Rice wine brewing method for reducing content of ethyl carbamate through protocatechuic acid

A technology for urethane and rice wine brewing, applied in the direction of microorganism-based methods, biochemical equipment and methods, and the preparation of alcoholic beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Yellow rice wine brewing method utilizing protocatechuic acid to degrade ethyl carbamate:

[0025] 1. The brewing of rice wine:

[0026] The brewing raw material that the present invention chooses is glutinous rice, brews yellow rice wine.

[0027] Put glutinous rice and water in a ratio of 1:1.2, that is, 0.75kg of glutinous rice, 0.9L of clean water, soak the rice at 28°C for 2 days; after the rice grains are soft, keep the water attached to the rice for cooking; Sprinkle the glutinous rice with water; after the product temperature of the glutinous rice drops to 30°C after the water is poured, put it in a vat and set up a pot, add 0.1% Saccharomyces cerevisiae when it is dropped into the vat, and mix the Saccharomyces cerevisiae powder and glutinous rice thoroughly to form a concave nest.

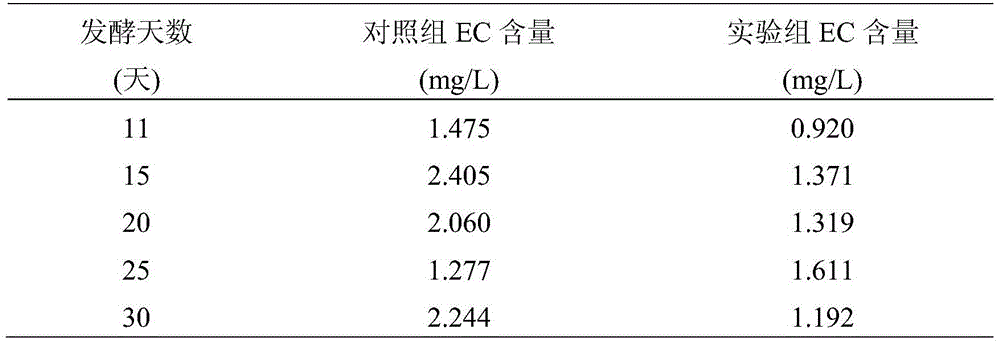

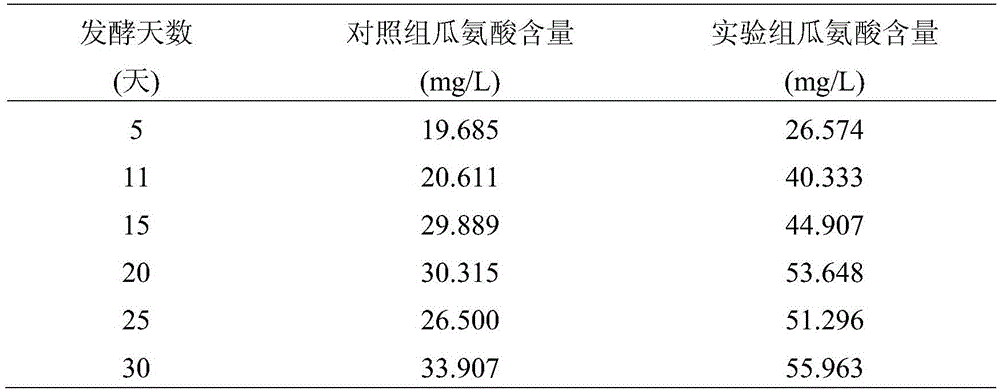

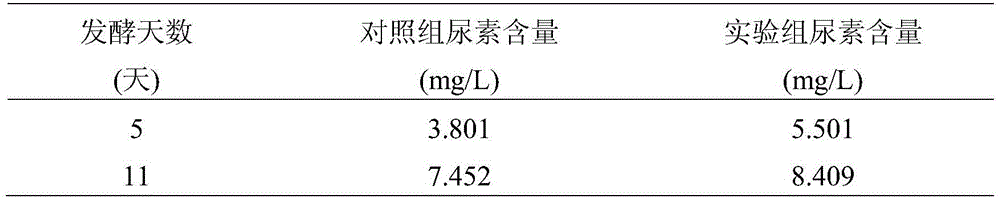

[0028] After raising the nest for 36 hours in the vat, add 5% wheat koji and 0.9L water for fermentation, and add 0.18g protocatechuic acid to make the final concentration 200mg / L...

Embodiment 2

[0061] With reference to the rice wine brewing process of Example 1, in the stage of adding koji and adding water, 0.09 g of protocatechuic acid was added to the fermented liquid to make its concentration 100 mg / L based on the volume of water added, and other conditions were the same as in Example 1.

[0062] The detection method of EC concentration is the same as embodiment 1.

[0063] According to the method of this example, after 30 days of fermentation, it was detected that the concentration of EC in the fermentation broth was 1.70 mg / L.

Embodiment 3

[0065] With reference to the rice wine brewing process of Example 1, in the stage of adding koji and adding water, 0.27g of protocatechuic acid was added to the fermented liquid to make its concentration 300 mg / L based on the volume of water added, and other conditions were the same as in Example 1.

[0066] The detection method of EC concentration is the same as embodiment 1.

[0067] According to the method of this example, the concentration of EC in the fermentation broth detected after 30 days of fermentation was 1.32 mg / L.

[0068] From the results of Examples 1 to 3, it is shown that the EC content in the rice wine brewed by adding protocatechuic acid is lower than that of the naturally fermented control group, and the concentration of protocatechuic acid can inhibit the production of EC when it is 100~300mg / L, and The effect is best when the concentration is 200mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com