Gas diffusion electrode and preparation and application thereof

A gas diffusion electrode and gas diffusion layer technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in ensuring uniformity, difficulty in large-scale preparation, and cumbersome post-processing, so as to improve dispersion effect and utilization rate , Improving the efficiency of electrochemical reaction and the effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The specific preparation process of the gas diffusion electrode includes:

[0037] (a) Preparation of gas diffusion layer

[0038] Mix VulcanXC-72 carbon powder with PTFE and prepare it on the surface of Toray-060 carbon paper by screen printing. The loading of VulcanXC-72 carbon powder is 0.5mg / cm 2 , PTFE loading is 40wt.%;

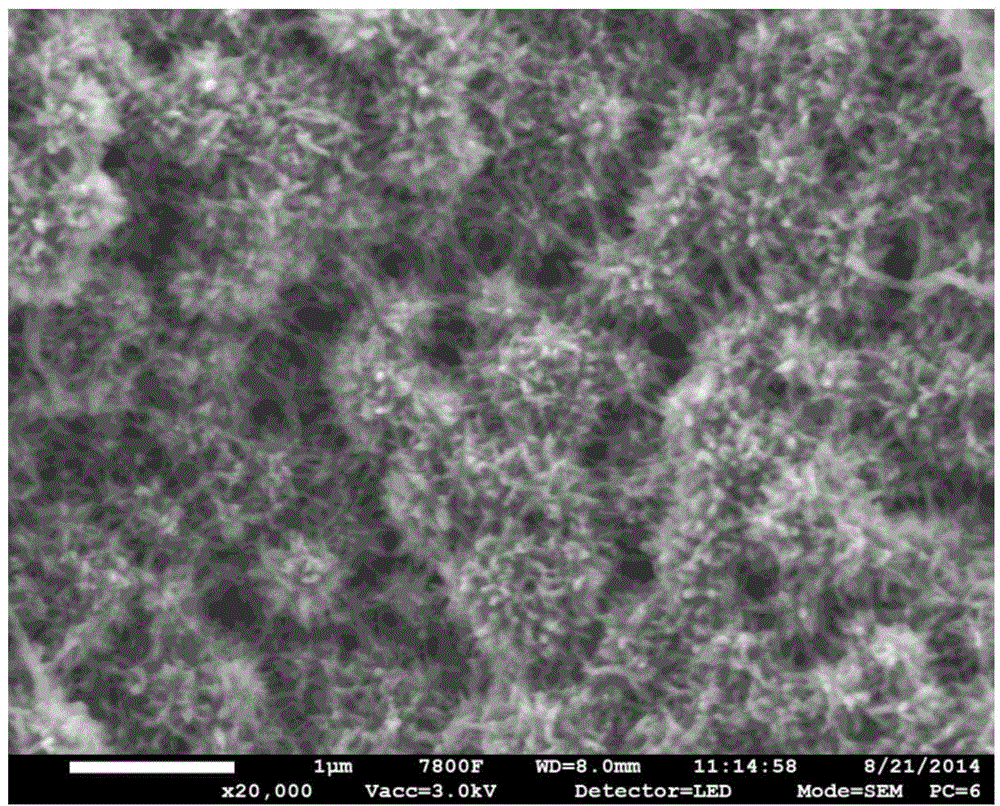

[0039] (b) Preparation of polyaniline nanorods

[0040] Add 0.183ml aniline (20mmol) in the 1mol / L perchloric acid aqueous solution of 100ml, record as solution A, then add 0.31g ammonium persulfate (13.6mmol) in another 100ml 1mol / L perchloric acid aqueous solution, record It is solution B, solutions A and B are mixed evenly at -5°C, then the concentration of aniline in the mixed solution is 10mmol / L, and the concentration of ammonium persulfate is 6.8mmol / L, and the gas diffusion layer is placed in the mixed solution, The microporous layer faces the solution, and the other side is sealed, and the surface of the microporous layer of the gas d...

Embodiment 2

[0045] The difference from Example 1 is that the polymerization reaction temperature is 0° C., and the aniline concentration is 5 mmol / L. All the other conditions are the same as in Example 1.

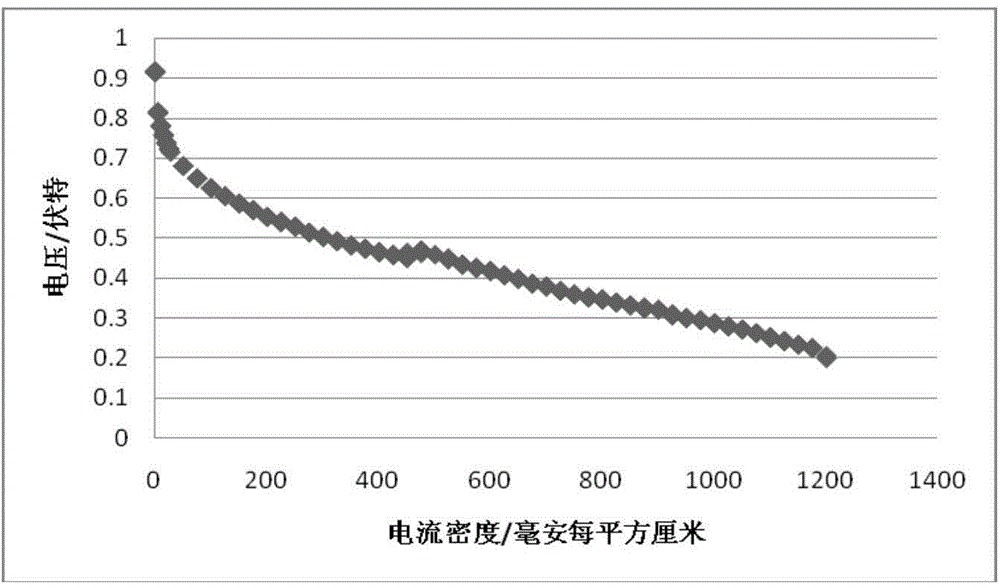

[0046] The IV curve of the single cell assembled with the gas diffusion electrode as the cathode is as follows: image 3 shown. The structure and composition of the single battery, and the discharge conditions of the single battery are as follows:

[0047] Single cell structure and composition: the anode support layer is Toray-060 carbon paper; the VulcanXC-72 carbon powder loading in the anode microporous layer is 0.5mg / cm 2 The PTFE load is 40wt.%, screen printed on the anode support layer; the anode catalyst layer is 60wt.% Pt / C (JM), where the Pt load is 0.25mg / cm 2 ; Negative electrode is the gas diffusion electrode prepared in embodiment 2; Electrolyte membrane is Nafion212 film; Electrode effective area is 4cm 2 ; The anode, Nafion212 membrane and cathode were hot pressed at...

Embodiment 3

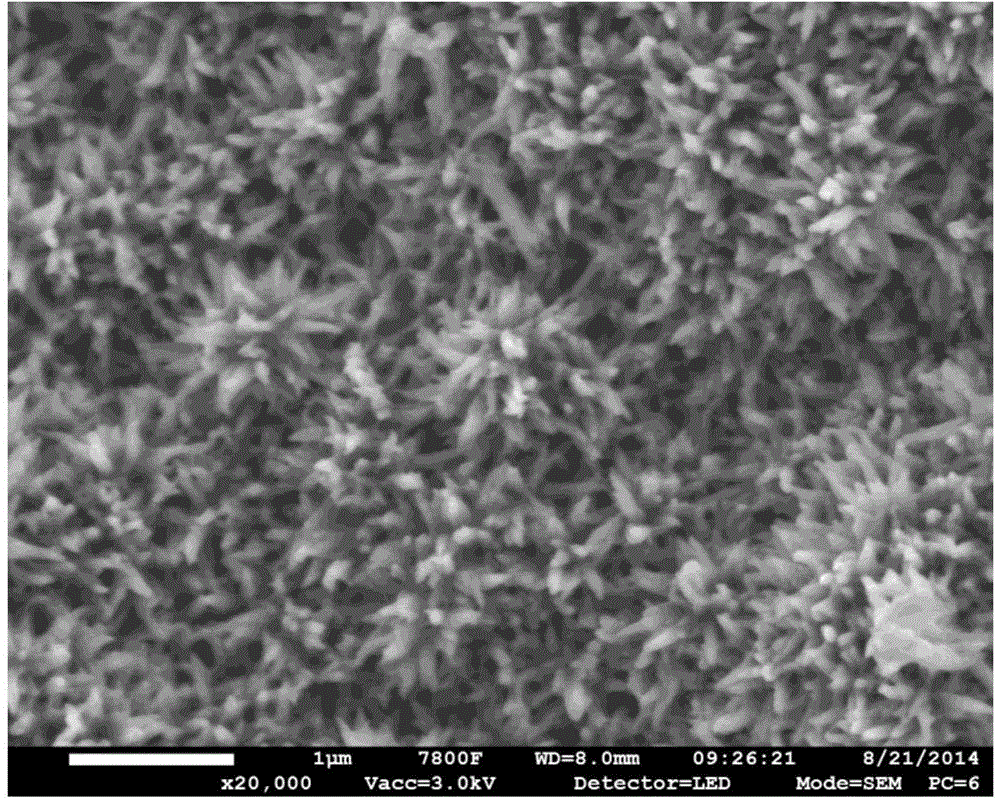

[0051] The difference from Example 1 is that the polymerization reaction temperature is 0° C., and other conditions are the same as in Example 1. The SEM characterization results of the prepared gas diffusion electrode are shown in figure 2 .

[0052] From figure 2 It can be seen from the figure that the polyaniline nanorods are perpendicular to the surface of the carbon particles, the nanorods are about 250nm in length, about 60nm in diameter, and have a sea urchin-like structure microscopically.

[0053] The IV curve of the single cell assembled with this cathode is as follows Figure 4 As shown, the single cell structure and composition, and the discharge conditions are the same as in Example 2. From Figure 4 It can be seen from the figure that the highest power density of a single cell is 392 milliwatts per square centimeter under the same test conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com