Method for comprehensively extracting tea essence, tea polysaccharides and tea polyphenol

A technology for comprehensive extraction and tea essence, which is applied in the field of comprehensive extraction of tea essence, tea polysaccharides and tea polyphenols, can solve the problems of poor softness, impure aroma, and high cost, and achieve simple process, good economic benefits, application prospects, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

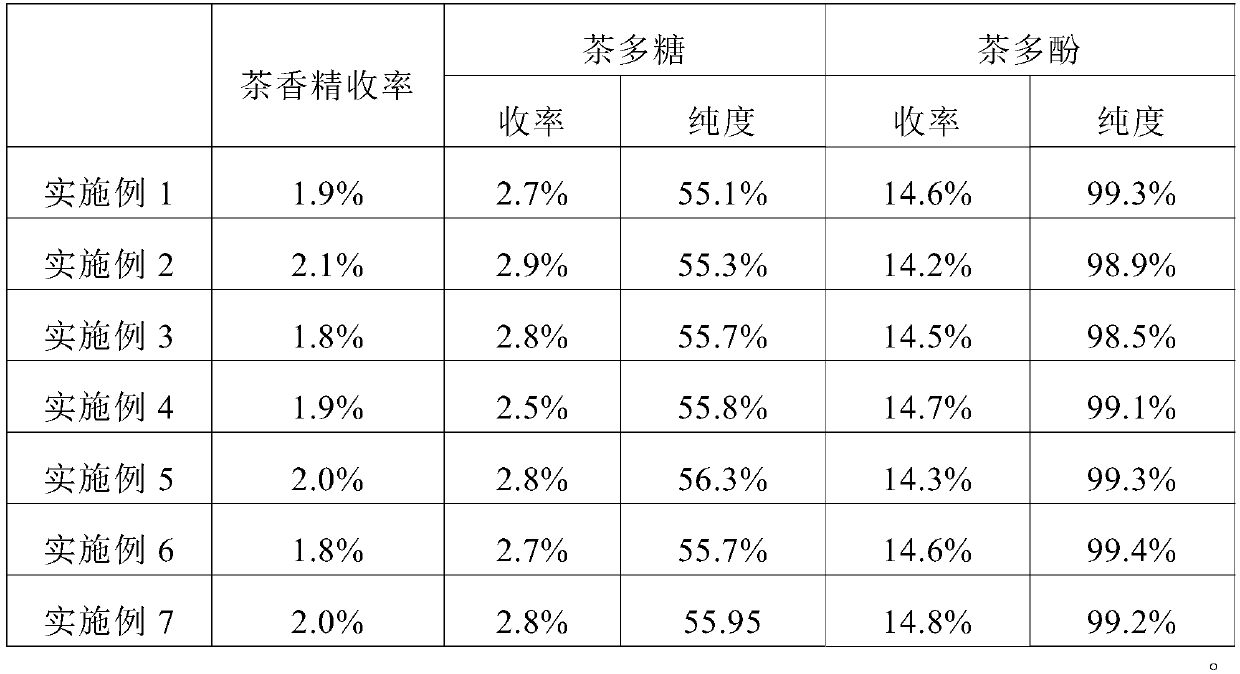

Embodiment 1

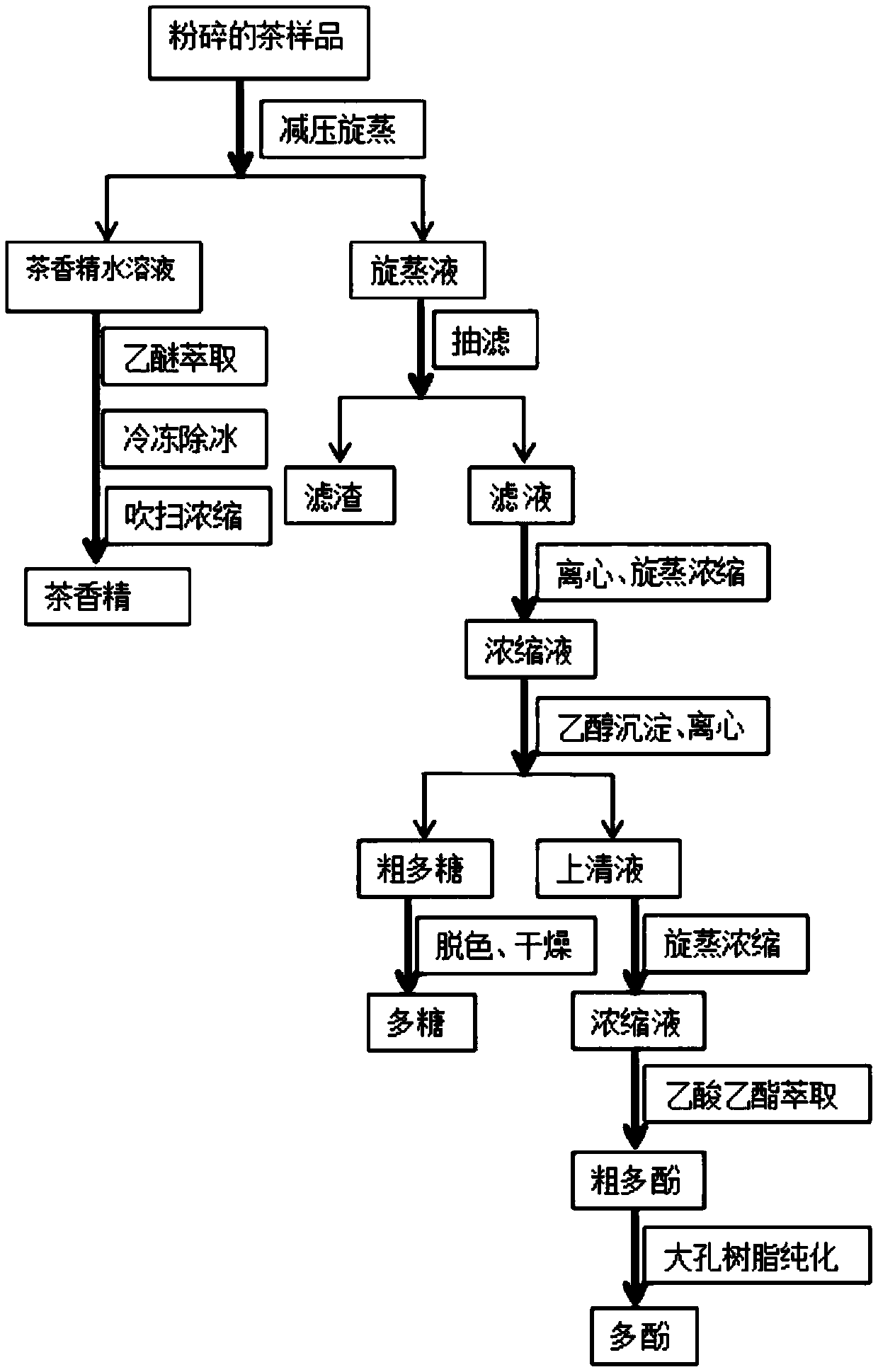

[0023] A comprehensive extraction method of tea essence, tea polysaccharides and tea polyphenols, the process route is as follows figure 1 As shown, the specific steps are as follows:

[0024] (1) After pulverizing the oolong tea, sieve it through an 80-mesh sieve.

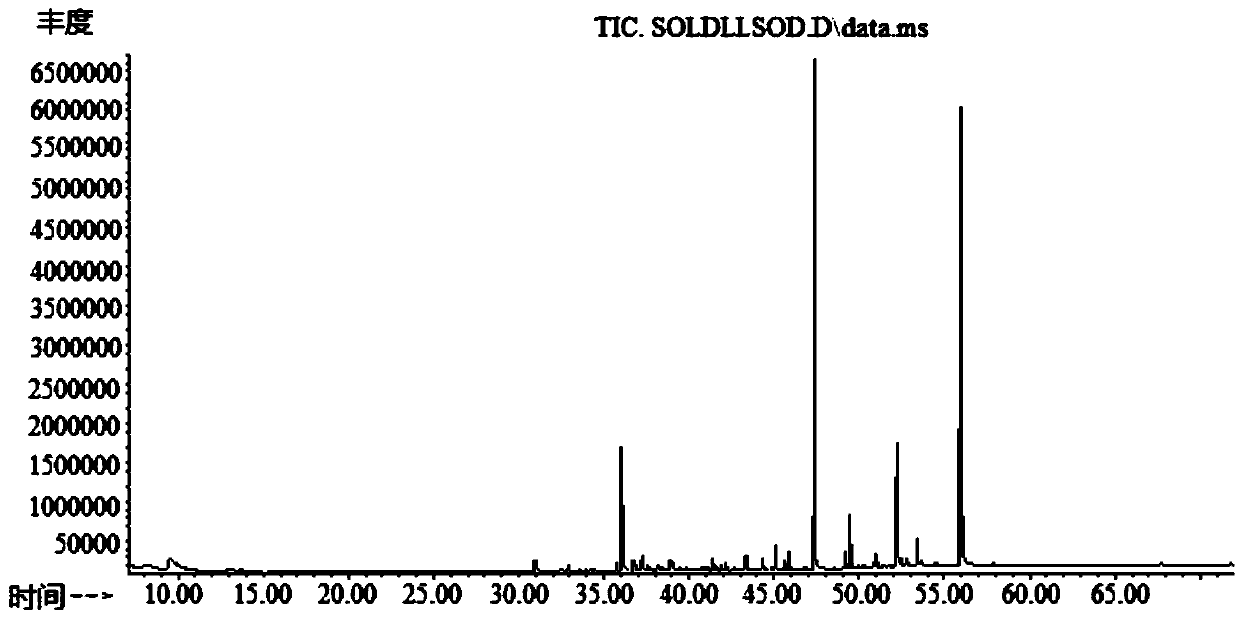

[0025] (2) Tea samples are rotary steamed under reduced pressure and extracted with ether: add 12 times the volume of boiling distilled water to Zhangping Shuixian Oolong tea powder, and extract the tea essence by rotary steaming under reduced pressure at 60°C and 0.08-0.10MPa vacuum for 40 minutes. Repeat the extraction twice according to the above method, combine the distillate, and then extract the distillate twice with 1 / 40 volume of double-distilled ether. The ether extract is frozen and deiced below zero degrees Celsius to remove water, and then slowly purged with nitrogen to concentrate Ether extract to obtain high-quality and high-concentration tea essence. The total ion chromatogram of tea essence is as...

Embodiment 2

[0029] A comprehensive extraction method for tea essence, tea polysaccharides and tea polyphenols, using the following steps:

[0030] (1) After the tea tree flower is pulverized, sieve through an 80-mesh sieve.

[0031] (2) Tea samples are rotary steamed under reduced pressure and extracted with ether: Add 15 times the volume of boiling distilled water to the camellia japonica powder, and extract the tea essence by rotary steaming under reduced pressure at 50°C and 0.10 MPa vacuum for 60 minutes. Repeat the extraction twice according to the above method, combine the distillate, and then extract the distillate twice with 1 / 20 volume of ether. The ether extract is frozen and deiced below zero degrees Celsius to separate the water, and then slowly purged with nitrogen to concentrate the ether extract. , to obtain high-quality and high-concentration tea essence. The rotary distilled liquid was suction-filtered with a single layer of nylon gauze, and the filter residue was sonica...

Embodiment 3

[0035] A comprehensive extraction method for tea essence, tea polysaccharides and tea polyphenols, using the following steps:

[0036] (1) After the green tea is crushed, it is sieved through an 80-mesh sieve.

[0037] (2) Tea samples are rotary steamed under reduced pressure and extracted with ether: add 10 times the volume of boiling distilled water to the green tea powder, and extract the tea essence by rotary steaming under reduced pressure at 60°C and 0.10 MPa vacuum for 45 minutes. Repeat the extraction twice according to the above method, combine the distillate, and then extract the distillate twice with 1 / 20 volume of ether. The ether extract is frozen and deiced below zero degrees Celsius to separate the water, and then slowly purged with nitrogen to concentrate the ether extract. , to obtain high-quality and high-concentration tea essence. The rotary distilled liquid was suction-filtered with a single layer of nylon gauze, and the filter residue was sonicated with 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com