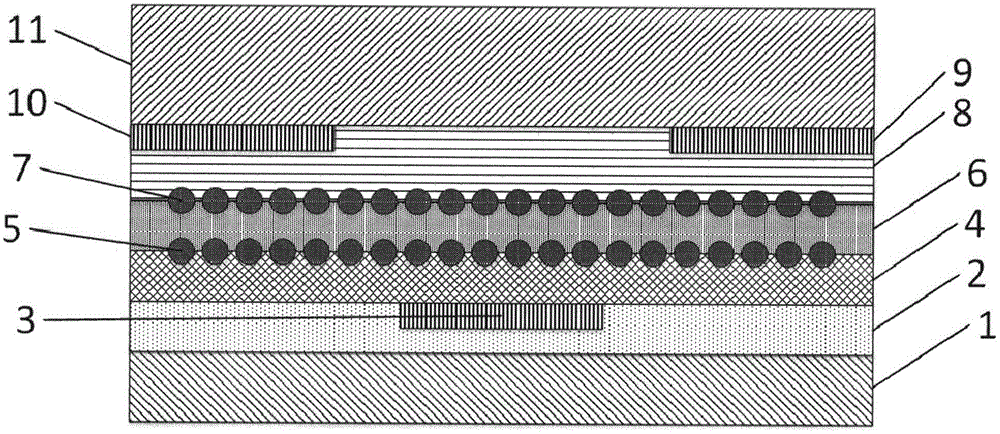

Dual-layer floating gate flexible organic memory device and preparation method therefor

A technology of organic storage devices and floating gates, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of device storage reliability decline, reduce leakage current, improve product yield, and excellent heat dissipation The effect of stability and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1.1 Cut the PET into a 2cm×2.5cm piece, then scrub it with detergent powder, and then use acetone, ethanol, and deionized water to ultrasonically clean it in an ultrasonic cleaner for 10 minutes;

[0027] 1.2 Blow dry 1 under nitrogen, then put it into a vacuum drying oven with a vacuum degree of 0.09Pa, and dry it for 2 hours.

Embodiment 2

[0029] 2.1 Weigh 15mg of purified graphene oxide powder with an electronic scale, weigh 1ml of absolute ethanol with a measuring cylinder, and mix them in a glass bottle;

[0030] 2.2 Seal the bottle and place it on a magnetic stirrer to stir for 1 hour to prepare a 15mg / ml solution;

Embodiment 3

[0032] 3.1 Put the sheet prepared in Example 1 on the suction head of the glue homogenizer, and drop the solution in Example 2 on 1 with a liquid dispenser;

[0033] 3.2 Set the homogenizer at low speed to 300 rpm for 3 seconds, high speed to 1000 rpm for 60 seconds, and start spin coating 2;

[0034] 3.3 After the spin coating is completed, put the sheet into a vacuum drying oven with a vacuum degree of 0.09Pa, a heating temperature of 80°C, and anneal for 2 hours. The thickness of 2 is 20nm after detection by a step meter;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com