Preparation method of monodisperse quantum dot micro spheres with optical gain property

A technology of optical gain and quantum dots, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of improving sphericity and stability, improving stability, and not being easily oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

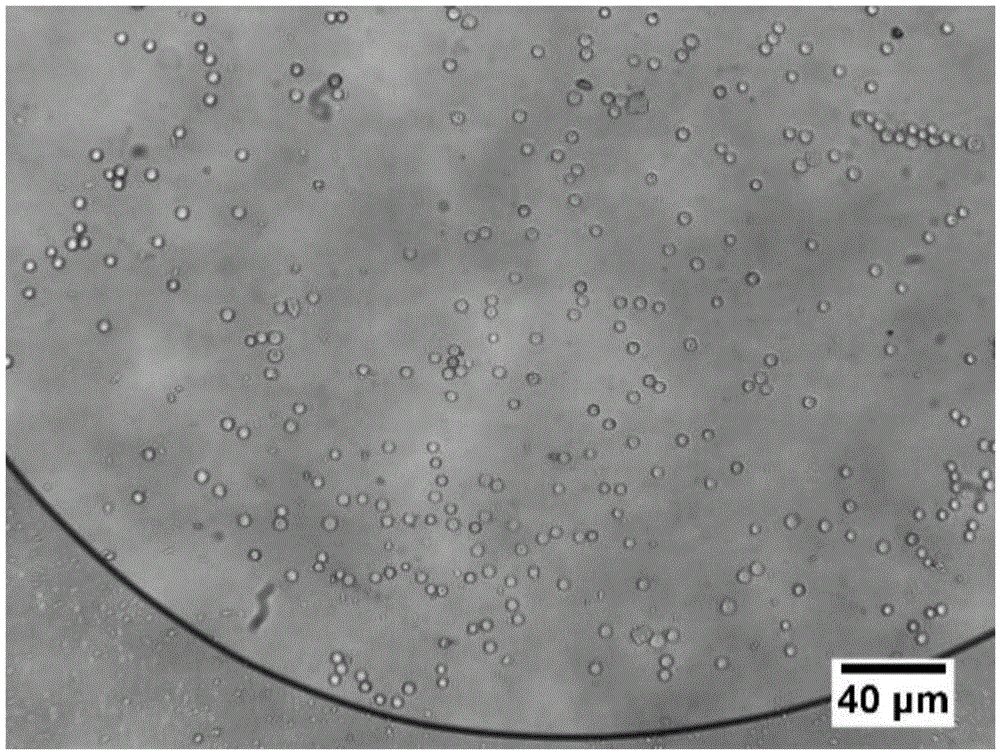

[0044] (1) SiO containing 0.2wt% average particle size of 20nm and 10% standard deviation of particle size distribution 2 20 mL of the aqueous phase of nanospheres and 0.05 wt % cetyltrimethylammonium bromide was placed in a beaker and fully dispersed under magnetic stirring. Disperse 10 mg of CdS / ZnS quantum dots with a fluorescence emission peak width of 20 nm, 200 μL of vinyltrimethoxysilane, and 0.5 g of methyl methacrylate into 5 mL of anhydrous toluene, and transfer them to the pressure tank of the membrane emulsifier after the dispersion is uniform .

[0045] (2) Select a membrane with an average pore diameter of 1.4 μm, and adjust the pressure to 48 kPa for emulsification.

[0046] (3) Add 0.005g of photoinitiator 2-hydroxyl-2-methyl-1-phenylacetone to the emulsion, place the stable emulsion under the ultraviolet light curing instrument, and under the action of stirring, trigger methyl Methyl acrylate was polymerized for 2h to obtain PMMA.

[0047] (4) The solidifie...

Embodiment 2

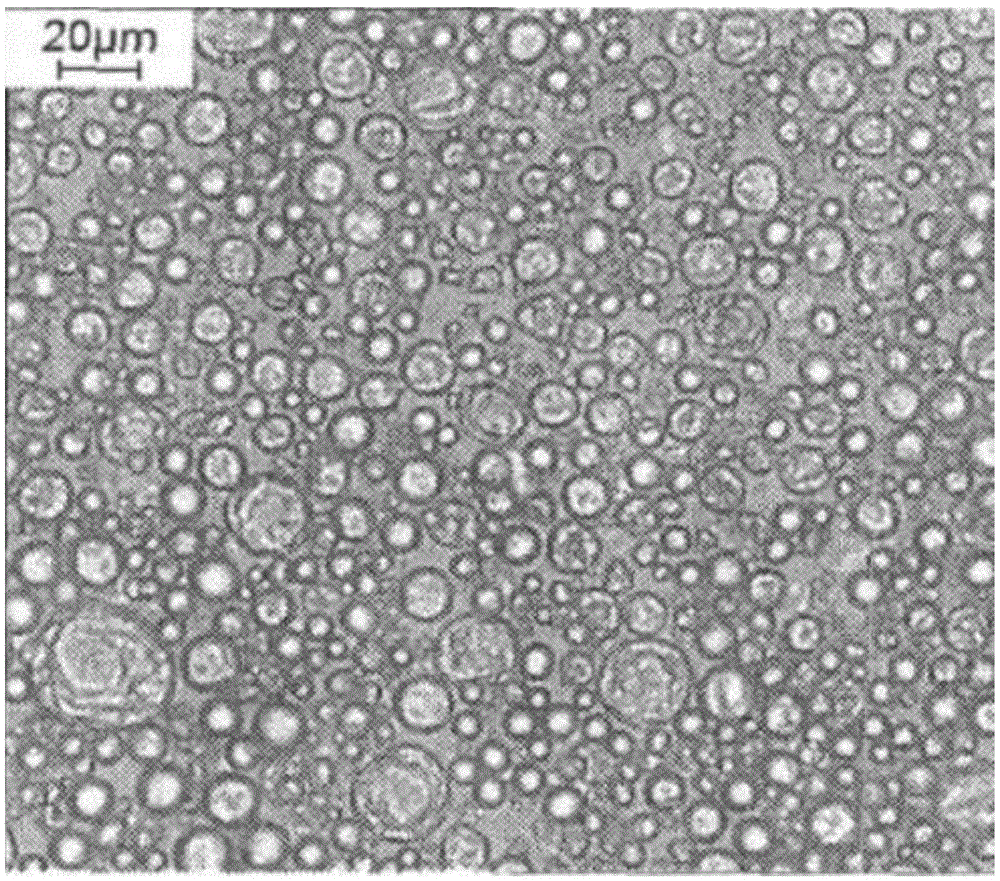

[0050] (1) TiO with 2wt% average particle diameter of 100nm and 10% standard deviation of particle size distribution 2 10 mL of the aqueous phase of nanospheres and 0.1 wt % sodium dodecylsulfonate was placed in a beaker and fully dispersed under magnetic stirring. Disperse 10 mg of CdSe / ZnS quantum dots with a fluorescence emission peak width of 24 nm, 5 mg of CdS / ZnS quantum dots, 500 μL of hexadecyltrichlorosilane, 1 g of styrene, and 0.01 g of initiator azobisisobutyronitrile into 5 mL of anhydrous In octane, after being uniformly dispersed, it is transferred to the pressure tank of the membrane emulsifier.

[0051] (2) Select a membrane with an average pore diameter of 2.5 μm, and adjust the pressure to 24 kPa for emulsification.

[0052] (3) Slowly raise the temperature of the stable emulsion to 80° C. under the action of stirring, and stabilize it for 8 hours to polymerize to obtain PS.

[0053] (4) The solidified microspheres were centrifuged, washed 3 times with wat...

Embodiment 3

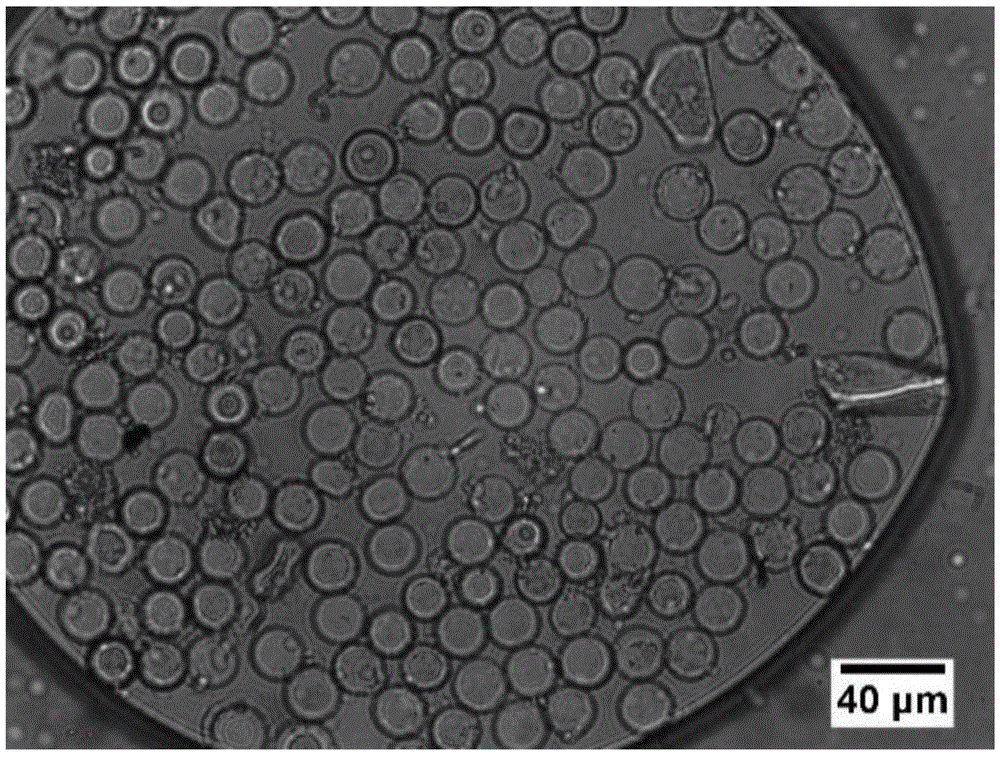

[0056] (1) the aqueous phase 10mL that will contain 10wt% average particle diameter is 200nm, the PVP nanosphere of particle size distribution standard deviation 10%, 1wt% Tween-80, 0.5wt% sodium dodecylsulfonate is placed in the beaker, Thoroughly disperse under magnetic stirring. 20 mg of CuInS with a fluorescence emission peak width of 110 nm 2 / ZnS quantum dots, 1mL octyltriethoxysilane, 1.5g of 2,4'-toluene diisocyanate, 0.005 initiator azobisisobutyronitrile are dispersed in 10mL of anhydrous DMF, and transferred to the membrane after the dispersion is uniform In the pressure tank of the emulsifier.

[0057] (2) Select a membrane with an average pore diameter of 6.6 μm, and adjust the pressure to 5 kPa for emulsification.

[0058] (3) The stable emulsion was cured for 1 hour under a UV curing apparatus to obtain PU, and the temperature was slowly raised to 70° C. under the action of stirring, and stabilized for 4 hours.

[0059] (4) The solidified microspheres were ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com