Method for catalytic reduction of m-nitroacetophenone for preparation of m-aminoacetophenone

A technology for nitroacetophenone and aminoacetophenone, which is applied in the field of catalytic synthesis of fine chemicals, can solve the problems of increased cost and high difficulty in product selectivity control, and achieves high application times, low equipment requirements, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

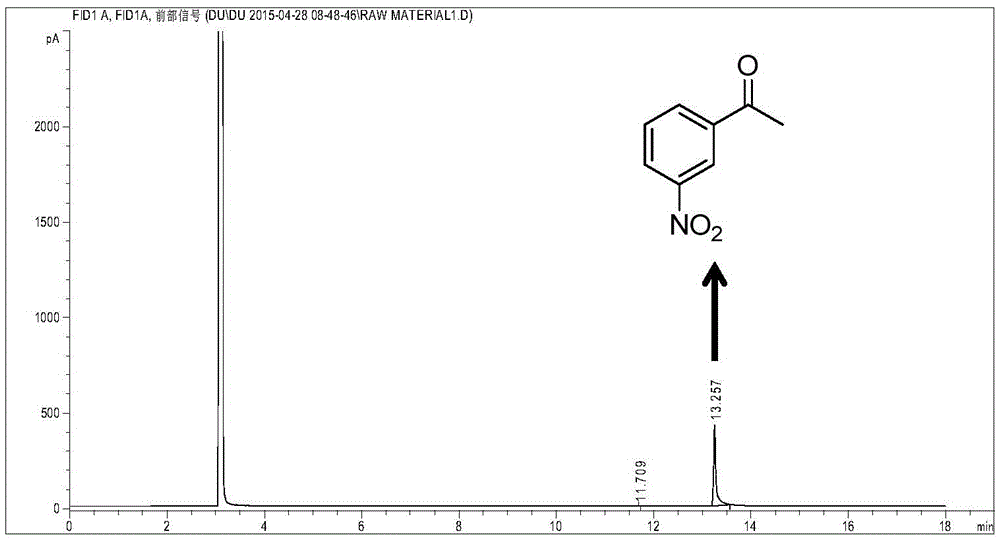

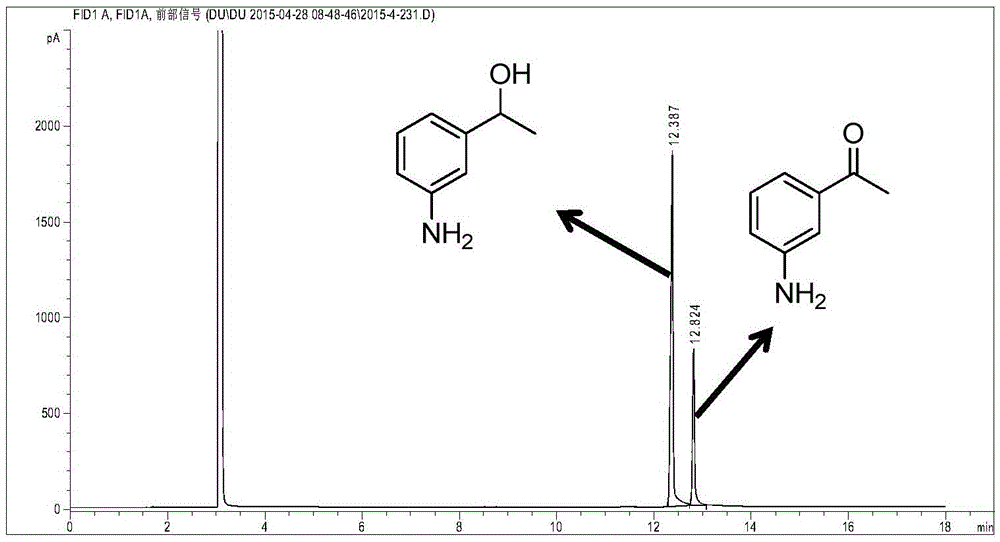

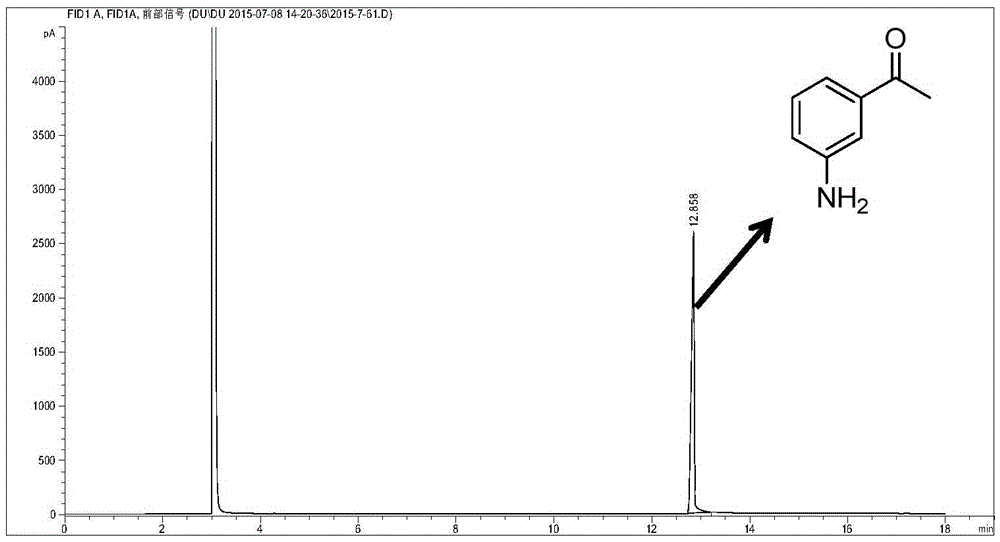

Embodiment 1

[0016] 2.0g m-nitroacetophenone, 0.2gPt / Bi 2 o 3 (Pt content is 0.2wt%), add 10mL of anhydrous methanol into a 50mL batch reactor, replace the gas in the reactor with nitrogen and hydrogen successively for 3-5 times, fill in hydrogen to a pressure of 1.0MPa, and heat up to 70 °C, the stirring speed is 600-800 rpm. If the total pressure drops below 0.5MPa, add hydrogen to the initial pressure. After 4h, the total pressure did not change any more, the stirring was stopped, and it was cooled to room temperature. Centrifuge the reaction mixture, the bottom is a yellow catalyst, and the supernatant is green (if m-nitroacetophenone is not completely converted, the supernatant is yellow-green, and the by-products include nitroso compounds, which are partially hydrogenated products of nitro groups) . Get a small amount of supernatant and adopt gas chromatography analysis, m-nitroacetophenone conversion rate is greater than 99.9%, m-aminoacetophenone selectivity is greater than 99....

Embodiment 2

[0019] 2.0g m-nitroacetophenone, 0.2gPt / Bi 2 o 5 (Pt content is 0.2wt%), add 10mL of absolute ethanol into a 50mL batch reactor, replace the gas in the reactor with nitrogen and hydrogen successively for 3-5 times, fill in hydrogen to a pressure of 0.1MPa, and heat up to 40 °C, the stirring speed is 600-800 rpm. If the total pressure drops, hydrogen is added to the initial pressure. After 10 hours, the total pressure did not change any more, the stirring was stopped, and it was cooled to room temperature. A small amount of supernatant was taken and analyzed by gas chromatography, the conversion rate of m-nitroacetophenone was greater than 99.9%, and the selectivity of m-aminoacetophenone was greater than 99.9%. The product m-aminoacetophenone was obtained after the methanol in the filtrate was removed by rotary evaporation, and the separation yield was 98%.

Embodiment 3

[0021] Add the catalyst recovered in Example 1 and 10 mL of anhydrous methanol into a 50 mL batch reactor, add 2.0 g of m-nitroacetophenone, replace the gas in the reactor with nitrogen and hydrogen successively for 3-5 times, and fill with hydrogen To a pressure of 1.0 MPa, the temperature was raised to 70°C under constant stirring, and the stirring speed was 600-800 rpm. If the total pressure drops, hydrogen is added to the initial pressure. After a certain period of time (see Table 1), the total pressure does not change any more, stop stirring, and cool to room temperature. A small amount of supernatant was taken and analyzed by gas chromatography, the conversion rate of m-nitroacetophenone was greater than 99.9%, and the selectivity of m-aminoacetophenone was greater than 99.9%. According to the above method, the catalyzer is recycled, and the specific results are shown in the following table:

[0022]

[0023] It can be seen from the table that the catalyst still has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com