Preparation method of nano-encapsulated phase change material

A phase change material and nanocapsule technology, applied in the field of nanomaterials, can solve the problems of long preparation time, complicated experimental process, and unsuitable for large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

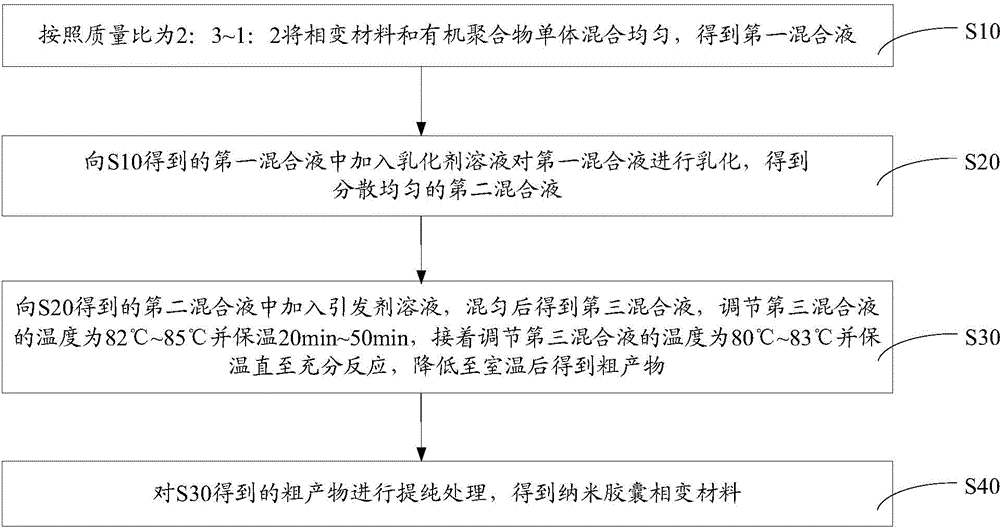

[0029] like figure 1 The preparation method of the nanocapsule phase-change material of one embodiment shown, comprises the steps:

[0030] S10, uniformly mixing the phase change material and the acrylic ester according to a mass ratio of 2:3˜1:2 to obtain a first mixed liquid.

[0031] The phase change material is an alkane phase change material with a phase change temperature between 20°C and 30°C.

[0032] Specifically, the phase change material may be liquid paraffin. In this embodiment, the phase change material is liquid paraffin with a phase change temperature of 20°C.

[0033] The acrylic ester may be methyl methacrylate.

[0034] The homogeneous mixing operation of phase change material and acrylic ester can be realized by ultrasonic dispersion.

[0035] S20. Adding an emulsifier solution to the first mixed liquid obtained in S10 to emulsify the first mixed liquid to obtain a uniformly dispersed second mixed liquid.

[0036] The mass ratio of the emulsifier in th...

Embodiment 1

[0053] Mix 7.5 g of liquid paraffin and 12.10 g of methyl methacrylate, and uniformly disperse by ultrasonic for 5 min to obtain a first mixed solution.

[0054] Add 1 g of sodium dodecyl benzene sulfonate to 42.5 mL of deionized water to disperse uniformly, and add it to the first mixed solution and mix evenly for 10 minutes. Mechanical stirring was performed, and then the reaction system was heated to 80° C. and kept for 30 minutes to form a uniformly dispersed milky white microemulsion, which was the second mixed solution. Mechanical agitation was accomplished with a sheet-mounted stainless steel stirring rod, and the mechanical stirring speed was 600 rpm / min.

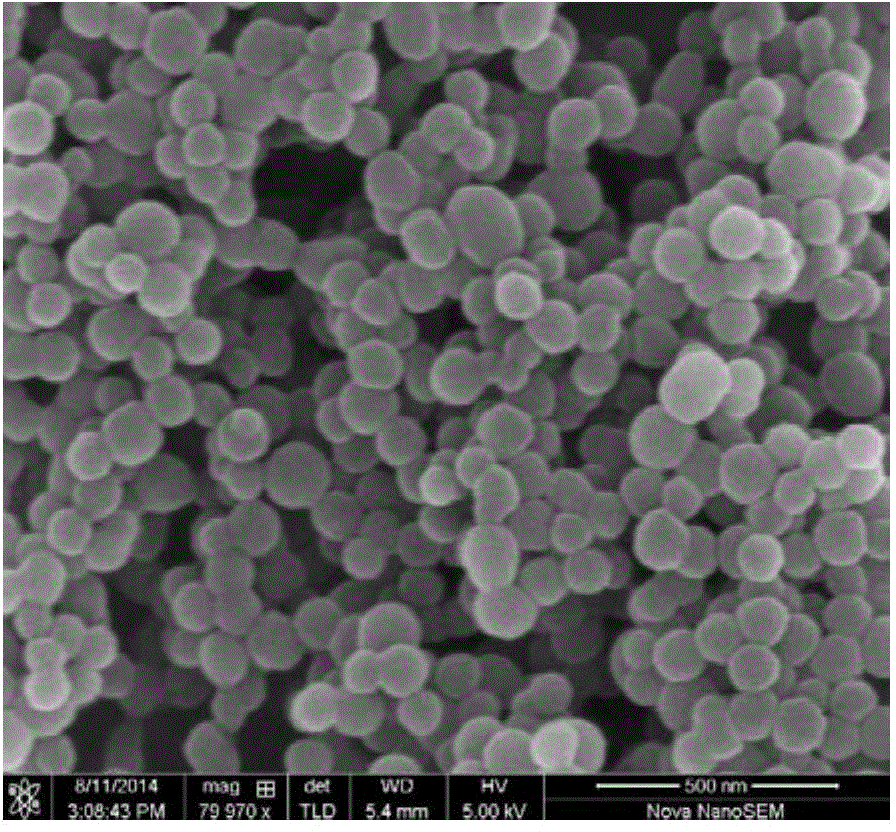

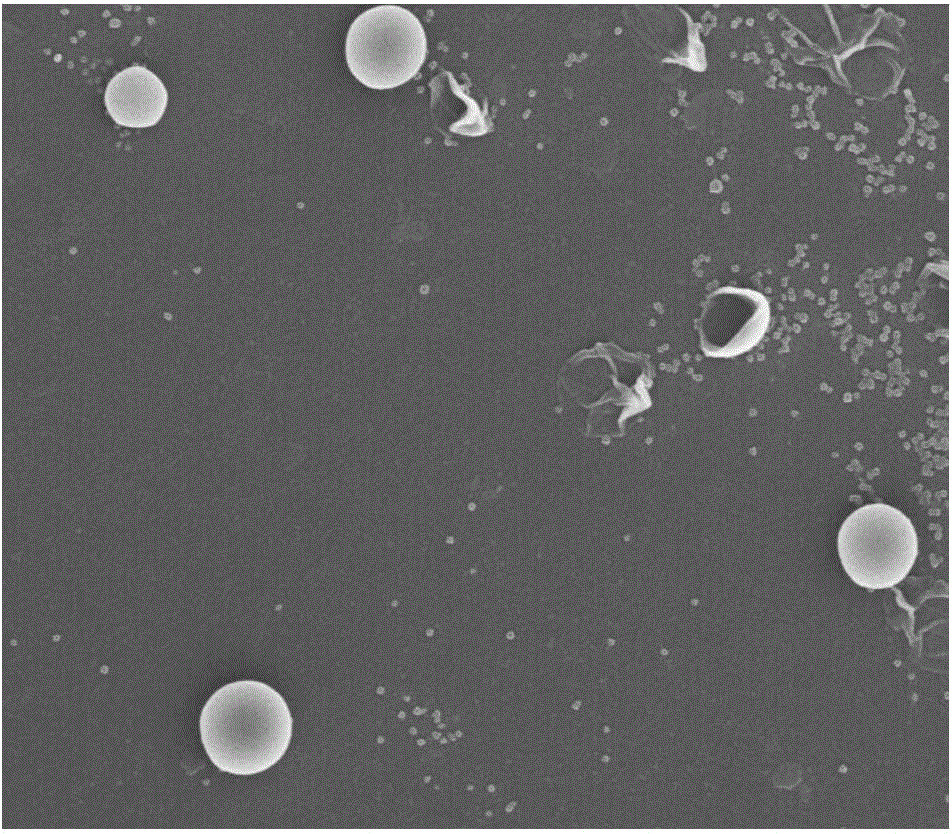

[0055] 1 g of ammonium persulfate was dissolved in 7.5 mL of deionized water and slowly added dropwise to the second mixture. After the dropwise addition is completed, the third mixed solution is obtained after mixing, and the temperature of the third mixed solution is adjusted to 85 ° C and kept for 30 min, then t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com