High-xylose-tolerance difunctional hemicellulolytic enzyme and encoding gene and preparation method thereof

A hemicellulose and dual-function technology, applied in the field of genetic engineering, can solve the problems of low xylose tolerance and difficulty in meeting industrial needs, and achieve the effects of reducing anti-nutritional effects, increasing fragrance, and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Cloning of gene XylRBM26

[0048] Extract Massiliasp.RBM26 genomic DNA: centrifuge the bacterial liquid cultured in liquid for 2 days to get the thallus, add 1mL lysozyme, treat at 37°C for 1h, then add the lysate, the lysate consists of: 50mM Tris, 20mM EDTA, NaCl500mM, 2% SDS (w / v), pH 8.0, lysed in a water bath at 70°C for 1 hour, mixed every 10 minutes, and centrifuged at 10,000 rpm for 5 minutes at 4°C. The supernatant was extracted in phenol / chloroform to remove impurity proteins, and then an equal volume of isopropanol was added to the supernatant. After standing at room temperature for 5 minutes, centrifuge at 10,000 rpm for 10 minutes at 4°C. The supernatant was discarded, the precipitate was washed twice with 70% ethanol, dried in vacuum, dissolved by adding an appropriate amount of TE, and stored at -20°C for later use.

[0049]5 μg of Massiliasp.RBM26 genome was broken into fragments of 400-600 bp with an ultrasonic breaker Biorupter, and the br...

Embodiment 2

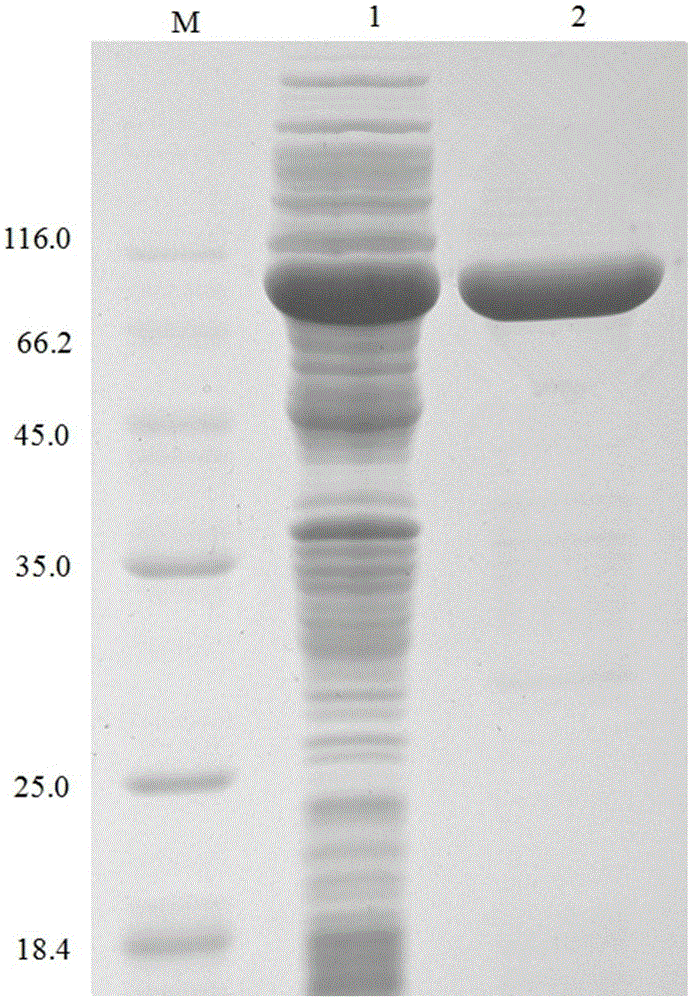

[0051] Example 2: Preparation of recombinant bifunctional hemicellulose degrading enzyme XylRBM26

[0052] According to the sequence analysis results of the bifunctional hemicellulose degrading enzyme gene XylRBM26, the primers for amplifying the mature peptide were designed:

[0053] XylRBM26F: ATGATCCACAACCCGATCCTGC

[0054] XylRBM26R: CAGCCGGCTGAGGTAGGGCC

[0055] Using the genome of strain Massiliasp.RBM26 as a template, the above primers amplify the target gene by PCR. The PCR reaction parameters were pre-denaturation at 94°C for 5 minutes; denaturation at 94°C for 30S, annealing at 72°C for 30S, extension at 72°C for 1min30S, a total of 20 cycles; denaturation at 94°C for 30S, annealing at 52°C for 30S, and extension at 72°C for 1min30S, a total of 10 cycles; After amplification at 72°C, it was extended for 7 minutes; the temperature was decreased by 1°C for each cycle from 72°C to 52°C.

[0056] The bifunctional hemicellulose degrading enzyme gene XylRBM26 and the ex...

Embodiment 3

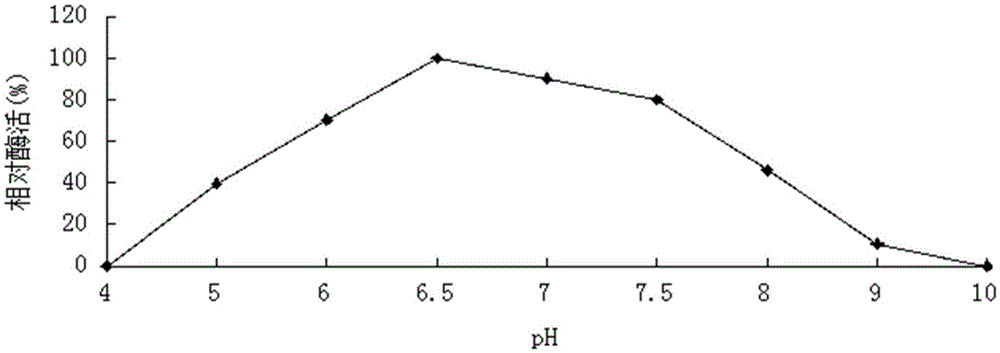

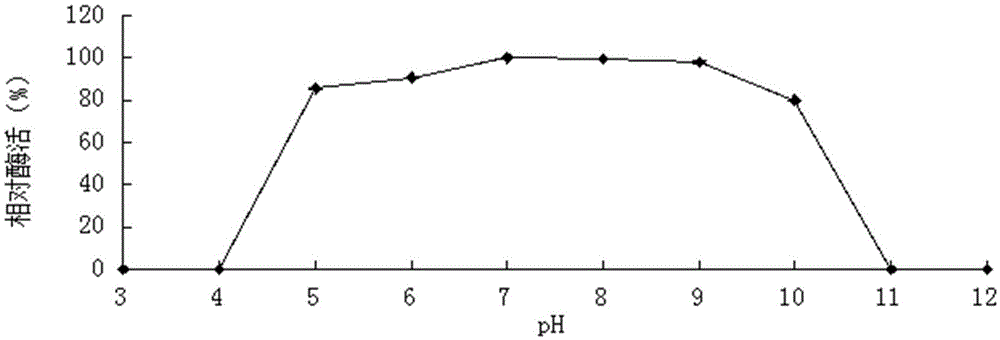

[0058] Example 3 Determination of the properties of the purified recombinant bifunctional hemicellulose degrading enzyme XylRBM26

[0059] 1. Activity analysis of purified recombinant bifunctional hemicellulose degrading enzyme XylRBM26

[0060] The method for measuring the activity of the recombinant bifunctional hemicellulose-degrading enzyme XylRBM26 adopts the pNPX method: pNPX is dissolved in 0.1M buffer to make the final concentration 2mM. 450μL of 2mM substrate; after preheating at the reaction temperature for 5min, add 50μL of an appropriate amount of diluted enzyme solution, and after 10min of reaction, add 2mL of 1M Na 2 CO 3 Terminate the reaction, measure the released pNP at a wavelength of 405nm after cooling to room temperature; 1 enzyme activity unit (U) is defined as the amount of enzyme required to decompose pNPX to produce 1 μmol pNP per minute (the enzyme activity determination method of the pNP substrate is the same as that of pNPX) . 3,5-dinitrosalicyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com