of the lime softening clarifier is 2.5h, and the pH is 9.3. The bicarbonate of calcium and magnesium ions reacts to form carbonate precipitate, which is removed after clarification. The total hardness of the effluent is 220mg / L, and the total hardness removal rate is 63%. The softened clarifier effluent enters the multi-media filter.

[0074] (2) Multi-media filter

[0075] The effluent from the softening and clarification tank passes through the multi-media filter, the filter material is anthracite, the working pressure of the filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com