Preparation method and application of bismuth tungstate/expanded graphite sheet nanocomposite

A technology of expanded graphite sheets and composite materials, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., can solve problems such as uneven distribution, agglomeration, and influence on bonding, so as to avoid agglomeration and improve catalytic activity Improve, enhance the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of expanded graphite:

[0029] According to the mass ratio of flake graphite, concentrated sulfuric acid, hydrogen peroxide and potassium dichromate as 10:30:5:1, take samples, oxidize in a constant temperature water bath at 40°C, intercalate for 12 hours, and then use flake graphite 1:0.9HNO 3 The amount of nitric acid was added for secondary intercalation, and the reaction was continued for 30 minutes, washed with water, dried, and expanded instantaneously in a muffle furnace at 900°C to obtain expanded graphite.

Embodiment 1

[0031] First weigh 0.17g of bismuth nitrate and dissolve it in 50ml of deionized water, stir magnetically for 30min to obtain a white solution; then add 0.047g of sodium tungstate to the white solution, continue magnetically stirring for 30min to obtain a white mixed solution, add to the Add 0.2g of expanded graphite to the solution and continue magnetic stirring for 10min to obtain a black turbid solution; put the above solution into a 100ml polytetrafluoroethylene reactor, and then conduct a hydrothermal reaction at 180°C for 24h; after the reaction, take out the reactor to obtain a black precipitate in the lower layer, The upper layer clarifies the solution; the black precipitate is washed with deionized water and absolute ethanol, then dried at 80°C, and ground to obtain a bismuth tungstate / expanded graphite sheet nanostructure composite material.

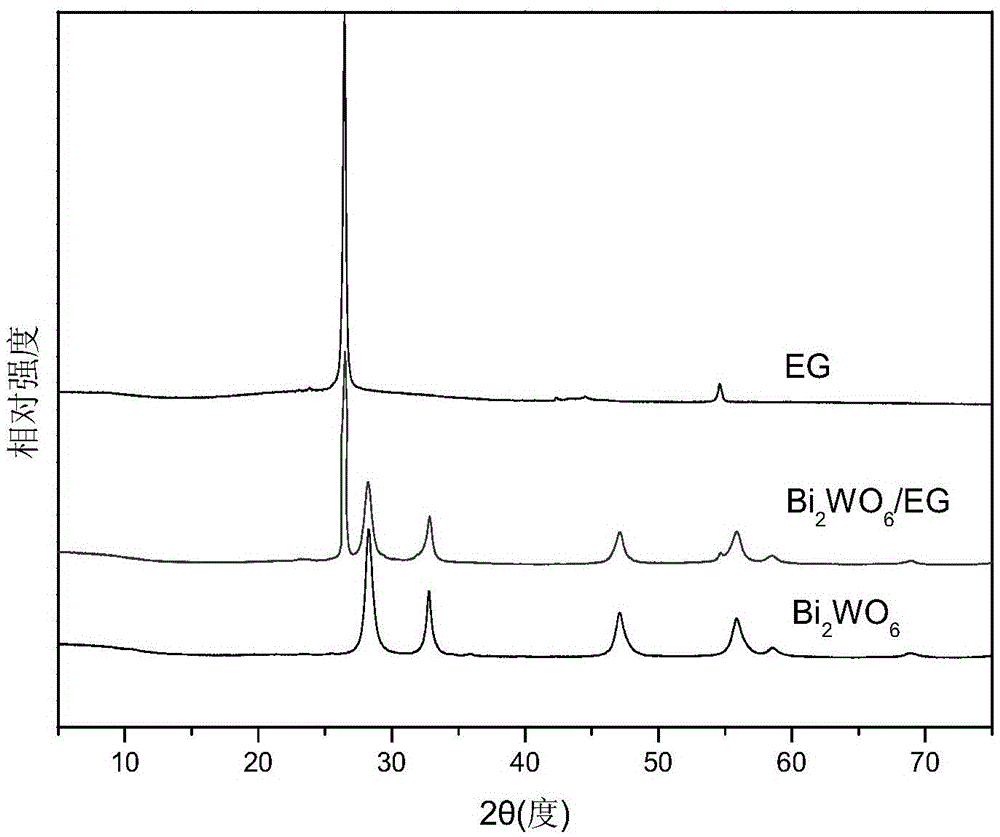

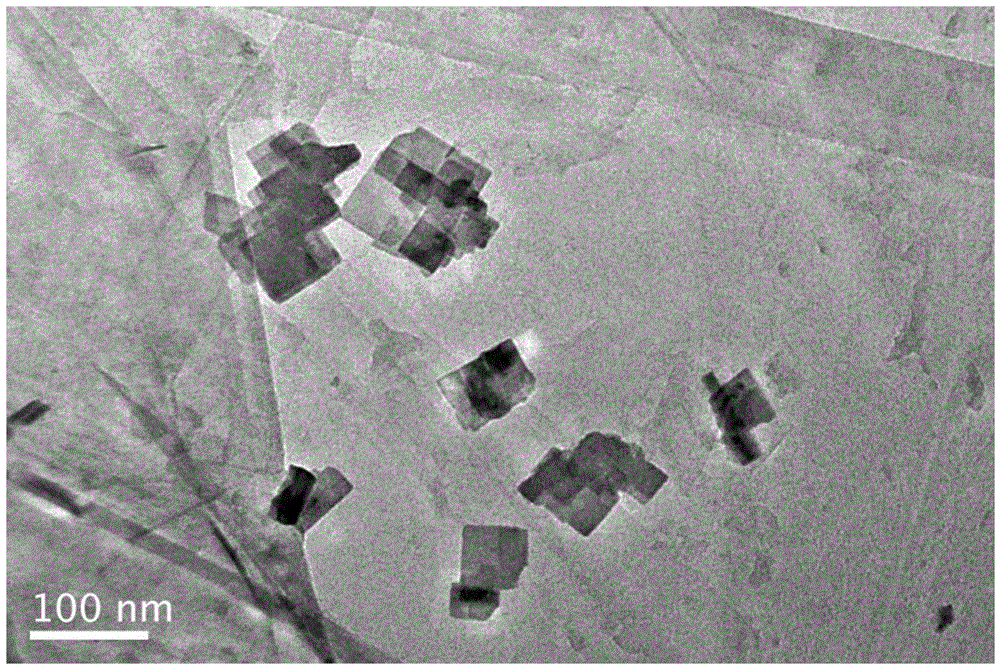

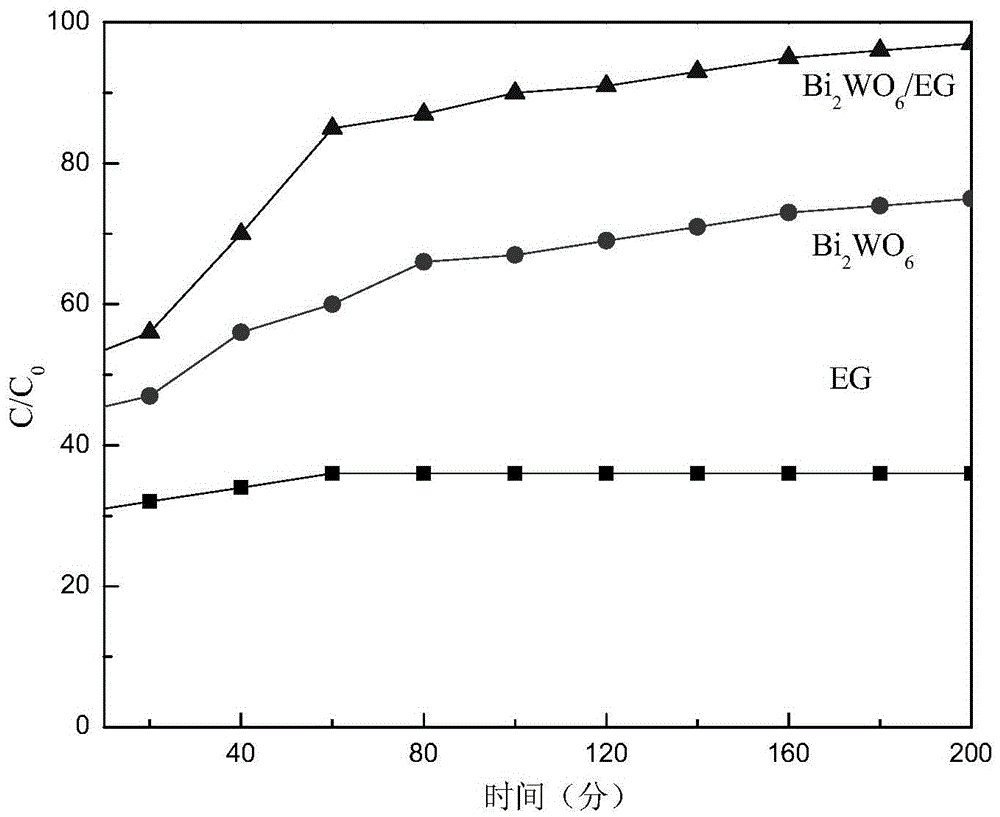

[0032] The obtained sample is subjected to X-ray powder diffraction experiment, and its morphology and structure are observed ...

Embodiment 2

[0040] Weigh 0.17g of bismuth nitrate and dissolve it in 50ml of deionized water, stir magnetically for 30min to obtain a white solution; then add 0.05g of sodium tungstate to the white solution, continue magnetically stirring for 30min to obtain a white mixed solution. Add 0.3g of expanded graphite and continue magnetic stirring for 10 minutes to obtain a black turbid solution; put the above solution into a 100ml polytetrafluoroethylene reactor, and then conduct a hydrothermal reaction at 170°C for 18 hours; after the reaction, take out the reactor to obtain a black precipitate in the lower layer, and the upper layer is clear Solution; wash the black precipitate with deionized water and absolute ethanol, then dry it at 70° C., and grind it to obtain a bismuth tungstate / expanded graphite flake nanostructure composite material. Subsequent detection is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com