Antibacterial deodorizing PE (polyethylene) sole material and preparation method thereof

A sole material and anti-oxidant technology, applied in the field of sole materials, can solve the problems of no antibacterial and deodorizing properties, inability to remove odors, and difficult evaporation of sweat, so as to improve antibacterial and deodorizing properties, improve durability, and durability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

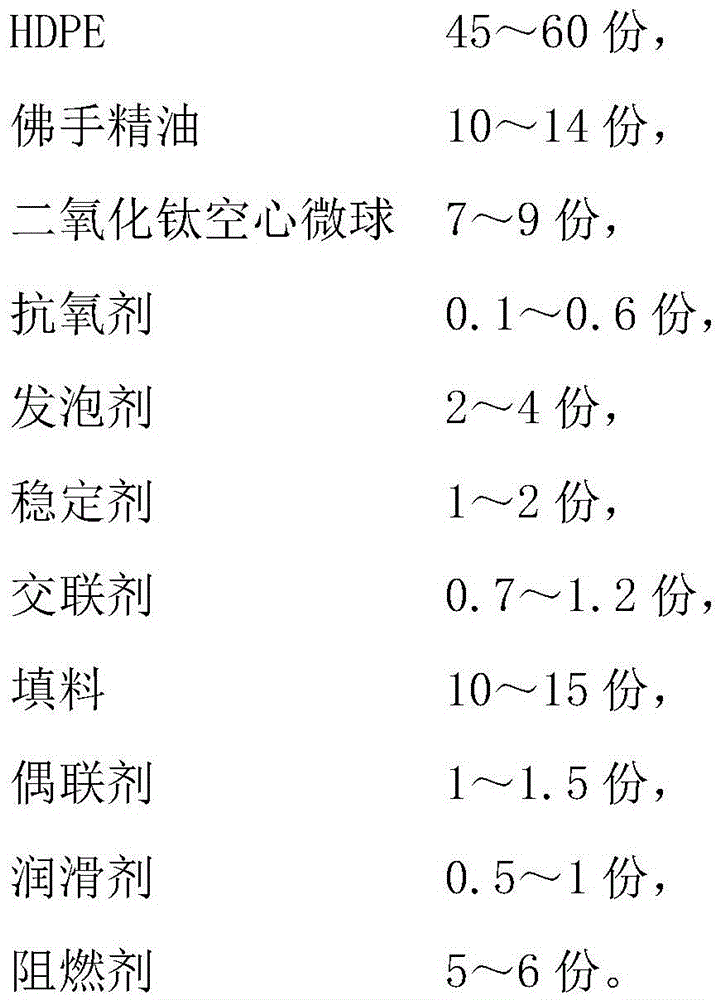

[0026] An antibacterial and deodorant PE shoe sole material, made of the following components by weight: 45 parts of HDPE, 12 parts of bergamot essential oil, 8.5 parts of titanium dioxide hollow microspheres, 10760.5 parts of antioxidant, 2.5 parts of AC, stearic acid 1.8 parts of barium, 1.2 parts of DCP, 14 parts of mica powder, 1.4 parts of silane coupling agent WD-10, 0.6 parts of EBS, 5.5 parts of superfine magnesium hydroxide.

[0027] The steps of its preparation method are as follows:

[0028] (1) Put the bergamot peel into absolute ethanol after being pulverized, the solid-to-liquid ratio of the bergamot peel and absolute ethanol is 1:25g / ml, the power is 155W, the temperature is 45 ℃ under ultrasonic extraction 45 minutes, use without Water sodium sulfate is dried and filtered, and the filtrate is concentrated by rotary evaporation under normal pressure to obtain bergamot essential oil;

[0029] (2) Grind titanium dioxide hollow microspheres and add them to the ber...

Embodiment 2

[0032] An antibacterial and deodorant PE shoe sole material, made of the following components in parts by weight: 55 parts of HDPE, 10.5 parts of bergamot essential oil, 7 parts of titanium dioxide hollow microspheres, 10760.4 parts of antioxidant, 4 parts of AC, 1.5 parts of barium stearate 0.8 parts of DCP, 12 parts of calcium carbonate, 1.2 parts of silane coupling agent WD-10, 0.9 parts of EBS, 5.7 parts of superfine magnesium hydroxide.

[0033] Its preparation method is the same as Example 1.

Embodiment 3

[0035] An antibacterial and deodorizing PE shoe sole material, made of the following components by weight: 50 parts of HDPE, 10 parts of bergamot essential oil, 7.5 parts of titanium dioxide hollow microspheres, 10760.2 parts of antioxidant, 2.4 parts of AC, stearic acid 1.4 parts of barium, 0.7 parts of DCP, 10 parts of mica powder, 101 parts of silane coupling agent WD-101 parts, 0.5 parts of EBS, 5.2 parts of superfine magnesium hydroxide.

[0036] Its preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com