Activated sludge treatment method and system for wastewater

A technology of activated sludge and treatment method, which is applied in the field of activated sludge treatment system for wastewater treatment, and can solve the problems of waste of air aeration energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

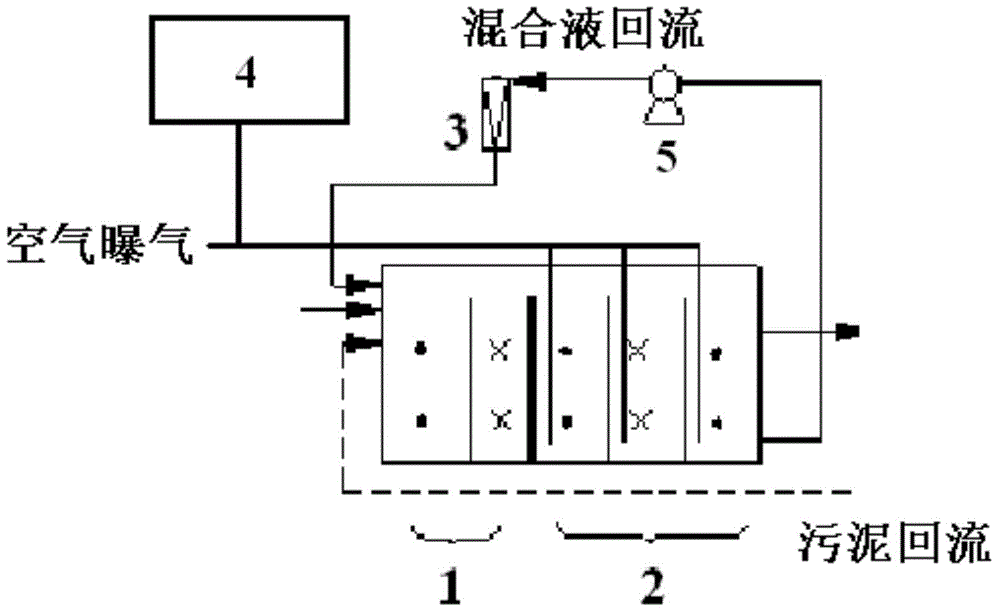

[0060] like figure 2As shown, according to another preferred embodiment of the present invention, the system further includes a carbon dioxide supply unit 4 communicated with the aerobic unit.

[0061] According to the present invention, the carbon dioxide supply unit is preferably a hydrogen production device. By connecting with the hydrogen production device, the gas discharged from the hydrogen production device can be supplied to the aerobic unit 2 through the carbon dioxide vent pipe. Thereby, the gas exhausted from hydrogen production is recovered and utilized, which is beneficial to the protection of the atmospheric environment.

[0062] According to the present invention, the system can also include a homogeneous unit and an air flotation separation unit arranged in sequence to realize the homogeneity and air flotation separation of wastewater. Aerobic unit 2 upstream.

[0063] According to a particularly preferred embodiment of the present invention, in actual use...

Embodiment 1-4

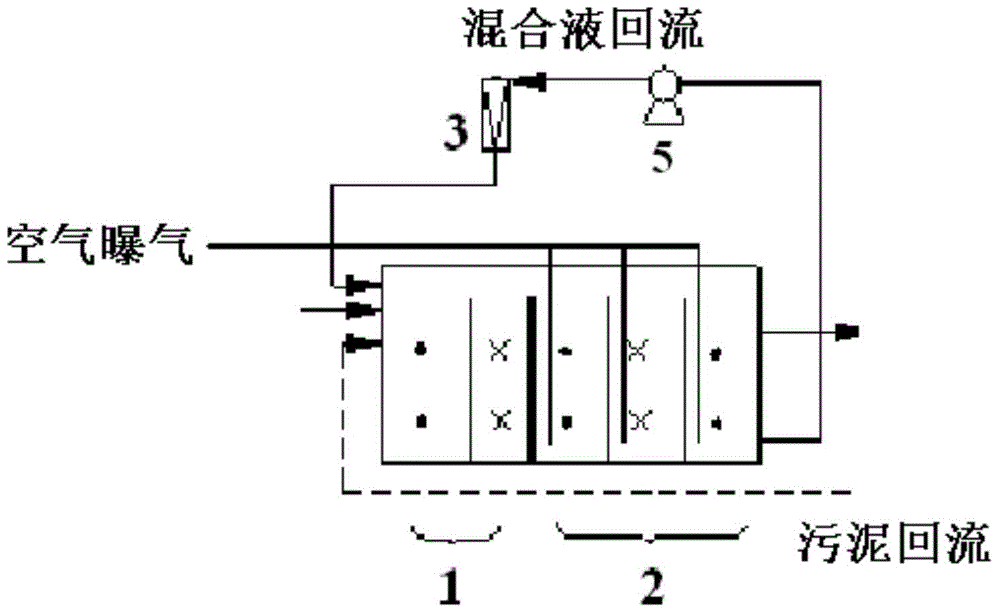

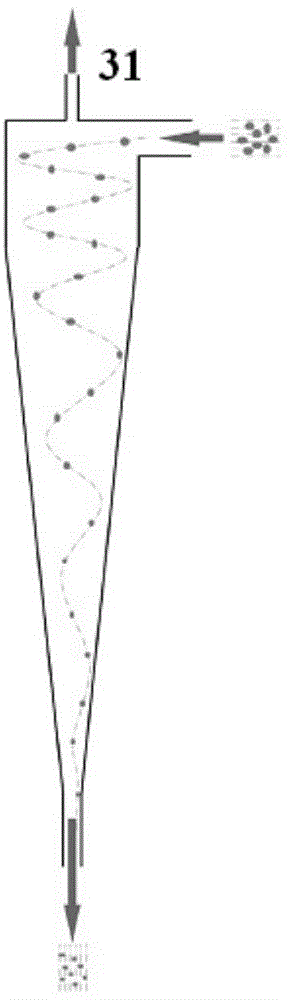

[0078] use figure 1 The shown device respectively carries out activated sludge treatment (including anoxic treatment and aerobic treatment) to electric desalination wastewater 1, saline wastewater 1, oily wastewater 1 and stripping wastewater 1. Pollution Control Engineering, Pages 342-344: Water Pollution Control Engineering, edited by Wang Yu, deputy editor by Lin Fengkai, Chemical Industry Press, 2008". The difference is that a cyclone is set on the return line from aerobic to anaerobic, the flow rate of the cyclone inlet is 4-6m / s, the feed pressure is 0.10-0.15MPa, the inlet and outlet The pressure difference of the cyclone is 0.10-0.15MPa, the flow rate of the overflow port of the cyclone is 3.5 volume% of the inlet flow rate, and the velocity gradient of the mixed material (reflux liquid) from the aerobic treatment in the cyclone is 4000S -1 . The particle size of 80% by weight of activated sludge flocs after cyclone is 0.5-1mm, and the particle diameter of all activa...

Embodiment 5-8

[0080] use figure 1 The shown device performs activated sludge treatment (including anoxic treatment and aerobic treatment) on electric desalination wastewater 2 , saline wastewater 2 , oily wastewater 2 and stripping wastewater 2 respectively. The treatment method is carried out according to ""Water Pollution Control Engineering" pages 342-344: Water Pollution Control Engineering, editor-in-chief Wang Yu, deputy editor-in-chief Lin Fengkai, Chemical Industry Press, 2008". The difference is that a cyclone is set on the return line from aerobic to anaerobic, the flow rate of the cyclone inlet is 1-4m / s, the feed pressure is 0.03-0.06MPa, the inlet and outlet The pressure difference of the cyclone is 0.06MPa, the flow rate of the overflow port of the cyclone is 2% by volume of the inlet flow rate, and the velocity gradient of the mixed material (reflux liquid) from the aerobic treatment in the cyclone is 2800S -1 . The particle size of 60% by weight of activated sludge flocs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com