A kind of synthetic method of indenonoimidazopyridine compound

A technology for imidazopyridine and ketone compounds, which is applied in organic chemistry and other fields, can solve problems such as reports and no compound synthesis methods, and achieve the effects of simple reaction operation, avoiding resource waste and environmental pollution, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

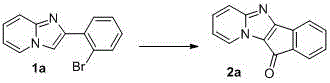

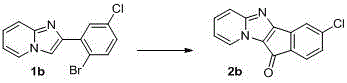

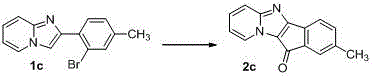

Image

Examples

Embodiment 1

[0010]

[0011] In a 15 mL Schlenk tube add 1a (0.5 mmol, 136.6 mg), DMSO (2 mL), Pd(OAc) 2 (0.05 mmol, 11.2 mg), n-butylbis(1-adamantyl)phosphine (BDAP, 0.075 mmol, 2.6 mg) and 1,4-diazabicyclo[2.2.2]octane (DABCO, 1.5 mmol, 168.3 mg). Evacuate and fill with CO, repeat three times. In an oil bath at 120°C under a CO atmosphere of 1 atm, the reaction was stirred for 12 hours, then quenched by adding 10 mL of saturated ammonium chloride solution, extracted with ethyl acetate (6 mL × 3), and then the organic phase was mixed with water and saturated saline Washed successively and dried over anhydrous sodium sulfate. It was filtered, spin-dried, and separated on a silica gel column (petroleum ether / ethyl acetate=2 / 1) to obtain the target product 2a (22 mg, 20%). The characterization data of this compound are as follows: 1 H NMR (400 MHz, CDCl 3 ) δ: 6.98 (t, J = 6.8 Hz, 1H), 7.19 (t, J = 7.6 Hz,1H), 7.29-7.40 (m, 4H), 7.60 (d, J = 8.8 Hz, 1H), 8.38 (d, J = 6.4 Hz, ...

Embodiment 2

[0013] In a 15 mL Schlenk tube add 1a (0.5 mmol, 136.6 mg), DMSO (2 mL), Pd(OAc) 2 (0.05 mmol, 11.2 mg), triphenylphosphine (0.075 mmol, 19.7 mg) and DABCO (1.5 mmol, 168.3 mg). Evacuate and fill with CO, repeat three times. Stir the reaction in an oil bath at 120°C under a CO atmosphere of 1 atm for 12 hours, add 10 mL of saturated ammonium chloride solution to quench the reaction, extract with ethyl acetate (6 mL × 3), and then the organic phase is washed with water and saturated brine successively Washed and dried over anhydrous sodium sulfate. It was filtered, spin-dried, and separated on a silica gel column (petroleum ether / ethyl acetate=2 / 1) to obtain the target product 2a (33 mg, 33%).

Embodiment 3

[0015] In a 15 mL Schlenk tube add 1a (0.5 mmol, 136.6 mg), DMSO (2 mL), Pd(OAc) 2 (0.05 mmol, 11.2 mg), tricyclohexylphosphine (TCHP, 0.075 mmol, 21 mg) and DABCO (1.5 mmol, 168.3 mg). Evacuate and fill with CO, repeat three times. Stir the reaction in an oil bath at 120°C under a CO atmosphere of 1 atm. After stirring for 12 hours, add 10 mL of saturated ammonium chloride solution to quench the reaction, extract with ethyl acetate (6 mL × 3), and then the organic phase is sequentially washed with water and saturated brine. Washed and dried over anhydrous sodium sulfate. It was filtered, spin-dried, and separated on a silica gel column (petroleum ether / ethyl acetate=2 / 1) to obtain the target product 2a (31.9 mg, 29%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com