Preparation method of HNTs, method used for preparing high polymer/HNTs mixed solution from HNTs, and method used for preparing high polymer nanofiber from high polymer/HNTs mixed solution

A mixed liquid and high polymer technology, applied in the polymer field, can solve the problems of poor polymer compatibility, poor dispersion, and limited application range, etc., achieve good thermal stability and acid-base stability, and enhance mechanical properties , Improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 90g of HNTs powder calcined at 500°C and sieved at 500 mesh, 1g of modified sulfonate wetting agent and 9g of polycarboxylate dispersant in a sand mill, add 360g of water, and the speed of the sand mill is 1460r / min, sand mill for 2h to form a suspension dispersion of 20-30nm. Dehydration and granulation were carried out by using two-fluid spray drying equipment, with an inlet temperature of 170°C, an outlet temperature of 80°C, and a pressure of 0.3MPa to obtain surface-modified HNTs powder.

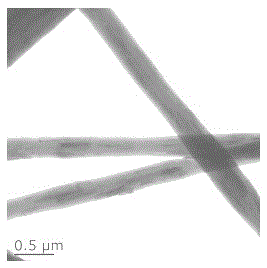

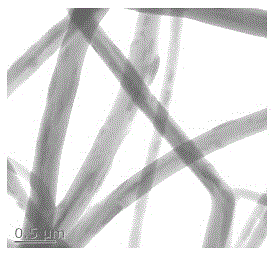

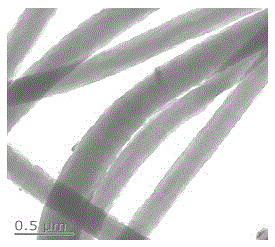

[0024] Weigh 4g of PVA and dissolve it in 36g of water to prepare a 10% PVA aqueous solution. After the PVA is completely dissolved, add 10% of modified HNTs (relative to the mass fraction of the PVA aqueous solution), and stir for 2 hours until the dispersion is uniform. Put the PVA / HNT mixture in a disposable syringe, set up the electrospinning device, adjust the voltage to 12kv, push the speed to 0.2mm / min, start electrospinning, and obtain polymer / HNTs composite fibers...

Embodiment 2

[0026] Weigh 90g of HNTs powder calcined at 450°C and sieved at 600 mesh, 1g of modified sulfonate wetting agent and 9g of polycarboxylate dispersant in a sand mill, add DMF300g, and the speed of the sand mill is 800r / min, sand mill for 2h to form a suspension dispersion of 20-30nm. Dehydration and granulation were carried out by using two-fluid spray drying equipment, with an inlet temperature of 170°C, an outlet temperature of 80°C, and a pressure of 0.3MPa to obtain surface-modified HNTs powder.

[0027] Weigh 5g of PMMA and dissolve it in 15g of water to prepare a 25% PMMA-DMF solution. After the PMMA is completely dissolved, add 15% of modified HNTs (relative to the mass fraction of the PMMA-DMF solution), and stir for 2 hours until the dispersion is uniform. Put the PMMA / HNTs mixture in a disposable syringe, set up the electrospinning device, adjust the voltage to 19kv, and the driving speed to 0.3mm / min, start electrospinning, and obtain PMMA / HNTs composite fibers afte...

Embodiment 3

[0029] Weigh 80g of HNTs powder that has been roasted at 800°C and sieved with 600 mesh, 2g of naphthalenesulfonate wetting agent and 10g of polycarboxylate dispersant in a sand mill, add 300g of water, and the speed of the sand mill is 2000r / min , Sand milled for 2h to form a suspension dispersion of 20-30nm. Dehydration and granulation were carried out using a two-fluid spray drying equipment, with an inlet temperature of 180°C, an outlet temperature of 70°C, and a pressure of 0.25MPa to obtain surface-modified HNTs powder. The HNTs powder was further modified with a coupling agent to obtain HNTs powder with hydrophobic surface.

[0030] Weigh 5g of PAN and dissolve it in 35g of DMF to prepare a 12.5% PAN solution. After the PAN is completely dissolved, add 10% of modified HNTs (relative to the mass fraction of the PAN solution), and stir for 2 hours until the dispersion is uniform. Put the PAN / HNTs mixture in a disposable syringe, set up the electrospinning device, adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com