Preparation method of high-concentration natural apple essence

An apple essence and high-concentration technology, which is applied in food science and other fields, can solve the problems of wasting resources, low concentration multiples, and loss of business opportunities, and achieve the effects of high production efficiency, increased specific surface area, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

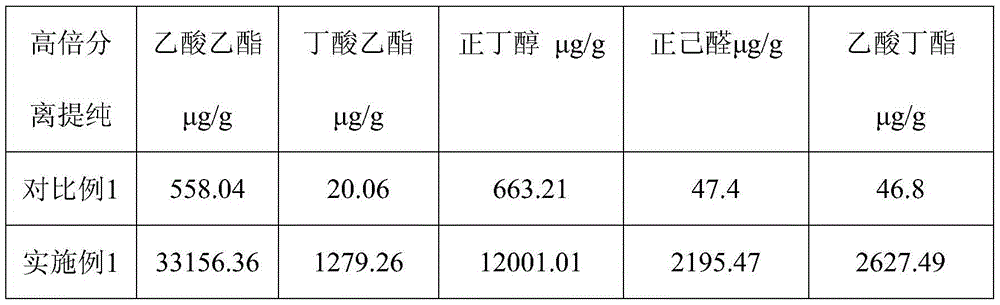

Examples

Embodiment 1

[0042] 1) Preparation of raw materials: Red Fuji apples are used as raw materials, including receiving, sorting and cleaning of raw materials.

[0043] 2) Crushing: Use a spiral rotary disc crusher to break the raw materials into 0.3-0.6cm blocks.

[0044] 3) Enzymolysis: Put the crushed raw materials into a buffer tank, add compound biological enzymes, and carry out enzymolysis. Wherein, the addition amount of the compound biological enzyme is 70 parts per million of the mass of the broken apple; the enzyme activity of the compound biological enzyme is 5 EPU / mL; and the compound biological enzyme consists of xylanase, β-glucose, polysaccharide Consists of galacturonase, protease, amylase, cellulase, and hemicellulase; the enzymatic hydrolysis time is 50 minutes.

[0045] 4) Squeeze: Squeeze out the juice from the crushed fruit pulp, and collect the juice in a buffer tank.

[0046] 5) Fragrance enhancement: After the juice is heated to 100°C, it enters the aroma enhancement ...

Embodiment 2

[0056] 1) Preparation of raw materials: Red Fuji apples are used as raw materials, including receiving, sorting and cleaning of raw materials.

[0057] 2) Crushing: Use a spiral rotary disc crusher to break the raw materials into 0.3-0.6cm blocks.

[0058] 3) Enzymolysis: Put the crushed raw materials into a buffer tank, add compound biological enzymes, and carry out enzymolysis. Among them, the addition amount of the compound biological enzyme is 70 parts per million of the mass of the broken apple; the enzyme activity of the compound biological enzyme is 5 EPU / mL; and the compound biological enzyme is composed of xylanase, β-glucose, polysaccharide Consists of galacturonase, protease, amylase, cellulase, and hemicellulase; the enzymatic hydrolysis time is 30 minutes.

[0059] 4) Squeeze: Squeeze out the juice from the crushed fruit pulp, and collect the juice in a buffer tank.

[0060] 5) Fragrance enhancement: After the juice is heated to 105°C, it enters the aroma enhanc...

Embodiment 3

[0067] 1) Preparation of raw materials: Red Fuji apples are used as raw materials, including receiving, sorting and cleaning of raw materials.

[0068] 2) Crushing: Use a spiral rotary disc crusher to break the raw materials into 0.3-0.6cm blocks.

[0069] 3) Enzymolysis: Put the crushed raw materials into a buffer tank, add compound biological enzymes, and carry out enzymolysis. Among them, the addition amount of the compound biological enzyme is 70 parts per million of the mass of the broken apple; the enzyme activity of the compound biological enzyme is 5 EPU / mL; and the compound biological enzyme is composed of xylanase, β-glucose, polysaccharide Consists of galacturonase, protease, amylase, cellulase, and hemicellulase; the enzymatic hydrolysis time is 60 minutes.

[0070] 4) Squeeze: Squeeze out the juice from the crushed fruit pulp, and collect the juice in a buffer tank.

[0071] 5) Fragrance enhancement: After the juice is heated to 102°C, it enters the aroma enhanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com