Low-protein starch paste easy in brewing and preparation method thereof

A low-protein, starch paste technology, applied in the field of food processing, can solve the problems that patients cannot eat for a long time, has not yet been discovered, and has poor taste after processing, and achieves the effects of being conducive to digestion, absorption and utilization, good physiological function, and good flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

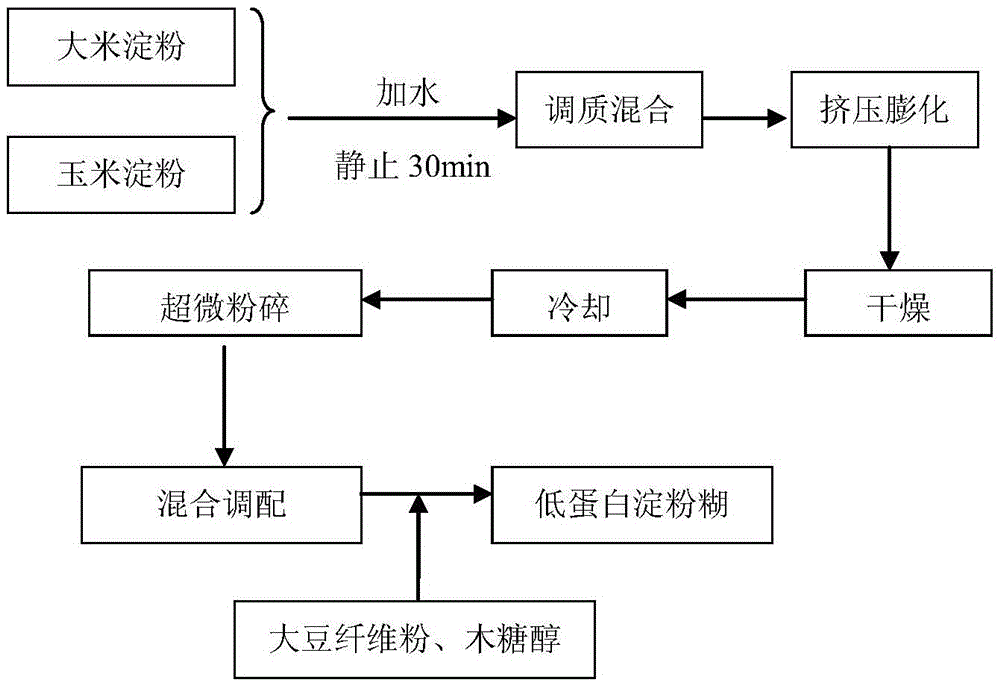

[0023] Weigh 45% of rice starch and 40% of corn starch that have passed through a 100-mesh sieve, and pour them into the solid feeder. While feeding, slowly add water from the water inlet to make the moisture content of the material 30%. Add the material to the multi-gradient physical In the extrusion and expansion generator in the field generator, the conditions are set as the extrusion temperature: the temperature of the first sleeve is 50°C, the temperature of the second sleeve is 100°C, and the temperature of the third sleeve is 180°C. The screw speed is 180r / min, the moisture content is 30%, and the feeding speed is 18kg / h. The extruded material is placed in a dryer and dried at 80°C until the moisture content reaches below 8%. Cool the dried sample , and then use a superfine pulverizer to pulverize for 30 minutes, pulverize until more than 95% of the samples can pass through a 200-300 mesh sieve, and the pulverized particle size is 18 microns. The superfine pulverized mat...

Embodiment 2

[0025] Weigh 50% of rice starch and 35% of corn starch that have passed through a 100-mesh sieve, and pour them into the solid feeder. While feeding, slowly add water from the water inlet to make the moisture content of the material 20%. Add the material to the multi-gradient physical In the extrusion and expansion generator in the field generator, the conditions are set as the extrusion temperature: the temperature of the first sleeve is 50°C, the temperature of the second sleeve is 110°C, and the temperature of the third sleeve is 190°C. The screw speed is 200r / min, the moisture content is 20%, and the feeding speed is 20kg / h. The extruded material is placed in a dryer and dried at 70°C until the moisture content is below 8%. Cool the dried sample , and then use a superfine pulverizer to pulverize for 30 minutes, pulverize until more than 95% of the samples can pass through a 200-300 mesh sieve, and the pulverized particle size is 18 microns. The superfine pulverized material...

Embodiment 3

[0027] Weigh 48% of rice starch and 37% of corn starch that have passed through a 100 mesh sieve, and pour them into the solid feeder. While feeding, slowly add water from the water inlet to make the moisture content of the material 25%. Add the material to the multi-gradient physical In the extrusion and expansion generator in the field generator, the conditions are set as the extrusion temperature: the temperature of the first sleeve is 50°C, the temperature of the second sleeve is 100°C, and the temperature of the third sleeve is 200°C. The screw speed is 220r / min, the moisture content is 25%, and the feeding speed is 24kg / h. The extruded material is placed in a dryer and dried at 70°C until the moisture content reaches below 8%. Cool the dried sample , and then use a superfine pulverizer to pulverize for 30 minutes until more than 95% of the samples can pass through a 200-300 mesh sieve, and the pulverized particle size is 18 microns. The superfine pulverized material is mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com