Lasting efficient anti-ultraviolet finishing agent and preparation method thereof

An anti-ultraviolet and finishing agent technology, applied in fiber treatment, improved handle fibers, textiles and papermaking, etc., can solve the problems of high production cost, complicated preparation process, affecting the hand feel of textiles, etc., and achieve low equipment requirements and simple preparation methods , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

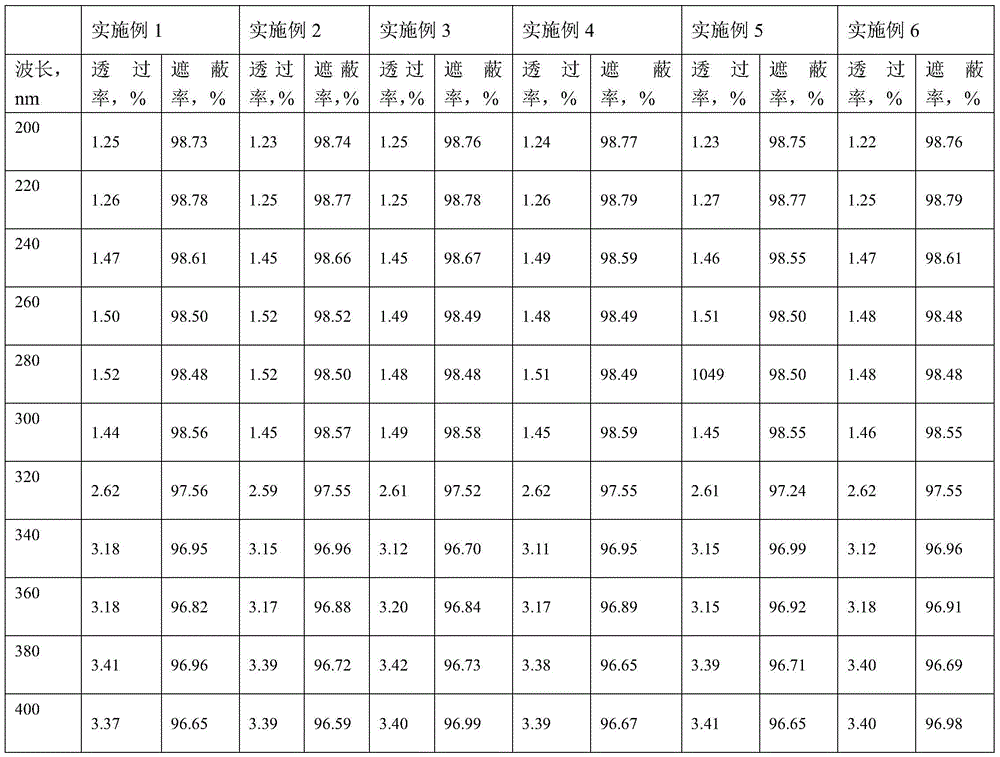

Examples

Embodiment 1

[0042] A durable and effective anti-ultraviolet finishing agent, in parts by weight, comprising the following components:

[0043] 10 parts of fluorocarbon emulsion, 5 parts of substituted benzotriazole,

[0044] 2 parts of sodium polyacrylate, 3 parts of p-aminobenzoic acid,

[0045] 5 parts of tea polyphenols, 8 parts of aloe extract,

[0046] 3 parts of alkyl glycoside, 5 parts of sodium lactate,

[0047] 2 parts of dispersant, 1 part of defoamer, 30 parts of deionized water.

[0048] Its preparation method comprises the following steps:

[0049] (1) Mix and stir the fluorocarbon emulsion, substituted benzotriazole, sodium polyacrylate, p-aminobenzoic acid and deionized water evenly, raise the temperature to 40°C, continue stirring for 2 hours, and cool to room temperature to obtain a mixed emulsion;

[0050] (2) Mix and stir tea polyphenols, aloe extract, alkyl glucoside, sodium lactate and deionized water evenly, and ultrasonicate for 1 hour at a power of 500W to obta...

Embodiment 2

[0053] A durable and effective anti-ultraviolet finishing agent, in parts by weight, comprising the following components:

[0054] 20 parts of fluorocarbon emulsion, 8 parts of substituted benzotriazole,

[0055] 5 parts of sodium polyacrylate, 5 parts of p-aminobenzoic acid,

[0056] 15 parts of tea polyphenols, 15 parts of aloe extract,

[0057] 7 parts of alkyl glycosides, 10 parts of sodium lactate,

[0058] 3 parts of dispersant, 3 parts of defoamer, 50 parts of deionized water.

[0059] Its preparation method comprises the following steps:

[0060] (1) Mix and stir the fluorocarbon emulsion, substituted benzotriazole, sodium polyacrylate, p-aminobenzoic acid and deionized water evenly, raise the temperature to 50°C, continue stirring for 3 hours, and cool to room temperature to obtain a mixed emulsion;

[0061] (2) Mix and stir tea polyphenols, aloe extract, alkyl glycoside, sodium lactate and deionized water evenly, and ultrasonicate for 2 hours at a power of 500W t...

Embodiment 3

[0064] A durable and effective anti-ultraviolet finishing agent, in parts by weight, comprising the following components:

[0065] 15 parts of fluorocarbon emulsion, 6 parts of substituted benzotriazole,

[0066] 3.5 parts of sodium polyacrylate, 3 parts of p-aminobenzoic acid,

[0067]10 parts of tea polyphenols, 11 parts of aloe extract,

[0068] 5 parts of alkyl glycoside, 10 parts of sodium lactate,

[0069] 2 parts of dispersant, 1 part of defoamer, 40 parts of deionized water.

[0070] Its preparation method comprises the following steps:

[0071] (1) Mix and stir the fluorocarbon emulsion, substituted benzotriazole, sodium polyacrylate, p-aminobenzoic acid and deionized water evenly, raise the temperature to 45°C, continue stirring for 2.2 hours, and cool to room temperature to obtain a mixed emulsion;

[0072] (2) Mix and stir tea polyphenols, aloe extract, alkyl glucoside, sodium lactate and deionized water evenly, and ultrasonicate for 1.2 hours at a power of 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com