Hydrolysis resistant aluminum nitride powder, and preparation method and application thereof

An aluminum nitride and hydrolysis-resistant technology, applied in the field of colloid chemistry, can solve the problems of increasing oxygen content and affecting the fluidity of water-based aluminum nitride slurry, and achieves no reduction in thermal conductivity, significant industrial application value, and scope of application. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 150g of aluminum nitride powder and 100mL of ethanol into a ball mill jar, and mill for 10 minutes to obtain aluminum nitride slurry; take 1.5g of single-component polyurethane (water-based polyurethane grouting solution, purchased from Shanghai Jiankuo Industrial Co., Ltd.) Add it to the aluminum nitride slurry and continue ball milling for 1 hour to obtain a mixed slurry; pour the mixed slurry into a tray and dry it directly at 70°C for at least 12 hours to obtain a hydrolysis-resistant aluminum nitride powder.

Embodiment 2

[0029] Add 150g of aluminum nitride powder and 100mL of ethanol into the ball milling tank, and mill for 10 minutes to obtain aluminum nitride slurry; take 1g of two-component polyurethane isocyanate component (MDI) and add it to the aluminum nitride slurry, continue Ball mill for 1 hour, then pour the aluminum nitride slurry into a beaker, add 0.5 g of a two-component polyurethane curing agent component (polyether 204, hydroxyl value 265-300 mgKOH / g) while stirring, and continue stirring for 1 hour. hours to obtain a mixed slurry; pour the mixed slurry into a tray and directly dry at 70°C for at least 12 hours to obtain a hydrolysis-resistant aluminum nitride powder.

Embodiment 3

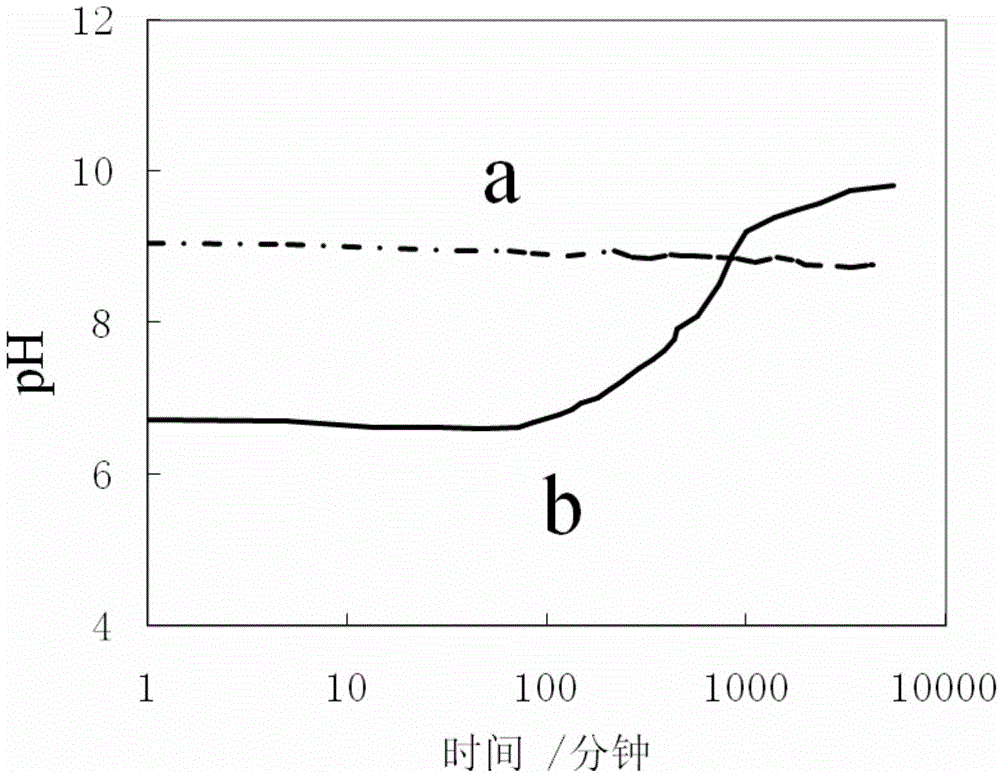

[0031] Add 150 g of aluminum nitride powder and 100 mL of ethanol into a ball milling tank, and mill for 10 minutes to obtain aluminum nitride slurry; take polyol-modified single-component polyurethane (purchased from Shanghai Crane City Polymer Technology Co., Ltd.) 1.5 g was added to the aluminum nitride slurry, and ball milling was continued for 1 hour to obtain a mixed slurry; the mixed slurry was poured into a tray and dried directly at 70°C to obtain a hydrolysis-resistant aluminum nitride powder. Disperse the aluminum nitride powder obtained in this example in water at a mass fraction of 10%, test and record the pH value of the suspension every 20 minutes, stir continuously during the test, and at the same time use the Ordinary aluminum nitride powder is used as a comparative test, and the pH value and time are plotted to obtain figure 1 The aluminum nitride hydrolysis process curve shown by figure 1 It can be seen that the aluminum nitride powder without polyurethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com