High-strength composite base plate system and preparation process

A technology of high-strength composite material and backing plate, which is used in buildings, roads, special pavements, etc., can solve the problems of poor toughness and impact resistance of cement backing plates, low strength of connecting parts, poor aging resistance of materials, etc., and achieves convenient installation and handling. Excellent mechanical properties and improved aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

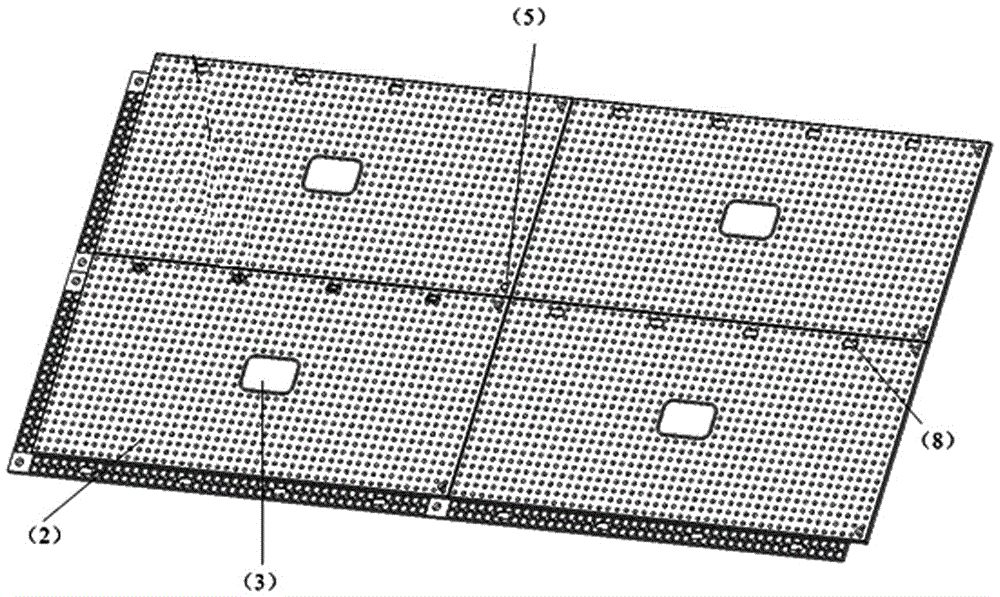

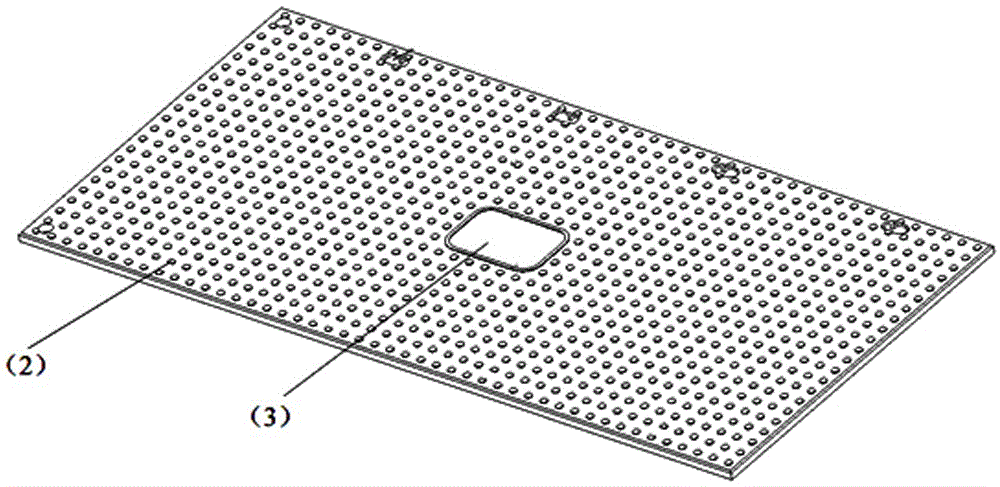

[0031] Embodiment 1, in conjunction with attached Figure 1-8 , to further describe the present invention:

[0032] A high-strength composite material backing system mentioned in the present invention includes high-strength composite material plates made of high-density polyethylene (HDPE) and ultra-high molecular weight polyethylene (UHMWPE) through molding process, standard connection module 8, positioning chip The groove cover 9, the outer surface of the high-strength composite material plate is designed with anti-slip lines 2, and its structure is divided into two types: solid structure and back grid-like rib structure, wherein the backing plate of the solid structure is a plane shape 4; The backing plate of the grid-like rib structure adopts a single plate or a composite structure of two plates, wherein the grid-like rib structure on the back is designed as an arrayed square groove 6 and an independent strip groove 7 .

[0033] Among them, the formulation of the high-str...

Embodiment 2

[0046] Example 2: The difference from Example 1 is that the formulation of the high-strength composite material sheet of the present invention is mainly prepared by mixing the following components in weight percentages: 70 parts of high-density polyethylene resin, ultra-high molecular weight polyethylene resin 20 parts of vinyl resin, 10 parts of filler, 2 parts of low shrinkage agent, 5 parts of color paste, 3 parts of release agent, 5 parts of anti-ultraviolet absorber; The molecular weight of the material is 5 million.

Embodiment 3

[0047] Example 3: The difference from Example 1 is that the formulation of the high-strength composite material sheet of the present invention is mainly prepared by mixing the following components in weight percentages: 65 parts of high-density polyethylene resin, ultra-high molecular weight polyethylene resin 18 parts of vinyl resin, 7 parts of filler, 1.5 parts of low shrinkage agent, 3.5 parts of color paste, 2 parts of release agent, 4 parts of anti-ultraviolet absorber; The molecular weight of the material is 3 million, which is different according to the design strength of the backing plate. The higher the strength design requirements of the backing plate, the greater the molecular weight of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com