Foam concrete composite lightweight partition batten and preparation method thereof

A technology of lightweight partition wall slats and foam concrete, which is applied in the field of building materials, can solve the problems of high cost, large capacity of the surface layer of calcium silicate board, and easy shrinkage and cracking of the sandwich layer, so as to reduce the overall surface density and benefit Energy-saving heat preservation effect, the effect of solving the problem of bonding compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036]The preparation method of the phase change stabilization material is as follows: 1) heating and stirring butyl stearate and ultra-light aggregate in a vacuum kettle evenly, the mass ratio is 2:1, and the control temperature is 30°C; 2) Keep the pressure for 5 minutes under the negative pressure condition of 0.2Mpa, then gradually lower the temperature in the kettle to 0°C, and return to normal pressure; 3) cycle 3 times for temperature rise, pressure drop, temperature drop, and return to normal pressure in this way; 4) Control the characteristics after treatment Gently aggregate the material at a temperature of ≤10°C, and coat the surface with epoxy resin to obtain the phase change stabilization material.

[0037] The extra light aggregate is expanded perlite with a bulk density of 100kg / m 3 .

Embodiment 1

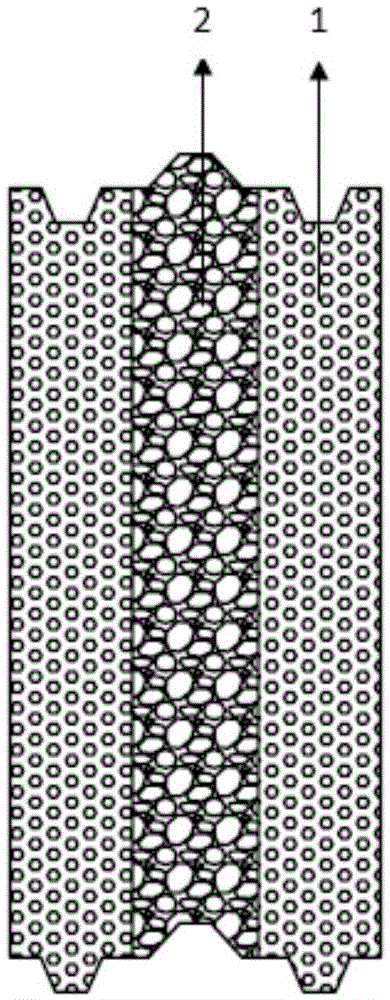

[0043] A kind of foam concrete composite lightweight partition wall slab, it is made of panel foam concrete 1 and core body foam concrete 2 (see figure 1 ), wherein the panel foam concrete 1 is symmetrically arranged on the left and right sides of the core foam concrete 2, and the thickness of the panel foam concrete 1 and the core foam concrete 2 is 3cm.

[0044] The mass percentage of each component in the panel foam concrete is: cement 47%, admixture 18%, ultra-light aggregate 8.83%, water 26%, fiber 0.03%, foam stabilizer 0.02%, water repellent 0.02% %, foaming agent 0.10%; the mass percentage of each component in the core foam concrete is: cement 35%, admixture 27%, phase change stabilization material 10.82%, water 27%, fiber 0.01%, foam stabilizer Agent 0.02%, foaming agent 0.15%.

[0045] Prepare panel foam concrete and core body foam concrete slurry according to the above method, and perform pouring and molding of foam concrete composite lightweight partition wall str...

Embodiment 2

[0052] A foam concrete composite lightweight partition wall slab, which is composed of panel foam concrete and core foam concrete, wherein the panel foam concrete is symmetrically arranged on the left and right sides of the core foam concrete, and the thickness of the panel foam concrete and the core foam concrete is equal. It is 4cm. Concrete mixing and pouring of foam concrete composite lightweight partition wall strips are carried out according to the mix ratio of panel foam concrete and core foam concrete described in Example 1.

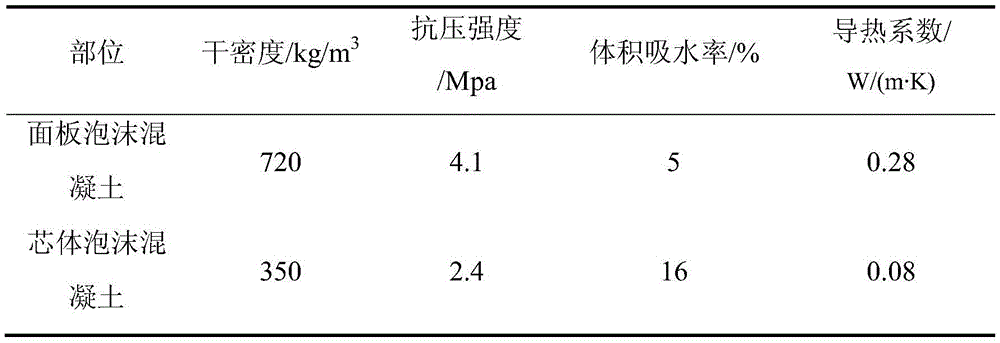

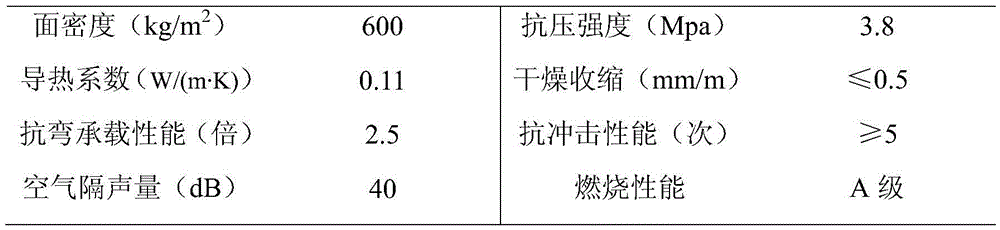

[0053] According to "Foamed Concrete for Roof Thermal Insulation" (JC / T2125-2012), the bulk density, compressive strength, water absorption, thermal conductivity and other properties of the face foam concrete slab and core foam concrete were tested, and the results are shown in Table 3. According to "Lightweight Partition Wall Slats for Buildings" (GB / T2451-2009), the foam concrete composite lightweight partition wall slats obtained in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com