Method for preparing vertical orientation graphene sheet/high polymer thermal interface material

A thermal interface material and vertical orientation technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of improved thermal conductivity, carbon nanotubes can not be well coupled with the matrix, etc., to achieve improved thermal conduction, easy industrial production, The effect of easy flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Here are related experiments based on the existing conditions in the laboratory.

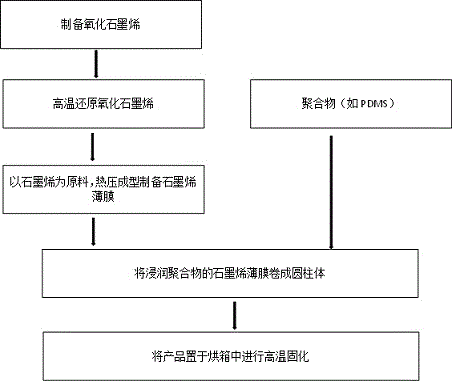

[0018] 1. Preparation of graphene oxide

[0019] Mainly take natural flake graphite as basic raw material, utilize improved Hummers method to prepare graphene oxide, and the operating steps of its preparation are as follows:

[0020] (1) Put 200ml of concentrated sulfuric acid in a conical flask, add 4g of sodium nitrate, put the conical flask in a water bath (add water at room temperature), and stir until the sodium nitrate is completely dissolved in the concentrated sulfuric acid;

[0021] (2) Slowly add 4g of graphite during the stirring process, during which the temperature of the water bath is controlled below 8°C;

[0022] (3) Slowly add 18g of potassium permanganate during stirring, and control the temperature of the water bath below 8°C;

[0023] (4) Seal the Erlenmeyer flask with a sealing film, add an appropriate amount of ice cubes in a water bath to keep the temperature at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com