Chemical etching method for bismuth selenide material

A chemical etching and bismuth selenide technology, which is applied in the field of chemical etching of bismuth selenide materials, can solve the problems that the surface of bismuth selenide materials deviates from the stoichiometric ratio, it is difficult to obtain an etching interface, and the etching rate is too fast. , to achieve the effect of convenient etching rate, etching rate control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

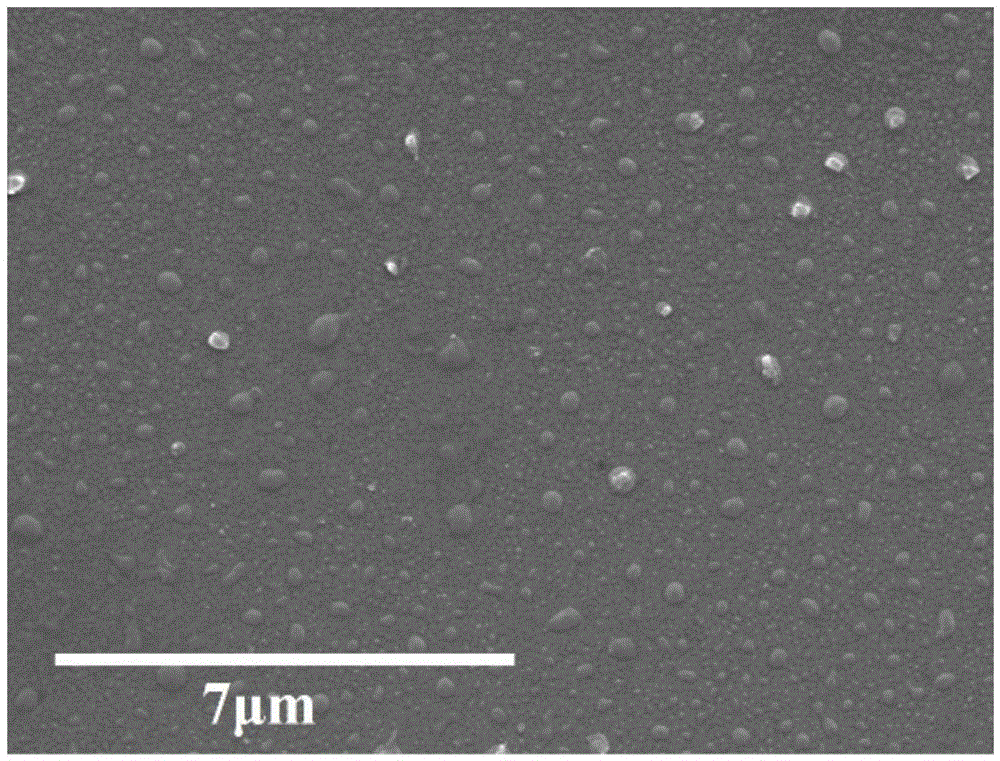

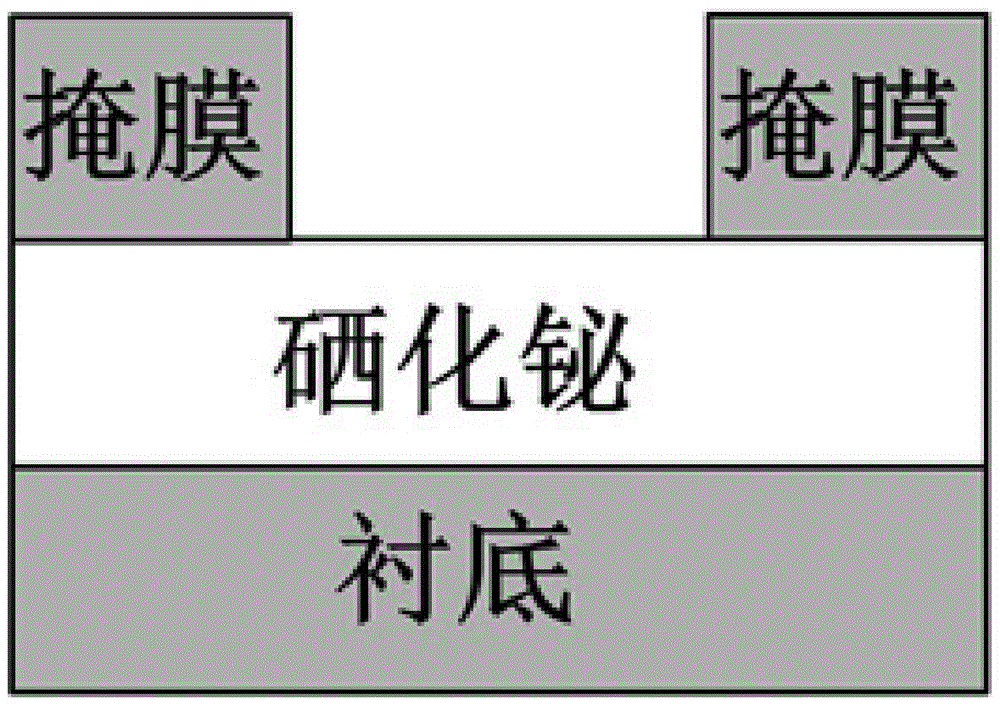

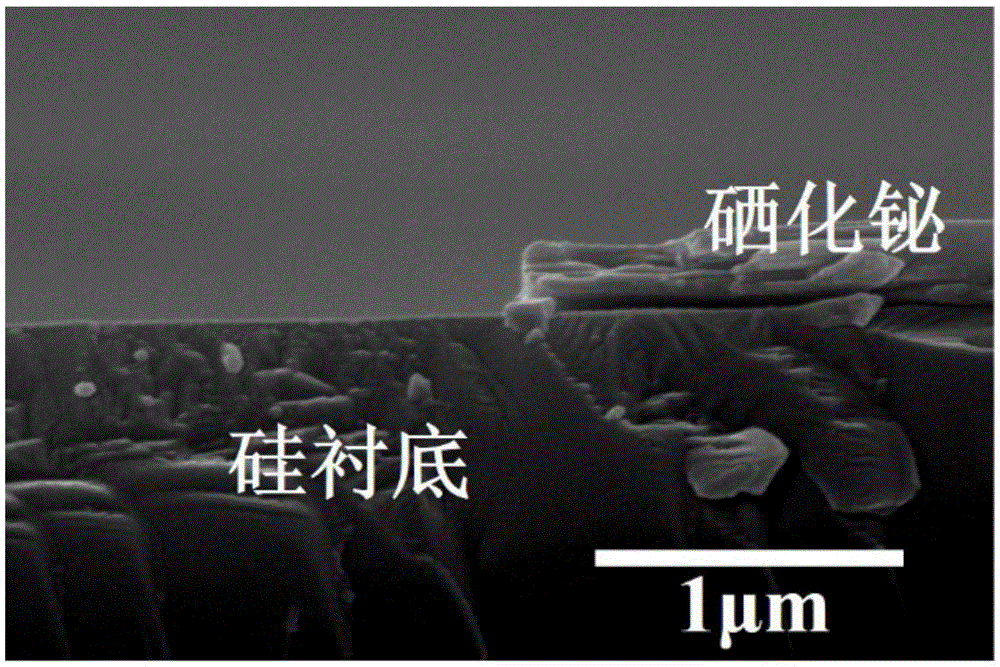

[0018] Embodiment 1: a kind of method that the epitaxial bismuth selenide single crystal thin film on the silicon substrate is etched, at first use standard photolithography technique to make on the bismuth selenide single crystal thin film epitaxial on the silicon substrate figure 2 The mask is shown, and the thickness h' of the mask is measured by a step meter; then potassium dichromate with a molar concentration of 0.02mol / L and a solution of concentrated sulfuric acid and concentrated hydrochloric acid with a volume ratio of 1.5:1 are used to prepare Potassium dichromate complex acid solution; use potassium dichromate complex acid solution to etch for 25 seconds, and measure the thickness h of the mask after etching with a step meter. Experiments have proved that the potassium dichromate compound acid solution has no corrosive effect on the mask, so h-h' is the thickness of etching. The etching was carried out stably at a speed of 150 nm / min, and finally a flat surface wa...

Embodiment 2

[0019] Embodiment 2: A kind of method is carried out etching bismuth selenide single crystal flake after cleavage, at first use standard photolithography technique to make on the bismuth selenide single crystal flake after cleaving figure 2 Shown mask, then with the potassium dichromate that molar concentration is 0.03mol / L, the concentrated sulfuric acid and the concentrated hydrochloric acid solution that volume ratio is 1.5:1, make potassium dichromate compound acid solution; Use dichromate The potassium compound acid solution was etched for 30 seconds, and the etching thickness was measured to be 120nm by using a step meter, and the etching rate was obtained to be 60nm / min, and finally a flat surface was obtained on the surface of the bismuth selenide single crystal.

Embodiment 3

[0020] Embodiment 3: a kind of method that the bismuth selenide single crystal thin film epitaxial on silicon substrate (film thickness 300nm) is etched, at first use standard photolithography technique on the bismuth selenide single crystal thin film epitaxial on silicon substrate made as figure 2 Shown mask, then with the potassium dichromate that molar concentration is 0.012mol / L, the concentrated sulfuric acid and the concentrated hydrochloric acid solution that volume ratio is 1.5:1, make potassium dichromate compound acid solution; Use dichromate After the potassium compound acid solution was etched for 20 seconds, the etching thickness was measured to be 150 nm, and the etching rate was obtained to be 450 nm / min. A flat surface was obtained on the surface of the bismuth selenide single crystal, and the surface did not deviate from the stoichiometric ratio as measured by EDS.

[0021] The above method for etching intrinsic bismuth selenide material is also applicable to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com