Method for separation and purification of salt during production of 2,4,5-triamino-6-hydroxypyrimidine sulfate

A technology for the production process of hydroxypyrimidine, applied in the field of synthesis of pharmaceutical intermediates, can solve the problems of high cost of hazardous waste treatment, large amount of hazardous waste, expensive one-time investment, etc., to eliminate the amount of hazardous waste generated and reduce the content of waste water Salt content, beneficial effect of biological treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

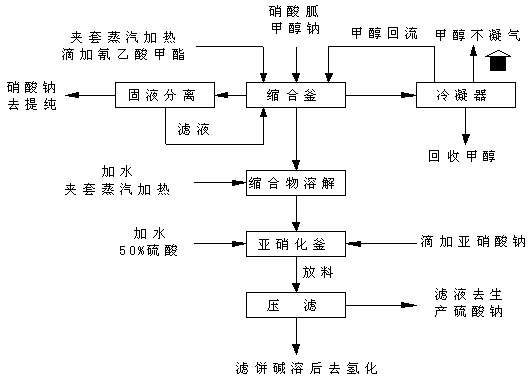

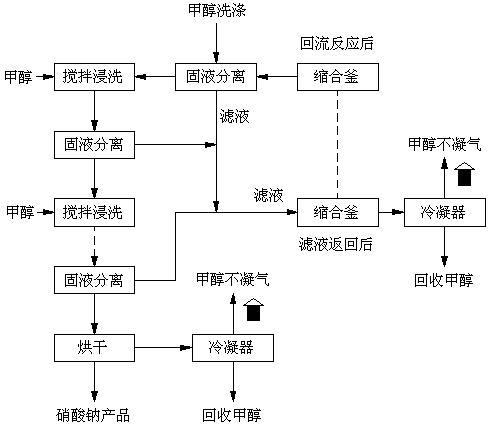

[0023] Put 330kg of guanidine nitrate into the dried 1000L jacketed condensation kettle, and then drop into 480kg of 30% sodium methoxide. See the reflux at one-third of the time, continue to drop without flushing, the dropping time is about half an hour, after the dropping is completed, the materials in the reactor undergo condensation reaction at a temperature of 67-70°C to form the condensate 2.4-diamino -6-Hydroxypyrimidine. After four hours of reflux, feed the material into a closed centrifuge for solid-liquid separation. After the separation, use 150L methanol for centrifugal washing, and pump the filtrate and washing liquid into the condensation kettle; the sodium nitrate filter cake washed with methanol is stirred and soaked with 300L methanol , and then centrifuged, and the methanol solution was collected into the condensation tank. Distill and condense the methanol in the condensation kettle under normal pressure above 65°C. After the methanol is recovered, add 500L...

Embodiment 2

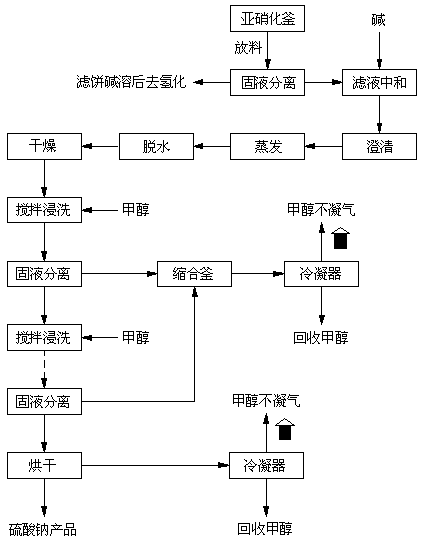

[0025]Add 1100L of water and 300L of 50% sulfuric acid to the 5000L nitrosation kettle where the condensate is added. When the temperature does not exceed 30°C, add 606L of dissolved 30% sodium nitrite dropwise to the nitrosation kettle for 0.5-1 hour After the dropwise addition is completed, after the end point is detected with test paper, keep warm for 1 hour, discharge and press filter to obtain the nitroside 2.4-diamino-5-nitroso-6-hydroxypyrimidine and the press-filtrate. Neutralize the filtrate to neutral with 56L of 30% sodium hydroxide, clarify and remove solid impurities, and obtain crude sodium sulfate by evaporation, drying and dehydration; stir and soak the crude sodium sulfate with 200L of methanol, then perform centrifugation, methanol solution Collected into the condensation tank and the filtrate of Example 1 to distill and condense to recover methanol and distillation residue; dry the sodium sulfate separated by centrifugation, and heat it to above 65°C. Methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com