Biofuel cell anode of enzymatic glycerin and preparation method and application of biofuel cell anode

A technology of biofuel cell and glycerin, which is applied in the field of electrochemical enzyme biofuel cell, can solve the problems of short battery life and achieve the effect of increasing load capacity, good catalytic performance and increasing load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

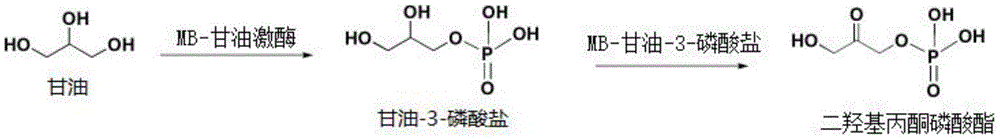

Method used

Image

Examples

Embodiment 1

[0032] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, and then the glassy carbon electrode is placed in 0.5mol / L H 2 SO 4 The electrode is activated in the solution, taken out, rinsed with distilled water, and dried to obtain a pretreated glassy carbon electrode;

[0033] (2) Take 6 μL of Nafion methanol solution with a mass fraction of 0.5% and drop it on the surface of the pretreated glassy carbon electrode, and place it at room temperature for about 1.5h. After the solvent on the electrode surface evaporates, a layer of Nafion film is formed; then insert the electrode Soak in an aqueous solution containing 0.1mmol / L Meldola blue (prepared by adding 3.8mg Meldola blue to 100mL distilled water), so that Meldola blue can be fixed on the Na...

Embodiment 2

[0039] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, and then the glassy carbon electrode is placed in 0.5mol / L H 2 SO 4 The electrode is activated in the solution, taken out, rinsed with distilled water, and dried to obtain a pretreated glassy carbon electrode;

[0040] (2) Take 6 μL of Nafion methanol solution with a mass fraction of 0.5% and drop it on the surface of the pretreated glassy carbon electrode, and place it at room temperature for about 1.5h. After the solvent on the electrode surface evaporates, a layer of Nafion film is formed; then insert the electrode Soak in an aqueous solution containing 0.1mmol / L Meldola blue (prepared by adding 3.8mg Meldola blue to 100mL distilled water), so that Meldola blue can be fixed on the Na...

Embodiment 3

[0045] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, and then the glassy carbon electrode is placed in 0.5mol / L H 2 SO 4 The electrode is activated in the solution, taken out, rinsed with distilled water, and dried to obtain a pretreated glassy carbon electrode;

[0046] (2) Take 6 μL of Nafion methanol solution with a mass fraction of 0.5% and drop it on the surface of the pretreated glassy carbon electrode, and place it at room temperature for about 1.5h. After the solvent on the electrode surface evaporates, a layer of Nafion film is formed; then insert the electrode Soak in an aqueous solution containing 0.1mmol / L Meldola blue (prepared by adding 3.8mg Meldola blue to 100mL distilled water), so that Meldola blue can be fixed on the Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com