Method for detecting caprolactam in chinlon textile

A caprolactam and detection method technology, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of impurities and matrix spectral interference, low response and sensitivity, and poor detector targeting, so as to eliminate matrix and impurities. Accurate and precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

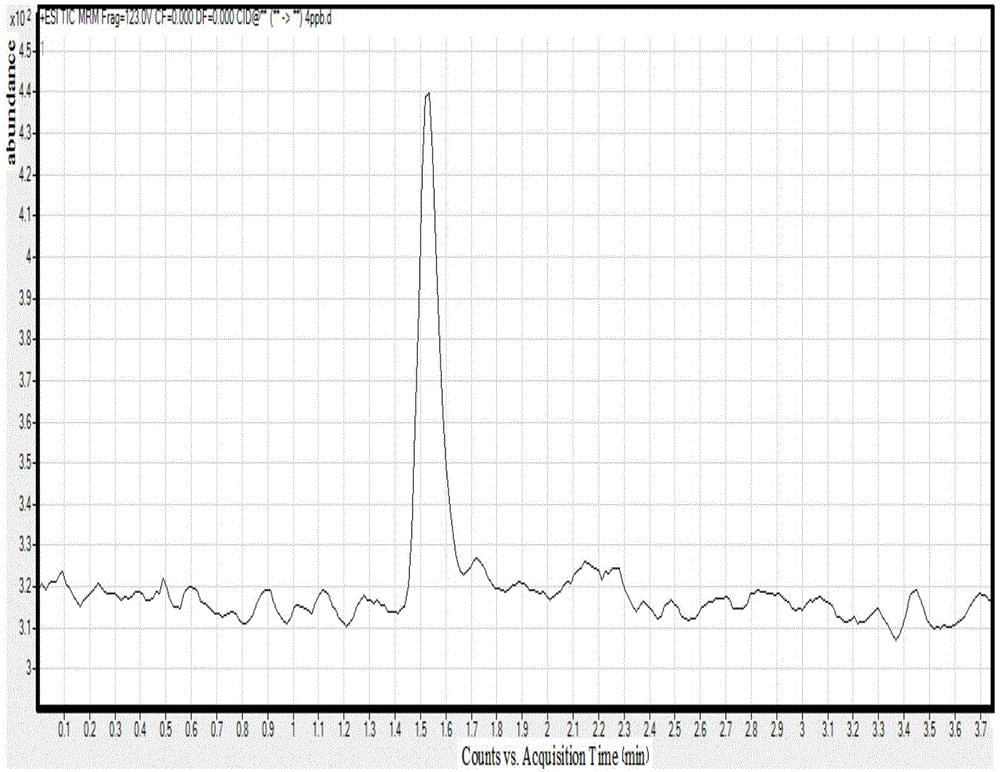

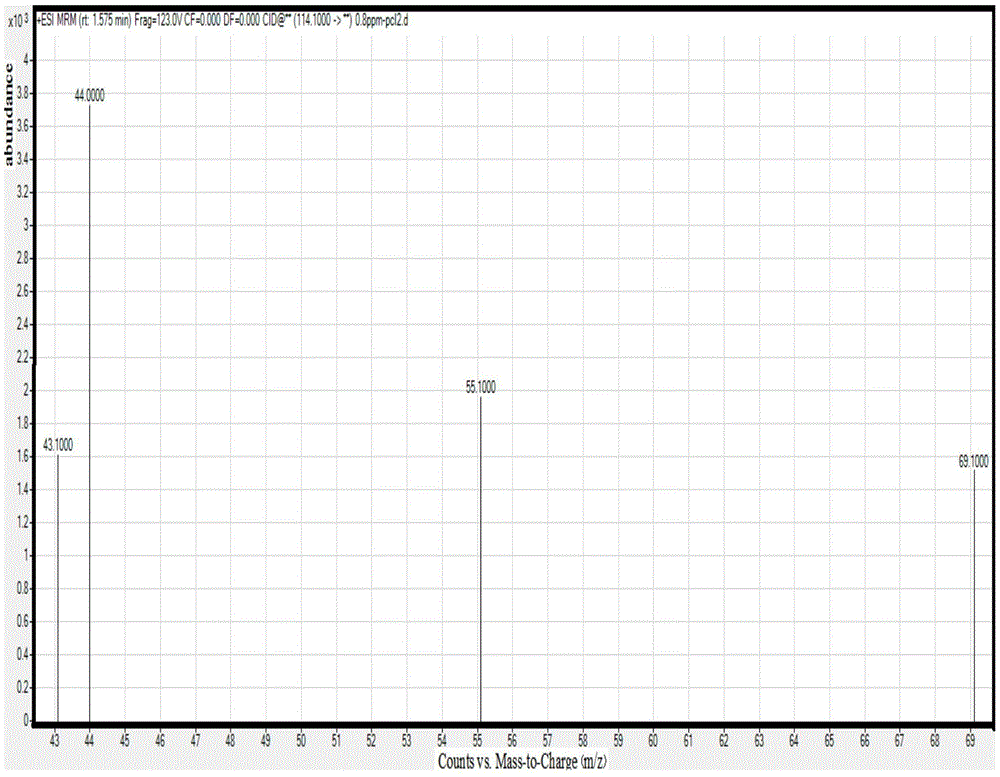

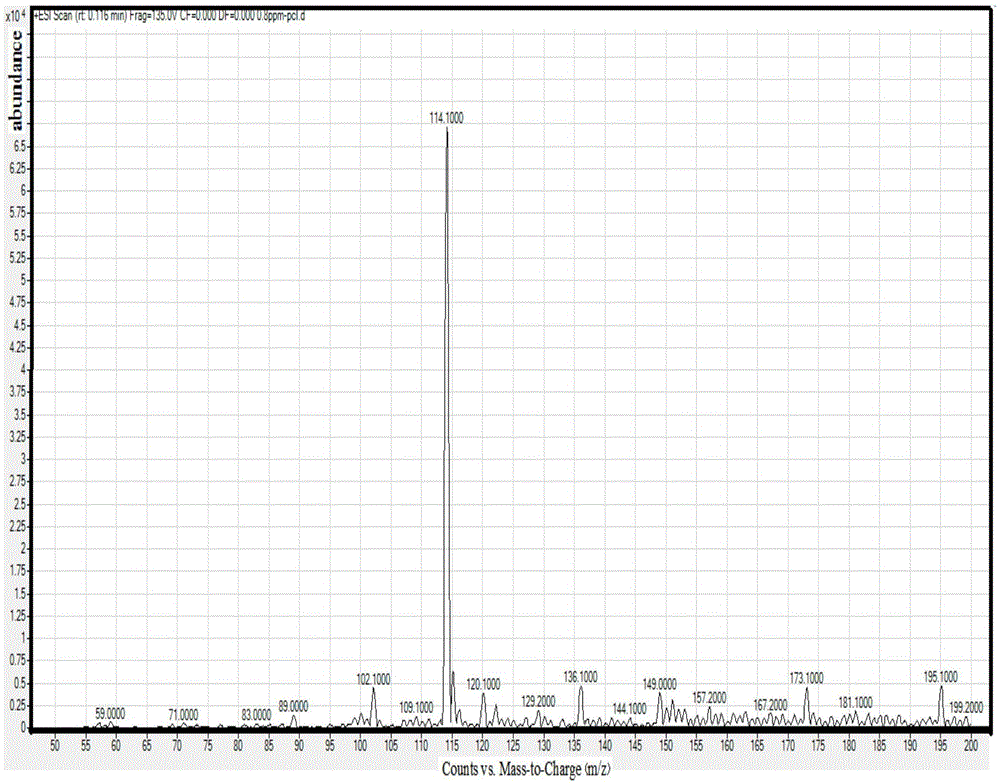

[0070] see Figure 1-4 . The invention discloses the drawing of the standard working curve of caprolactam, using an electronic balance of 1 / 10,000 to weigh 0.0817g caprolactam standard product (purity is 98%), put it in a 100mL volumetric flask, dissolve it with methanol and set the volume to the scale line, Shake well to prepare a caprolactam stock solution with a concentration of 800mg / L; then pipette 1000uL of the caprolactam stock solution into a 100mL volumetric flask, dilute to the mark with methanol, and shake well to obtain a caprolactam intermediate solution with a concentration of 8mg / L; Pipette 50uL, 100uL, 200uL, 500uL, and 1000uL caprolactam intermediate solutions into five 100mL volumetric flasks, dilute to the mark with methanol, shake well, and obtain concentrations of 4ug / L, 8ug / L, 16ug / L, 40ug / L, 80ug / L caprolactam standard solution.

[0071] The above-mentioned standard solution was detected with an ultra-high performance liquid chromatography triple quadr...

Embodiment 2

[0075] see Figure 5 . The invention discloses a detection method for caprolactam in women's sweaters (acrylic 72.7%, nylon 27.3%). The nylon textiles are selected, shredded manually, and mixed uniformly. Select a sample with a size of 2mm*2mm, accurately weigh 1.0g of the shredded sample, accurate to 0.0001g, put it in a 40ml reaction tube, add 20.0ml of double distilled water, keep the temperature in an oven at 100°C for 1 hour, and then adjust the temperature at a frequency of Ultrasonic treatment in a 40kHz ultrasonic cleaner for 30min, take it out and cool to room temperature, shake up and down, filter into a clean extraction tube, use a needle syringe to pass the supernatant through a 0.23um water filter membrane to obtain the test solution.

[0076] Repeat the above preparation process of the test solution 3 times to obtain 3 parallel samples A, B and C of the test solution.

[0077] The above three parallel samples were detected with an ultra-high performance liquid ...

Embodiment 3

[0085] see Figure 6 . The invention discloses a method for detecting caprolactam content in supersoft nylon one-piece trousers (56.1% polyester fiber, 31% nylon, and 12.9% spandex). The above-mentioned nylon textiles are selected, shredded manually, and mixed uniformly. Select a sample with a size of 2mm*2mm, accurately weigh 1.0g of the shredded sample, accurate to 0.0001g, put it in a 40ml reaction tube, add 18.0ml of double distilled water, keep the temperature in an oven at 80°C for 90min, and then at a frequency of 40kHz Ultrasonic treatment in an ultrasonic cleaner for 20 minutes, take it out and let it cool to room temperature, shake it up and down, filter it into a clean extraction tube, use a needle syringe to pass the supernatant liquid through a 0.22um water filter membrane, and obtain the test solution.

[0086] Repeat the above preparation process of the test solution 3 times to obtain 3 parallel samples A, B and C of the test solution.

[0087] The above three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com